Permanent magnet switched reluctance motor employing distributed winding

A distributed winding and permanent magnet switch technology, applied in the direction of electrical components, electromechanical devices, magnetic circuit static parts, etc., can solve the problems of low utilization rate of windings and low power density of motors, so as to improve utilization rate and torque Output capacity and power density, the effect of promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

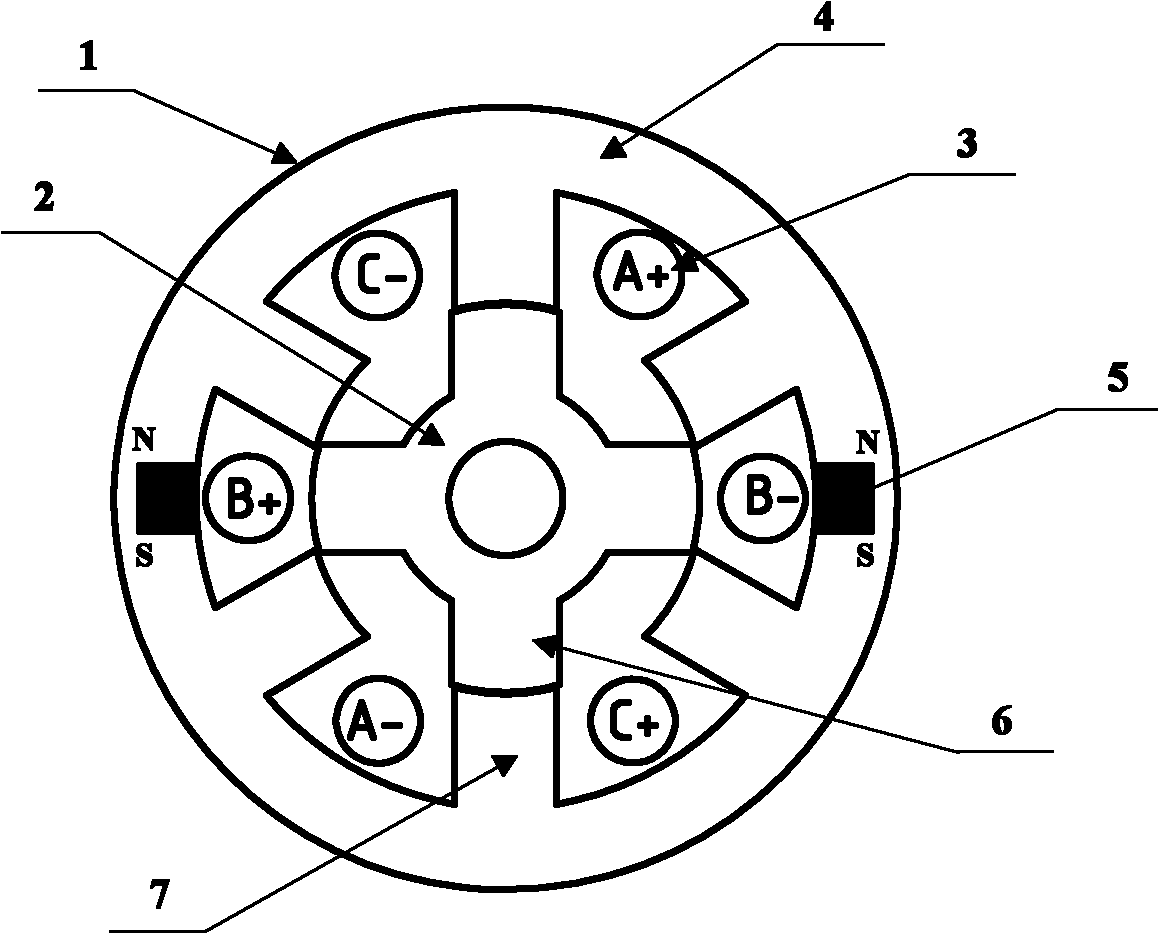

