Durable magnesium oxychloride cement and process therefor

A technology of magnesium oxychloride cement and magnesium chloride, which is applied in the direction of sustainable waste treatment, solid waste management, and climate sustainability, and can solve the problems of reduced strength and dimensional stability of MOC materials, and affecting the stability of binder phase F5, etc. Achieve the effect of low heat shrinkage, high homogeneity and high bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

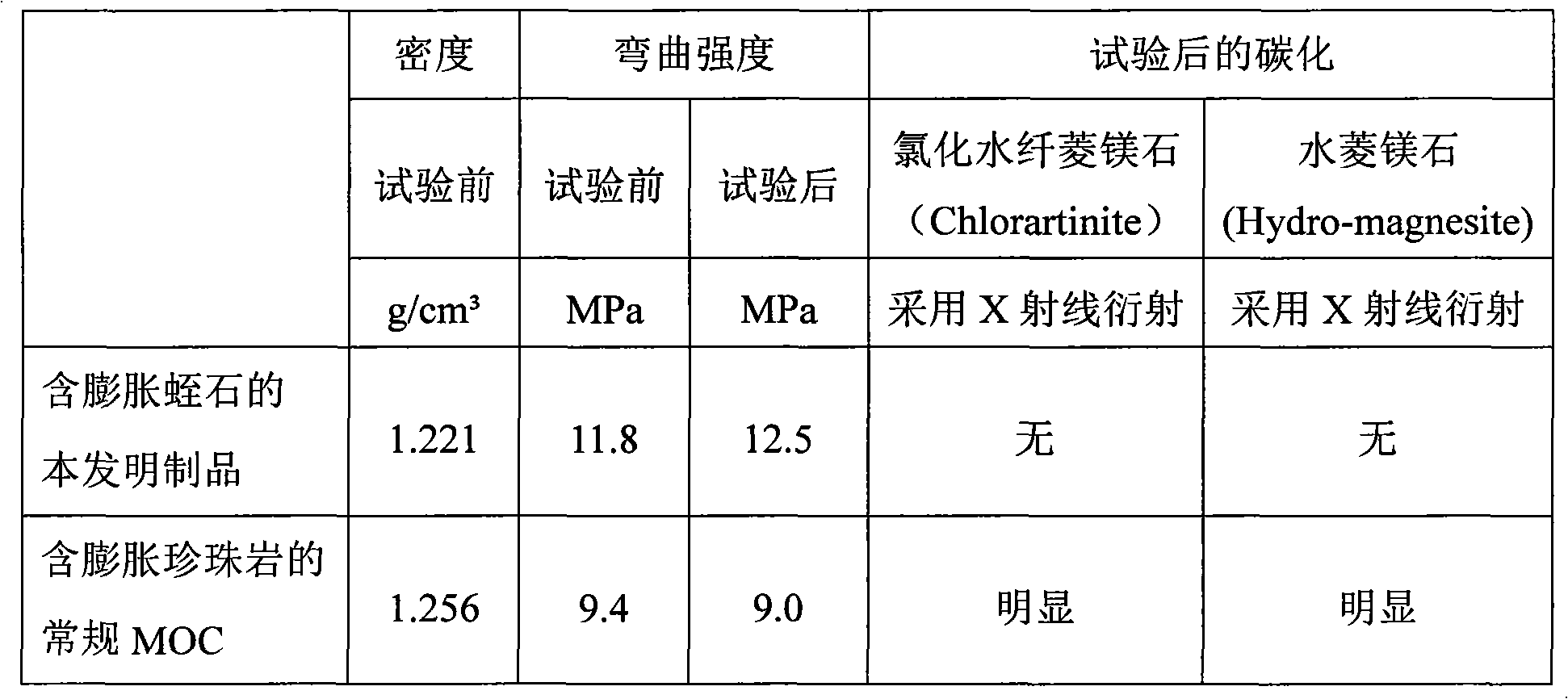

Embodiment 1

[0065] A MOC composition is obtained by mixing caustic magnesia with particle size of 100 mesh, MgCl 2 It is prepared by aqueous solution, phosphoric acid and expanded vermiculite, and its mixed formula is MgO 32.2%, MgCl 2 12.6%, P 2 o 5 0.3%, H 2 O 41.0% and expanded vermiculite 13.9%.

[0066] On the other hand, a conventional MOC composition was prepared in the same manner as above, except that the expanded vermiculite was replaced by an equivalent amount of expanded perlite having a particle size distribution equivalent to that of the expanded vermiculite.

[0067] After mixing with a planetary mixer for 10 minutes, the resulting mixture was cast in molds. Cured at 20°C for 1 day under covered conditions, after which the samples were demoulded and placed in the open air at 20°C for 7 days.

[0068] The accelerated aging test of the sample was carried out in the artificial climate box, and the sample was kept at 40°C, 95% relative humidity and 100% CO 2 exposed to ...

