Preparation method of super junction power device

A technology of power devices and super junctions, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of limited dopant concentration, limited etching depth and oxide film thickness, and electronic unevenness to achieve durability The effect of high voltage value, protection against damage, and low on-resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

[0051] Such as Figure 1 to Figure 10 As shown, the present invention discloses a preparation method of a super junction power device, which comprises the following steps:

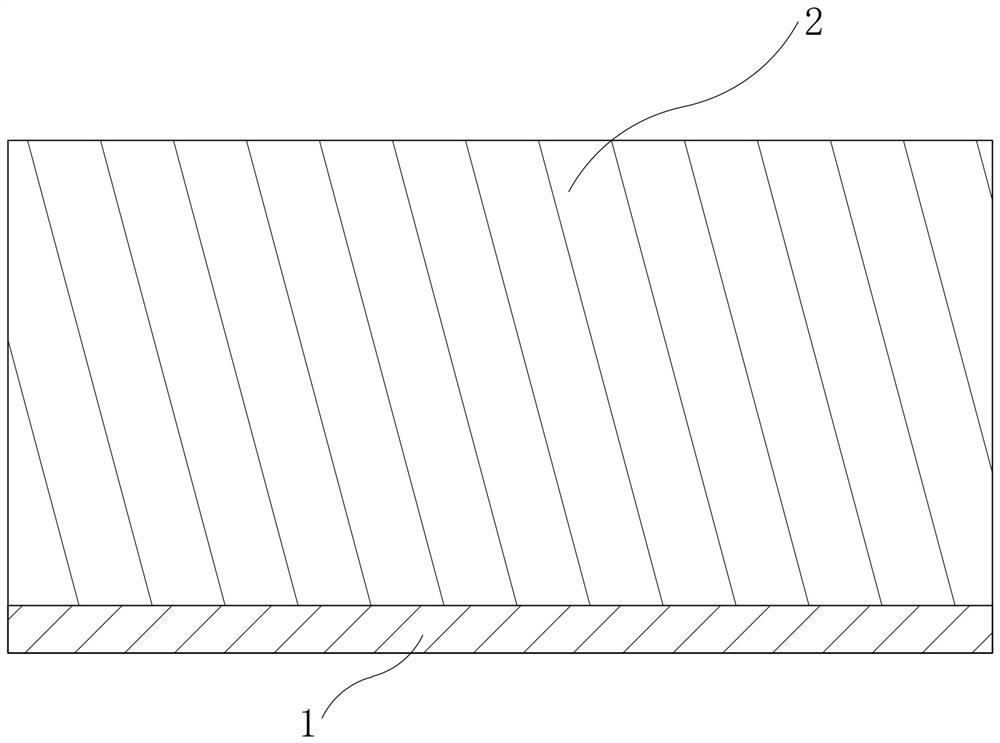

[0052] Step 1: Provide a semiconductor substrate 1 with a high doping concentration and an N-type conductivity type, and form a first epitaxial layer 2 with an N-type conductivity type on the front surface of the N-type semiconductor substrate 1;

