Steel roof capable of preserving heat, resisting water and bearing person

A technology of steel roofing and roof panels, applied in the direction of roof cladding, building roofs, etc., can solve the problems of no automatic absorption of thermal expansion and contraction, no access to people, poor thermal insulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

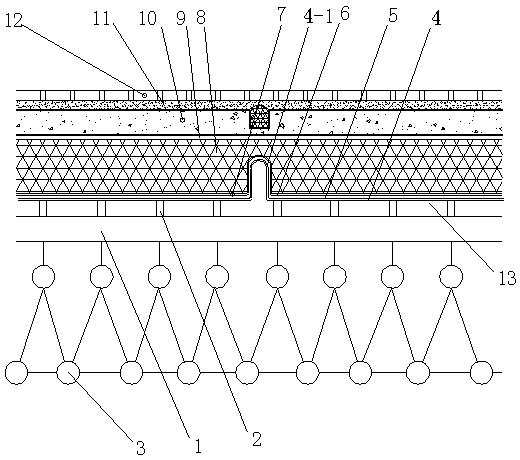

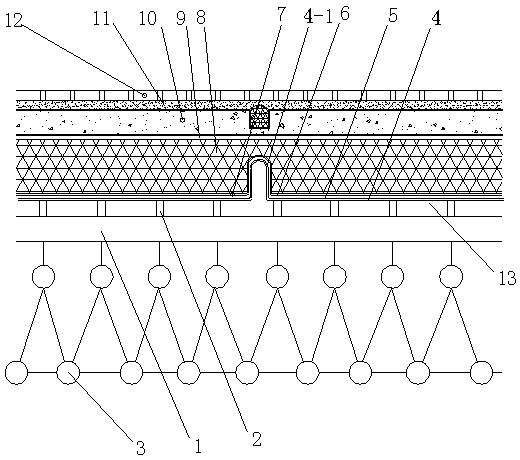

[0009] Such as figure 1 As shown, the present invention fixedly connects the I-shaped secondary beam 2 on the main beam 1, a steel structure grid 3 is arranged below the main beam 1, and a steel plate roof panel 4 with a thickness of 4 mm is fully welded on the secondary beam 2. The folded expansion joint section 4-1 is arranged on the steel plate roof panel 4.

[0010] On the upper surface of the steel plate roof panel 4, set up a cement ceramsite slope layer 5, a cement mortar leveling layer 6, a main waterproof layer 7, a polystyrene foam insulation layer 8, an outer waterproof layer 9, a fine stone concrete layer 10, and an adhesive layer 11 and facing floor tile layer 12. A fireproof coating 13 is provided on the lower surface of the steel plate roof panel 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com