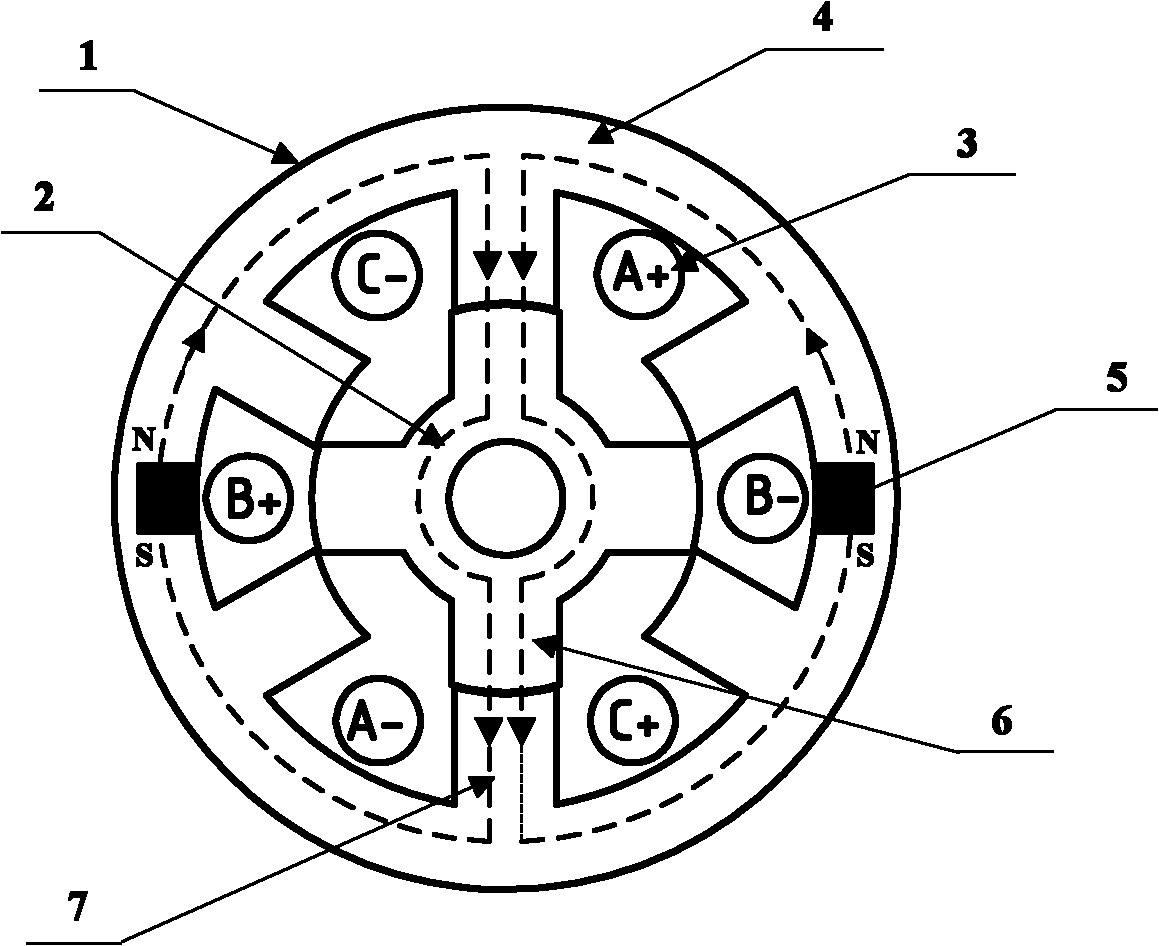

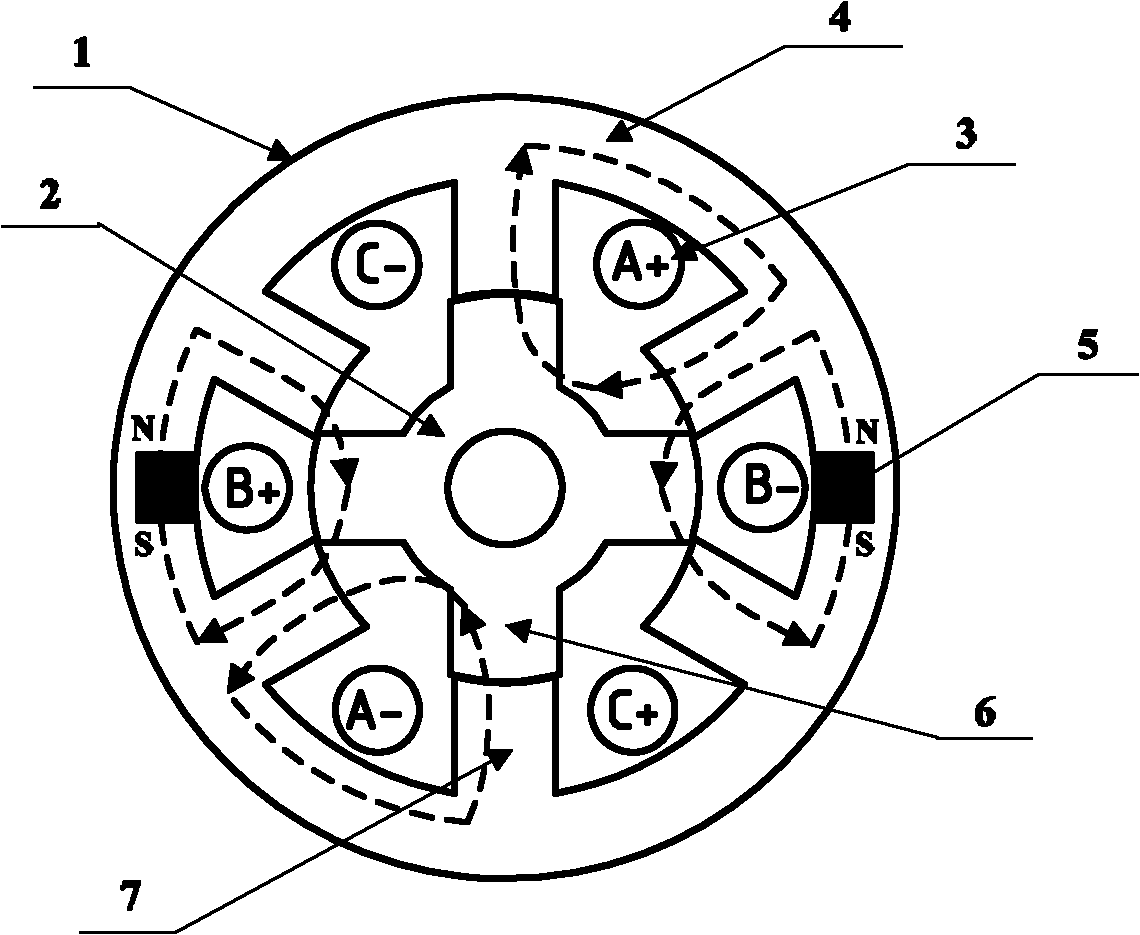

[0023] figure 1 Shown is a schematic structural diagram of a permanent magnet switched reluctance motor using distributed windings in the present invention. The motor includes a stator 1 and a rotor 2 sleeved inside the stator. Both the stator 1 and the rotor 2 are ring-shaped salient pole structures, and the inner ring of the stator 1 There are evenly distributed stator teeth 7 on the surface, and evenly distributed rotor teeth 6 on the outer ring surface of the rotor 2. There is a gap between the mutually nested stator core 4 and the rotor core 2, and the permanent magnet 5 is embedded in the stator core 4. The yoke, wherein: the stator 1 is wound with a three-phase armature winding 3 composed of a distributed structure, and there is only one winding coil between the slots of the adjacent stator teeth 7, and the coils that cross two stator slots are connected to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com