Computerized flat knitting machine control system

A computerized flat knitting machine control and motor driver technology, applied in textiles and papermaking, weft knitting, knitting and other directions, can solve the problems of low production efficiency and low reliability, and achieve high efficiency, reliability and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

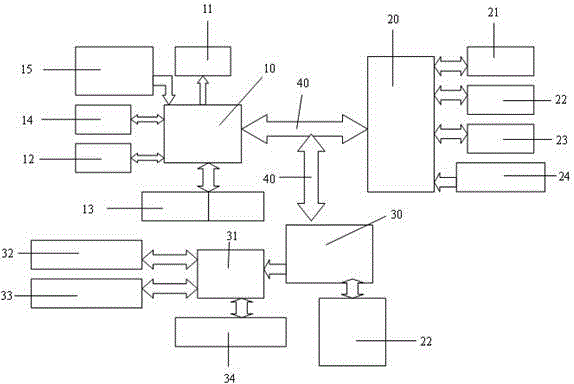

[0020] see figure 1 , The computerized flat knitting machine control system of the present invention includes an industrial computer 10 , a head main control part (DSP controller) 20 and a machine tool main control part (ARM controller) 30 . The industrial computer 10 , the machine head main control part 20 , and the machine tool main control part 30 exchange data through a CAN (Controller Area Network) bus 40 .

[0021] The industrial computer 10 is connected with a display screen (LCD) 11, a control panel (not shown in the figure), an Ethernet (LAN) interface 12, a U disk 13, a touch screen (not shown in the figure), an RS485 interface (not shown in the figure), USB interface 14, PS2 / Keyboard 15, and flower-shaped interpreter (not show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com