Direct drive type hoist with boosting caliper brake

A caliper brake and booster technology, which is applied to lifts, lifting equipment in mines, electromechanical devices, etc., can solve problems such as easy rollover of the car, difficulty in ensuring the working air gap of the motor, and difficulty in braking the hoist. Achieve the effect of reducing the size of the installation base, reliable operation, and reducing the size of the cross section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

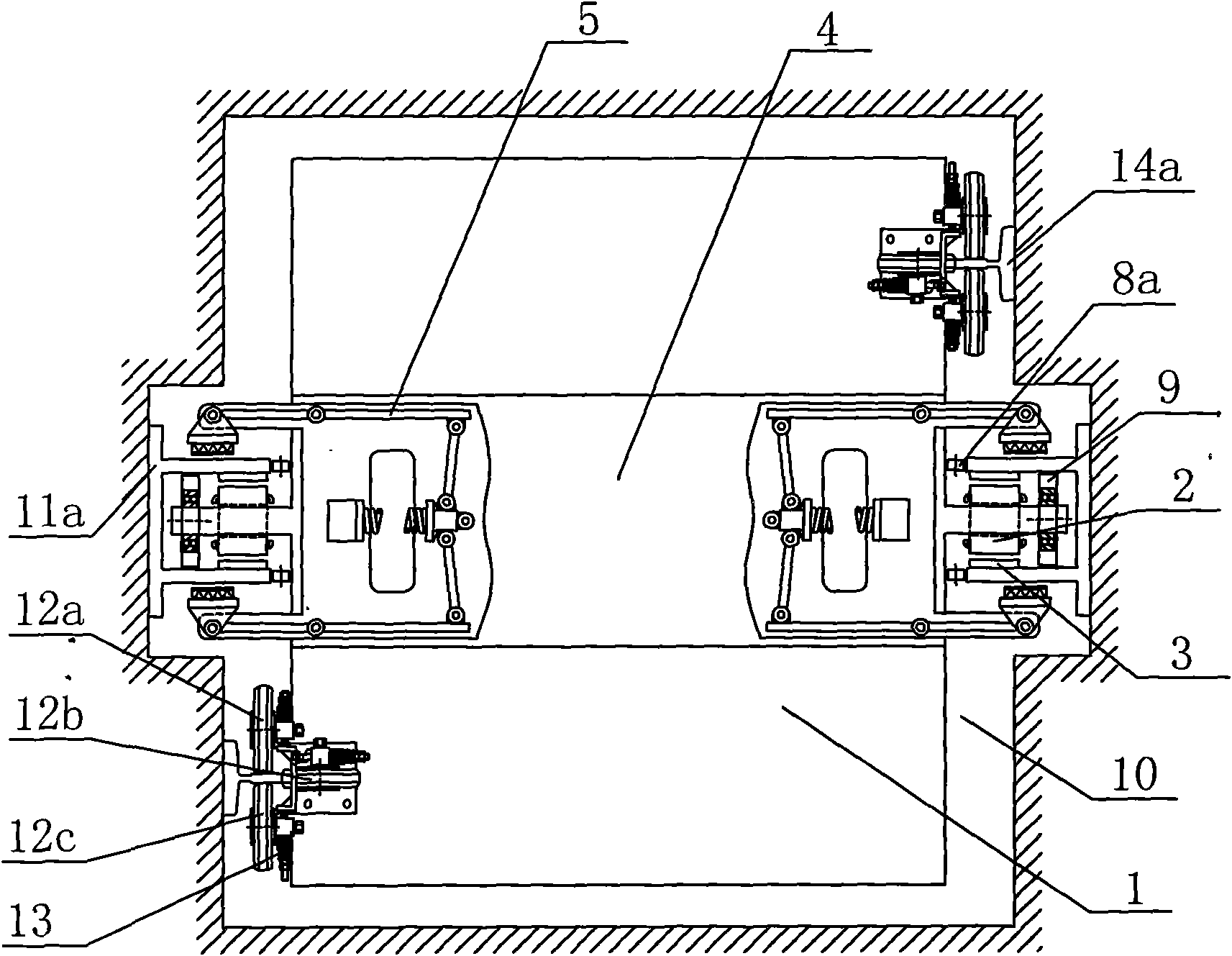

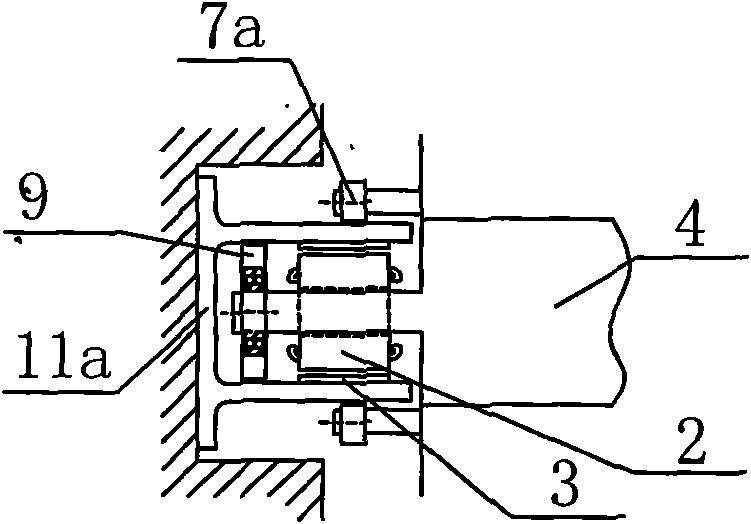

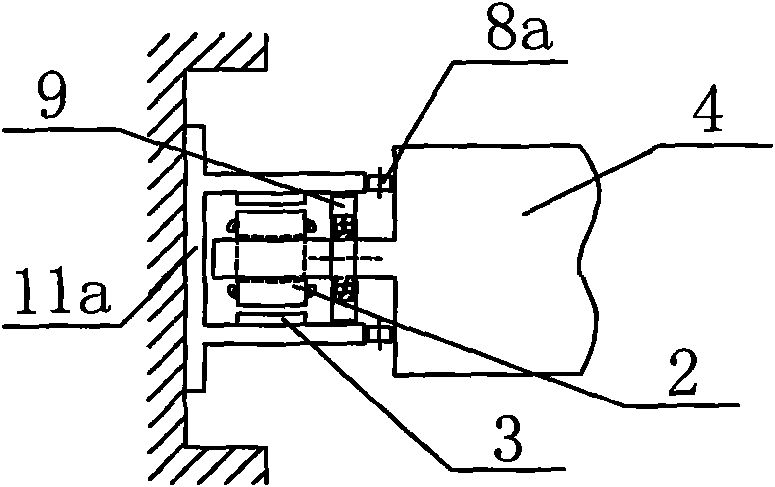

[0045] like figure 1 9 options for direct drive hoists with booster caliper brakes are shown, figure 1 (A) is the overall sectional schematic diagram of described direct-drive hoist, figure 1 (B~I) are the direct drive hoist and figure 1 (A) Partial cross-sectional schematic diagrams of different schemes adopted on the motor working air gap multi-wheel positioning mechanism.

[0046] Below to figure 1 (A) is taken as an example to explain in detail.

[0047] like figure 1 As shown in (A), a direct-drive hoist with a booster caliper brake includes a vertical shaft 10, a car 1, a booster caliper brake 5, a car frame 4, and a permanent magnet linear motor for lifting , safety gear, and positioning mechanism, and provide the power supply of the motor mover, car 1, and booster caliper brake 5 through the power supply cable fixed on the inner wall of the vertical shaft 10, the power supply rail contact or non-contact mode.

[0048] The driving source of the direct drive hoist ...

Embodiment 2

[0063] like image 3 As shown in the direct-drive hoist with booster caliper brake, the positioning mechanism is only provided with a motor working air gap multi-wheel positioning mechanism. Other structures are the same as those in Embodiment 1 figure 1 (A).

[0064] In addition, various motor working air gap multi-wheel alignment mechanisms described in Embodiment 1, such as figure 1 (B~I), be applicable to embodiment 2 equally.

Embodiment 3

[0066] like Figure 4 As shown, a direct-drive hoist with a booster caliper brake, the booster caliper brake 5 is installed on the diagonal position of the car 1 or the side extension beam of the car frame, and acts on the braking T-type Track I 14b. Other structures are the same as those in Embodiment 1 figure 1 (A).

[0067] In addition, various motor working air gap multi-wheel positioning mechanisms described in Embodiment 1, such as figure 1 (B~I), be applicable to embodiment 3 equally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com