Transplanting mechanism of double-shaft bevel gear drive tilting wide-and-narrow row rice transplanter

A gear transmission and bevel gear technology, which is applied in transmission devices, belts/chains/gears, transplanting machinery, etc., can solve the problems of easy chain breakage, affecting the popularization and application of new agronomic methods for transplanting rice seedlings in width and narrow rows, and large vibration of chain transmission. To achieve the effect of low vibration, good quality of work, and few work failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

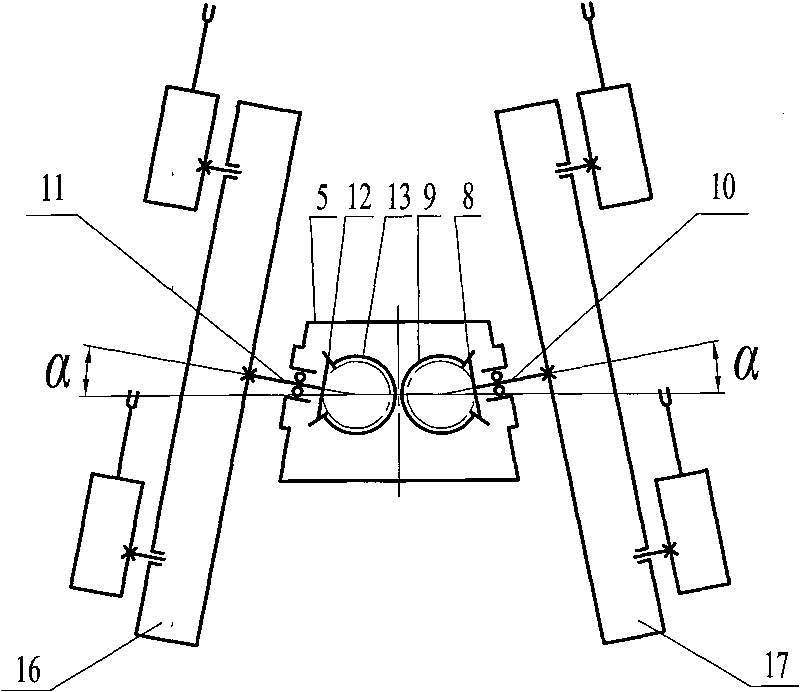

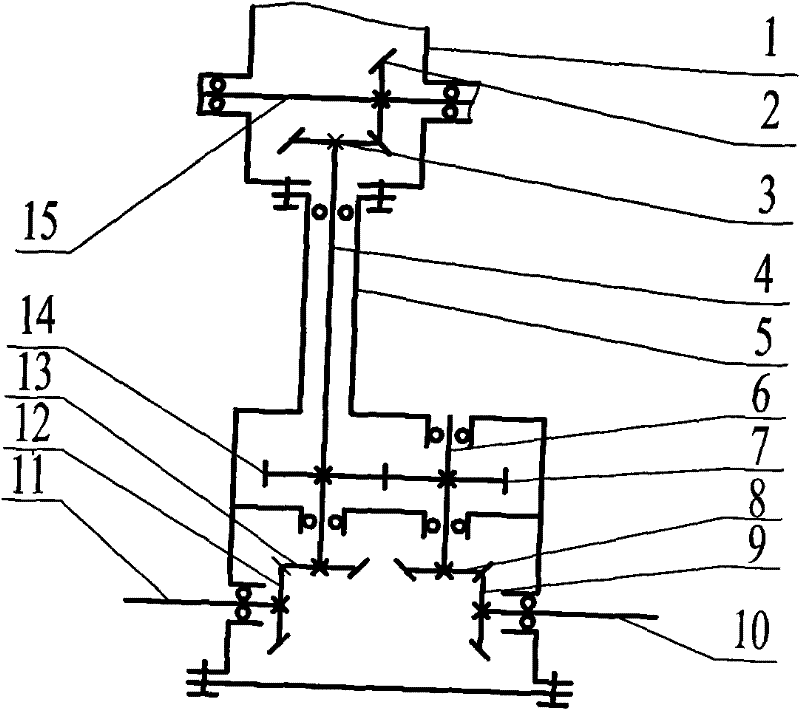

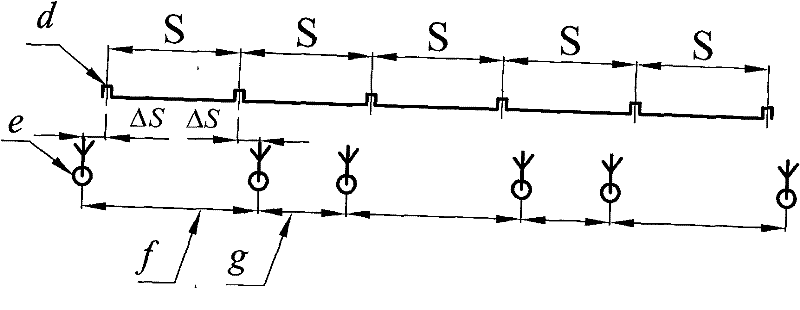

[0011] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. Such as figure 1 , figure 2 shown. The splitting mechanism of the double-axis bevel gear transmission inclined wide and narrow row rice transplanter includes a left splitting mechanism 16 and a right splitting mechanism 17, the moving box body 1 and the transmission box casing 5 are fixedly integrated, and the first bevel gear 2 is fixedly installed The power input shaft 15 is assembled in the moving box body 1, and the main transmission shaft 4 and the power input shaft 15 of the second bevel gear 3, the driving cylindrical gear 14 and the third bevel gear 13 are installed vertically in the moving box. In the box body 1 and the transmission box casing 5, the second bevel gear 3 is located in the shift box casing 1 and meshed with the first bevel gear 2, and the driving cylindrical gear 14 and the third bevel gear 13 are located in the transmission bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com