Cable reel

A wire reel and cable technology, which is applied in the direction of bendable lead devices, current collectors, electrical components, etc. The effect of uniformity, improved withstand voltage, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

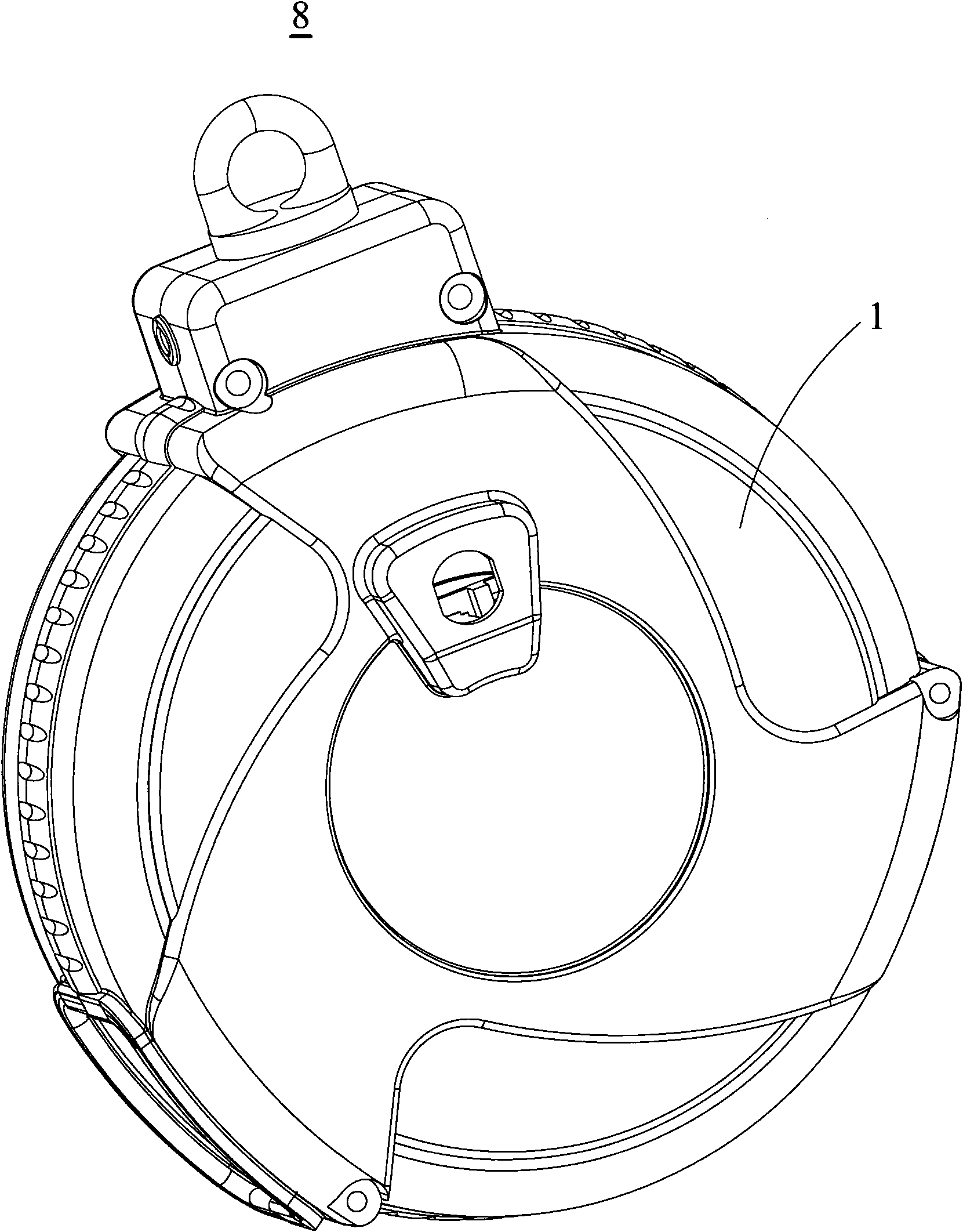

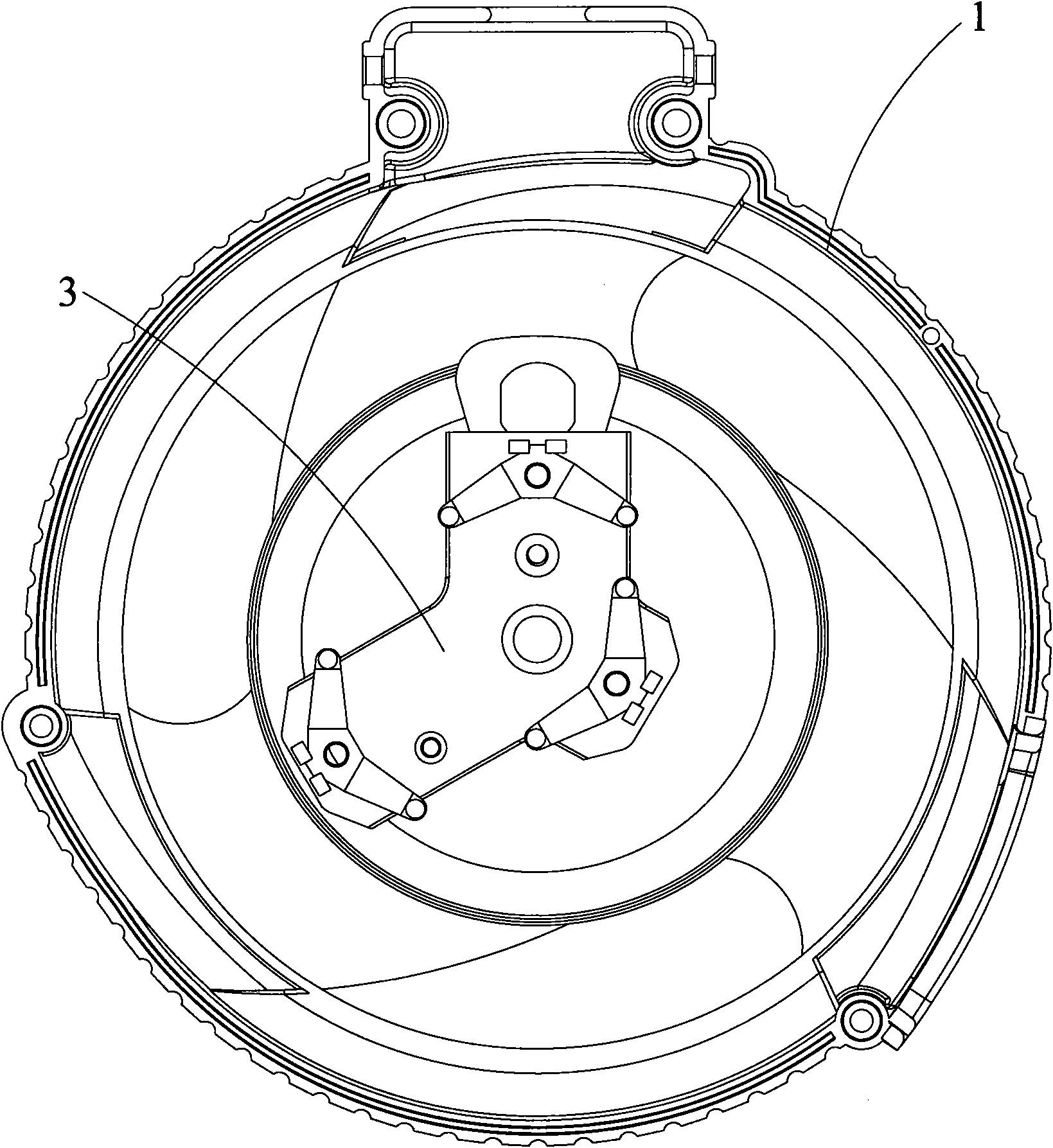

[0014] see Figure 1-Figure 5 As shown, the wire reel 8 of the present invention includes a housing 1 , a runner (not shown), cables (not shown), a track module 2 and a terminal module 3 accommodated in the housing 1 . The cable is wound on the wheel, and one end is electrically connected to the track module 2 or the terminal module 3 .

