Stacked crimping type power module and manufacturing method thereof

A technology of power modules and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as large stray inductance, low blocking voltage of power chips, and poor heat dissipation efficiency, so as to improve heat dissipation ability, increase the withstand voltage value, and improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

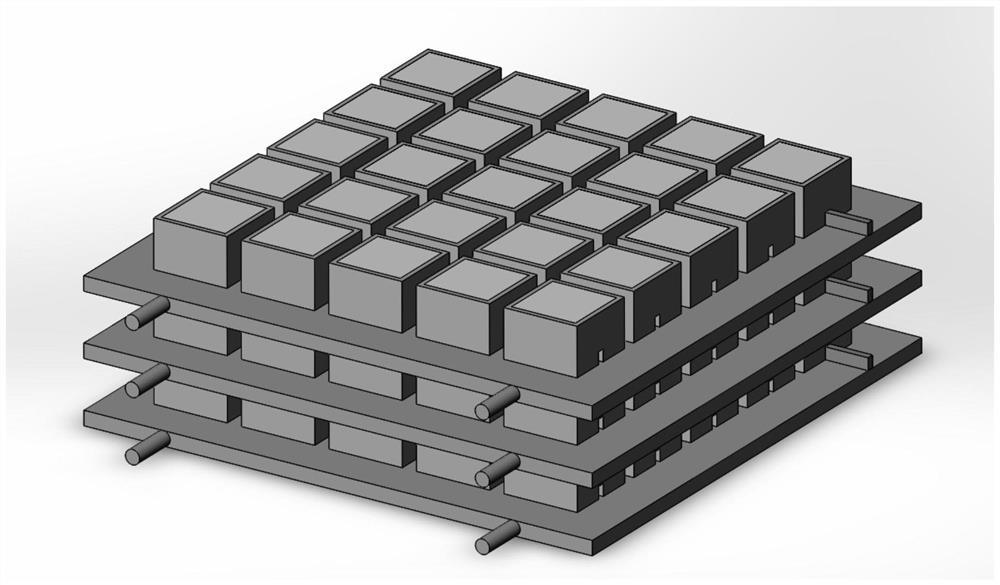

[0040] This embodiment provides a stacked crimping power module and its manufacturing method, such as Figure 1-8 shown.

[0041] Stacked press-fit power modules such as figure 1 As shown, there are at least two layers of stacked prefabricated parts, and the prefabricated parts are connected by crimping.

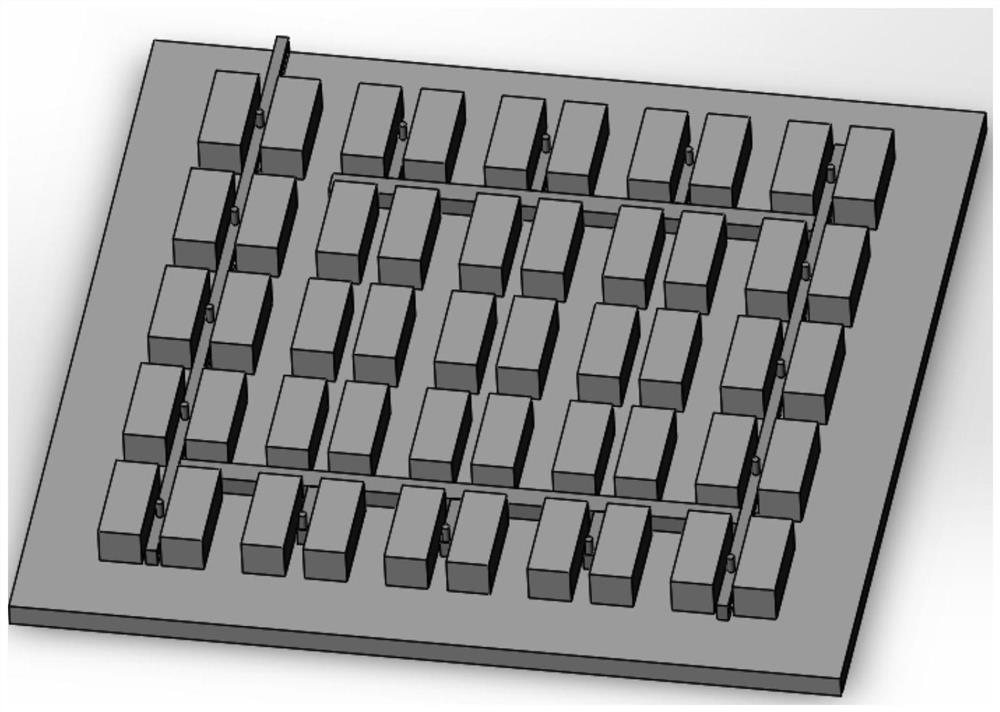

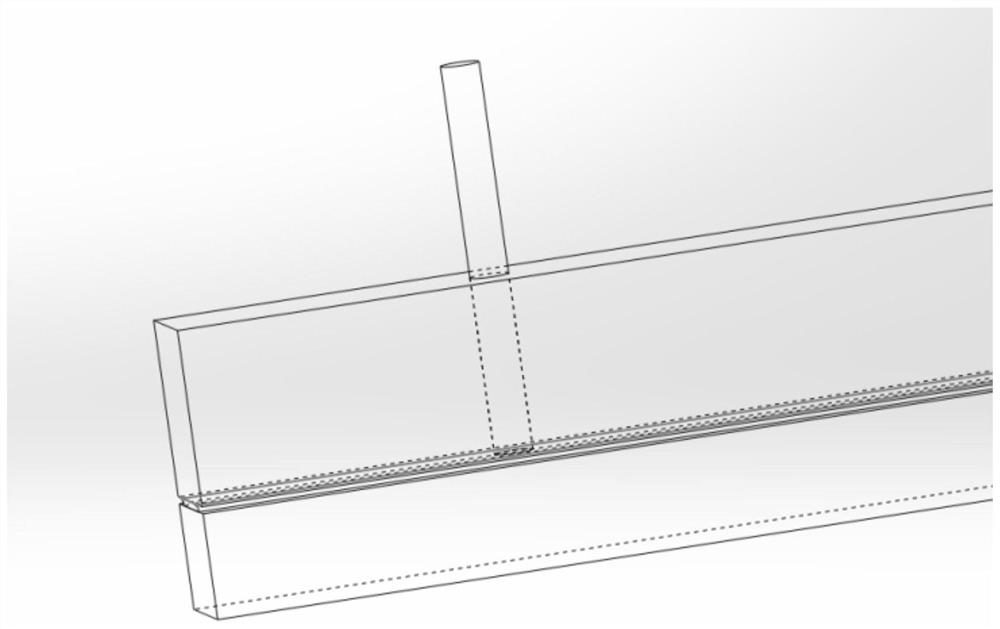

[0042] The prefabricated part includes a first metal base plate, and at least one boss for placing chips is engraved on the first metal base plate, and at least one gap area between the bosses; the gap between the bosses of the first metal At least one first metal strip is arranged in the area, and the metal strip is used for positioning grid pogo pins; a plurality of channels are arranged in the first metal floor, and the channels are used for transmitting liquid or gas materials for cooling.

[0043] The metal strip includes two and clamped up and down and the middle one; the metal strip is provided with at least one spring thimble, and the spring thimble penetrates the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com