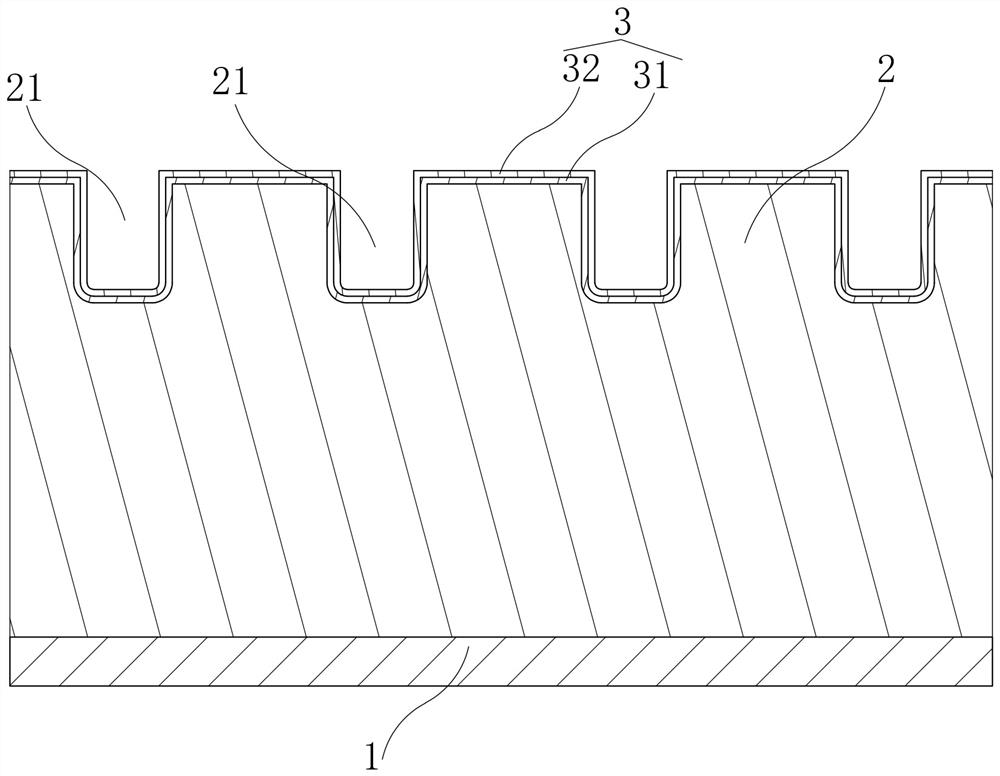

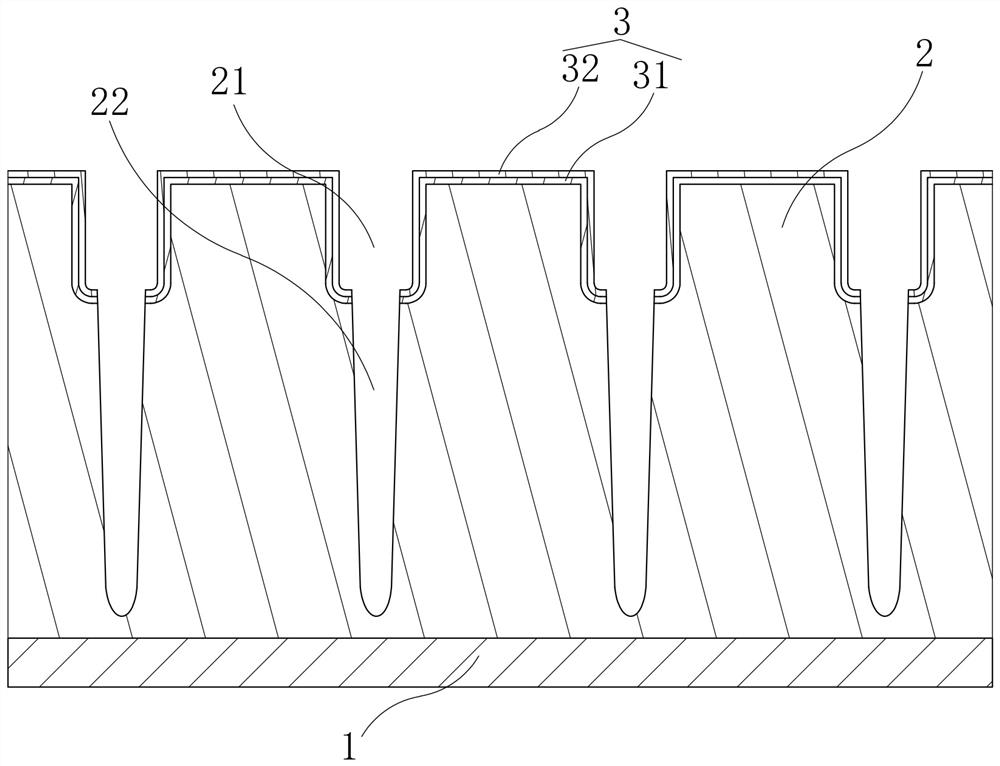

[0053] Step 2: Etch the front side of the first epitaxial layer 2 to form several gate trenches 21, and grow a protective layer 3 on the first epitaxial layer 2, the protective layer 3 covers the top surface of the first epitaxial layer 2 and each gate Pole trench 21; the protective layer 3 may include a basic protective layer 31 and a passivation layer 32 grown sequentially, and the basic prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com