Embodiment 2

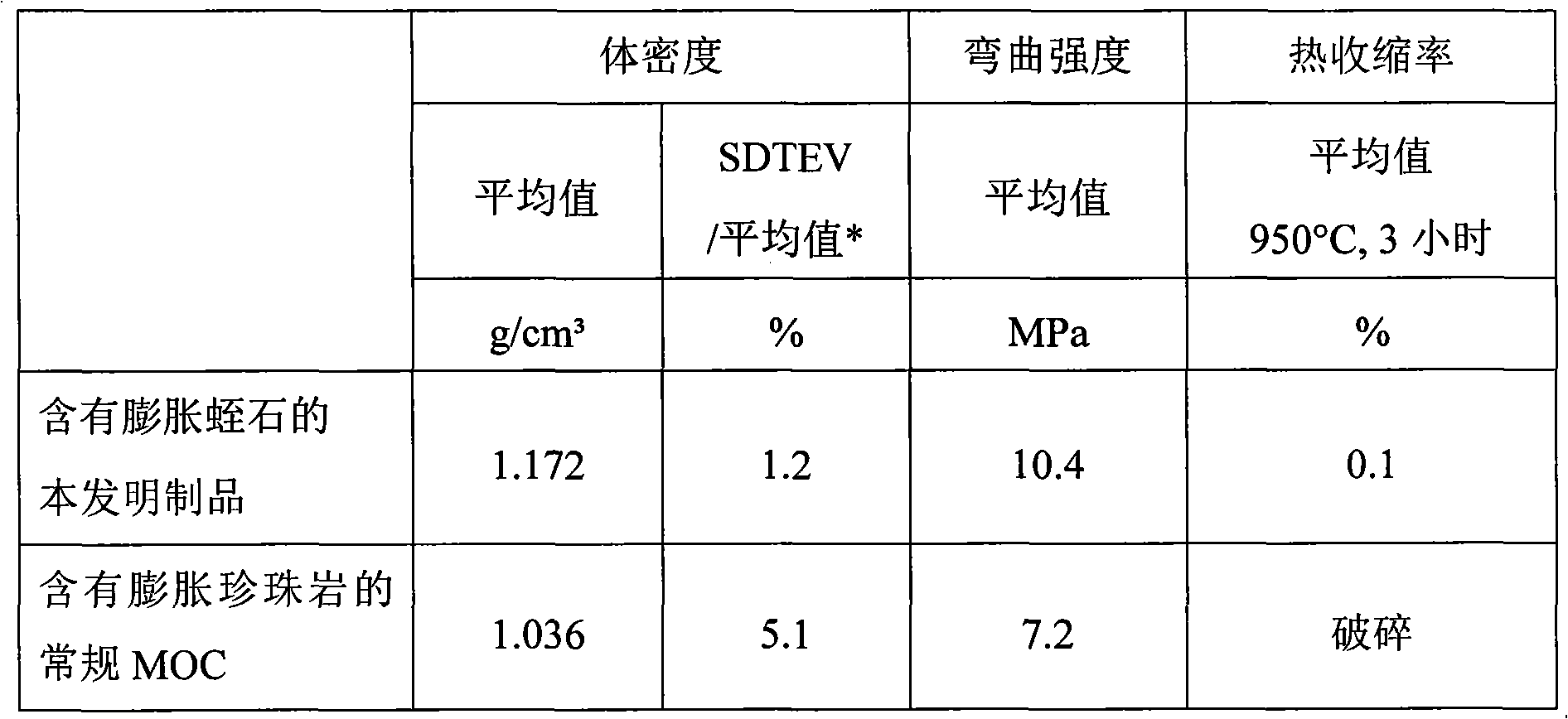

[0073] A kind of MOC composition according to the present invention is to be 100 order caustic magnesia, MgCl by mixing particle size 2 It is prepared by aqueous solution, phosphoric acid and expanded vermiculite, and its mixed formula is MgO 28.8%, MgCl 2 13.3%, P 2 o 5 0.4%, H 2 O 43.4% and expanded vermiculite 14.1%.

[0074] The curing conditions were the same as described in Example 1.

[0075]A sample of 400mm×400mm×15mm was made. After curing, 10 smaller samples of 400 mm x 40 mm x 15 mm were cut and the homogeneity of the mixture was tested for flexural strength, density and their standard deviation. The test results are listed in Table 2.

[0076] Table 2. Test results

[0077]

[0078] *SDTEV = standard deviation

[0079] The sample of the present invention has high strength and mixing uniformity, and its 1.2% bulk density has a very small difference in measured values. The thermal shrinkage at 950°C is very low.

[0080] In contrast, the samples of th...

Embodiment 3

[0082] A MOC board with improved properties according to the present invention is obtained by mixing caustic magnesia, MgCl with a particle size of 100 mesh 2 It is prepared by aqueous solution, phosphoric acid and expanded vermiculite, and its mixed formula is MgO 25.9%, MgCl 2 12.0%, P 2 o 5 0.3%, H 2 O 39.1%, expanded vermiculite 12.7% and CaCO 3 (Calcite) 10.0%.

[0083] On the other hand, a conventional MOC composition was prepared in the same manner as above except that expanded vermiculite was replaced by an equal amount of expanded perlite having a particle size distribution equivalent to that of expanded vermiculite.

[0084] The curing and drying procedure for the samples was as described in Example 2.

[0085] Conduct a fire test. The hot side of the plate is exposed to fire and heated up according to ISO 834; while the cold side is exposed to air at 20°C.

[0086] When the fire test was carried out for 20 minutes and the fire temperature was 780°C, at a di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap