Optical sheet, backlight unit for liquid crystal display apparatus and method for manufacturing optical sheet

A technology of optical sheets and optical functional layers, which is applied in the field of optical sheets, can solve problems such as the decrease of front brightness, and achieve the effect of improving quality and excellent optical functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

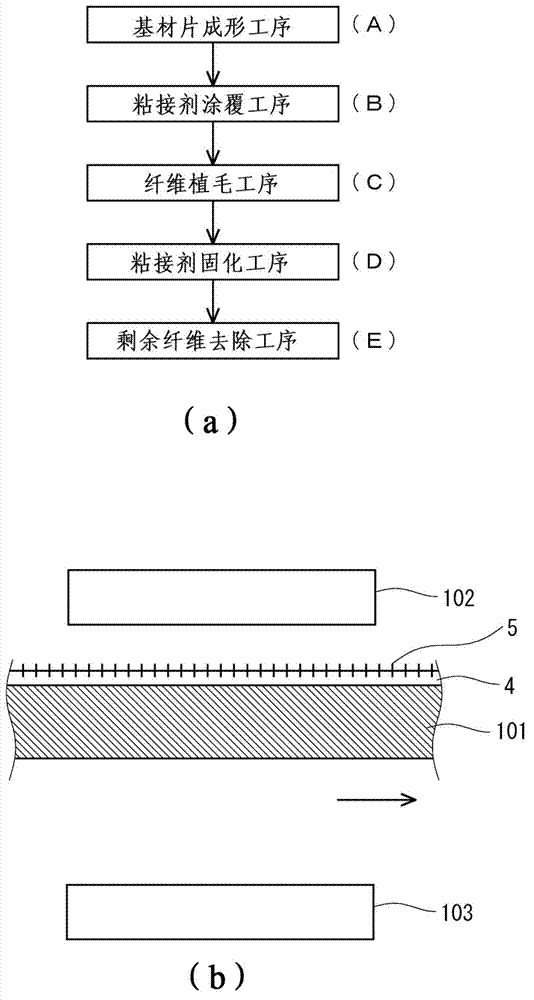

Method used

Image

Examples

Embodiment approach

[0083] The optical sheet of the present invention is not limited to the above-described embodiments, and the following embodiments may be employed.