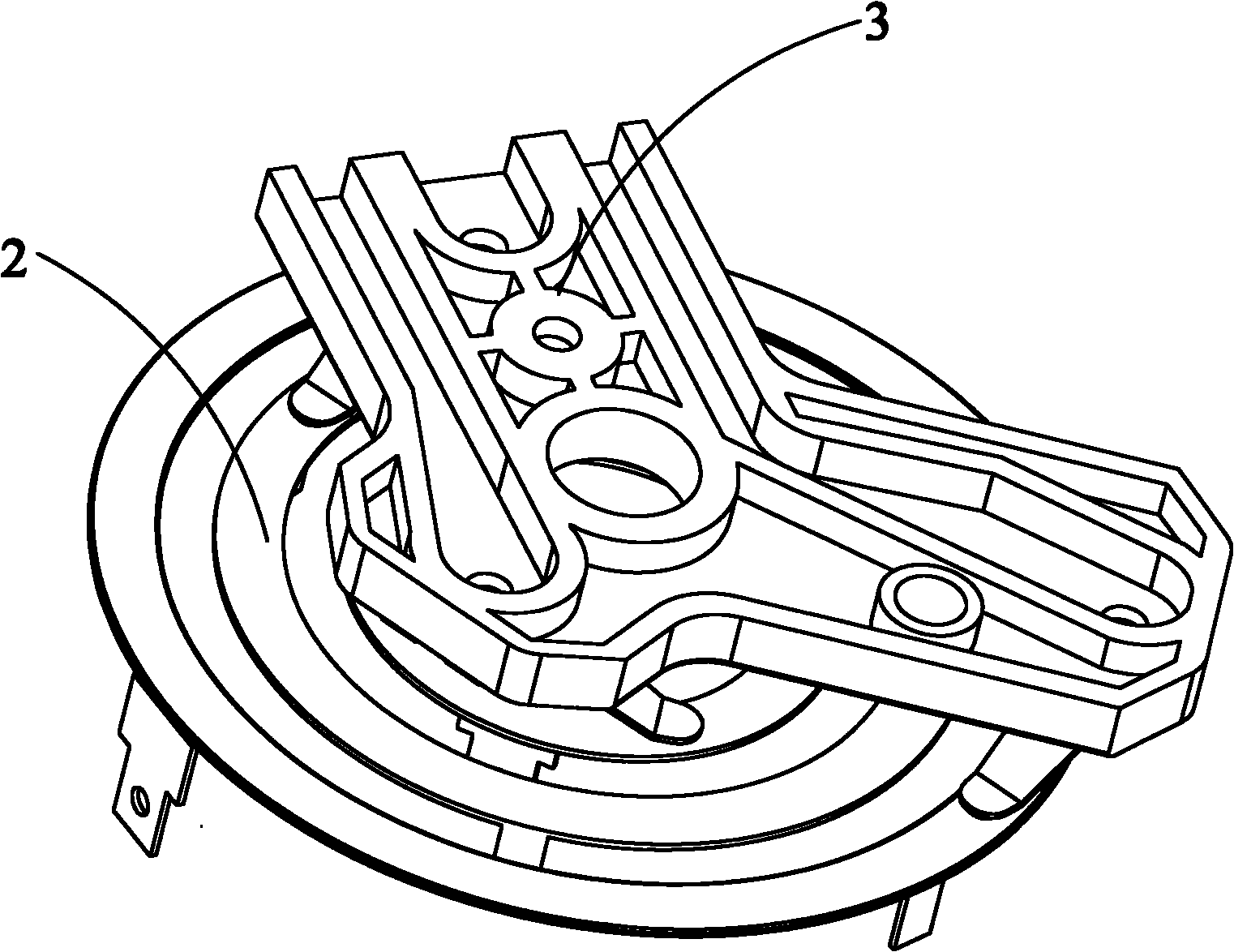

[0015] Please also refer to Figure 5 As shown, the track module 2 includes first, second, and third conductive tracks 21, 22, and 23 formed in a circle by a plurality of concentric rings, and a track module fixing part 24. The track module 2 It is fixed on the runner by the fixing part 24 .

[0016] Please also refer to Figure 4 As shown, the terminal module 3 includes first, second, third conductive terminals 31, 32, 33 and a terminal fixing base 34. The terminal base 34 is roughly flat and includes first, second, third Terminal fixing parts 341, 342, 343, the first, second, third conductive terminals 31, 32, 33 are respectively fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com