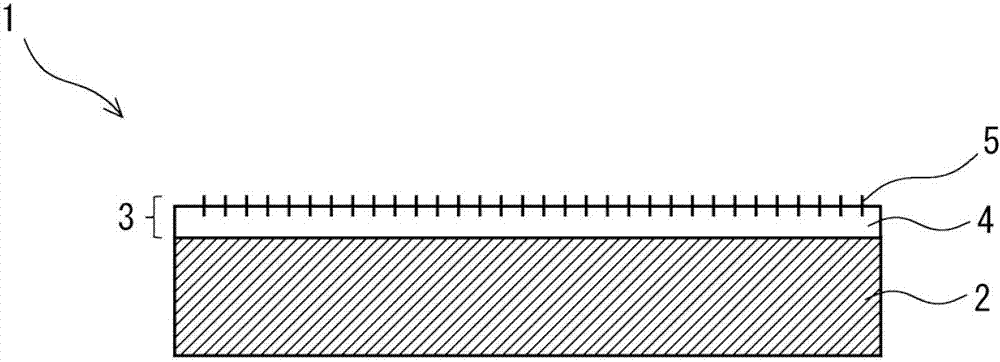

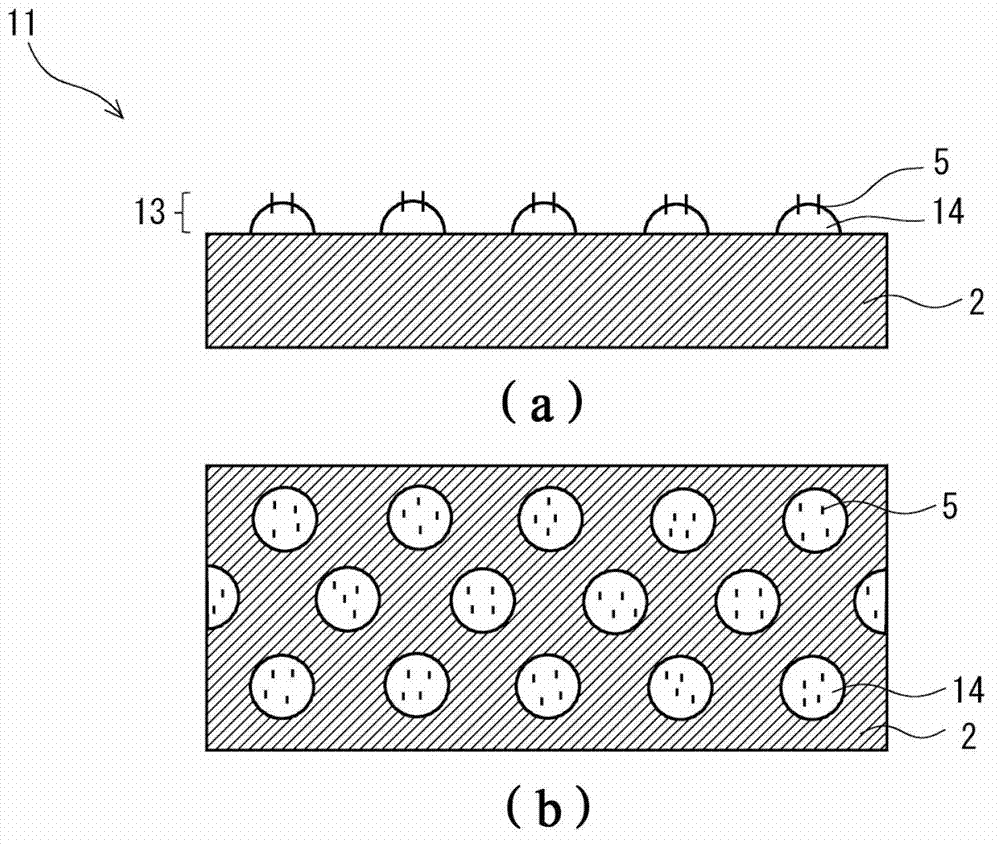

[0084] image 3 The optical sheet 11 is a so-called light diffusion sheet, and includes a base material layer 2 and an optical function layer 13 arranged on the surface of the base material layer 2 . The optical function layer 13 includes: an adhesive part 14 ; a plurality of fibers 5 protruding from the base material layer 2 through the adhesive part 14 ; and air sandwiched between the plurality of fibers 5 . The base material layer 2, the manufacturing method of the sheet, the adhesive agent forming the adhesive portion 14, the material of the fiber 5, etc. are the same as those described above. figure 1 The optical sheets 1 are the same, so their descriptions are omitted.

[0085] The plurality of fibers 5 protrude from the surface of the base material layer 2 through the plurality of adhesive portions 14 provided in scatte...

Embodiment 1

[0103] Adhesive ("E263" manufactured by Dainichi Seika Co., Ltd.) is applied to the surface of the substrate layer by a roll coating method, and polyamide fibers are implanted by electrostatic tufting. The material of the substrate layer is polyethylene terephthalate, and the thickness is 100 μm. The surface density of the fiber substrate layer is 3500 fibers / cm 2 , with an average diameter of 10 μm and an average length of 50 μm.

[0104] The optical sheet of Example 1 was irradiated with a backlight, and the total light transmittance was measured in accordance with JIS K7361, and the result was 79%. In addition, haze was measured in accordance with JIS K7105, and the result was 86%.

Embodiment 2

[0106] Using the same substrate layer and adhesive as in Example 1, polyester fibers were implanted by electrostatic hair transplantation. The density of the surface of the fiber substrate layer is 3000 fibers / cm 2 , with an average diameter of 10 μm and an average length of 50 μm.

[0107] The optical sheet of Example 2 was irradiated with a backlight, and the total light transmittance was measured according to JIS K7361, and the result was 82%. In addition, haze was measured in accordance with JIS K7105, and the result was 87%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com