Double-rotor two-stage enthalpy-increase compressor, air conditioner and heat pump water heater

A technology for heat pump water heaters and compressors, which is applied to compressors, compressors with reversible cycles, heat pumps, etc., can solve problems such as leakage friction loss, unstable performance, and large vibration of enthalpy-increasing compressors, so as to reduce leakage and mechanical Effects of frictional loss, improvement of overall performance, and improvement of heating capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

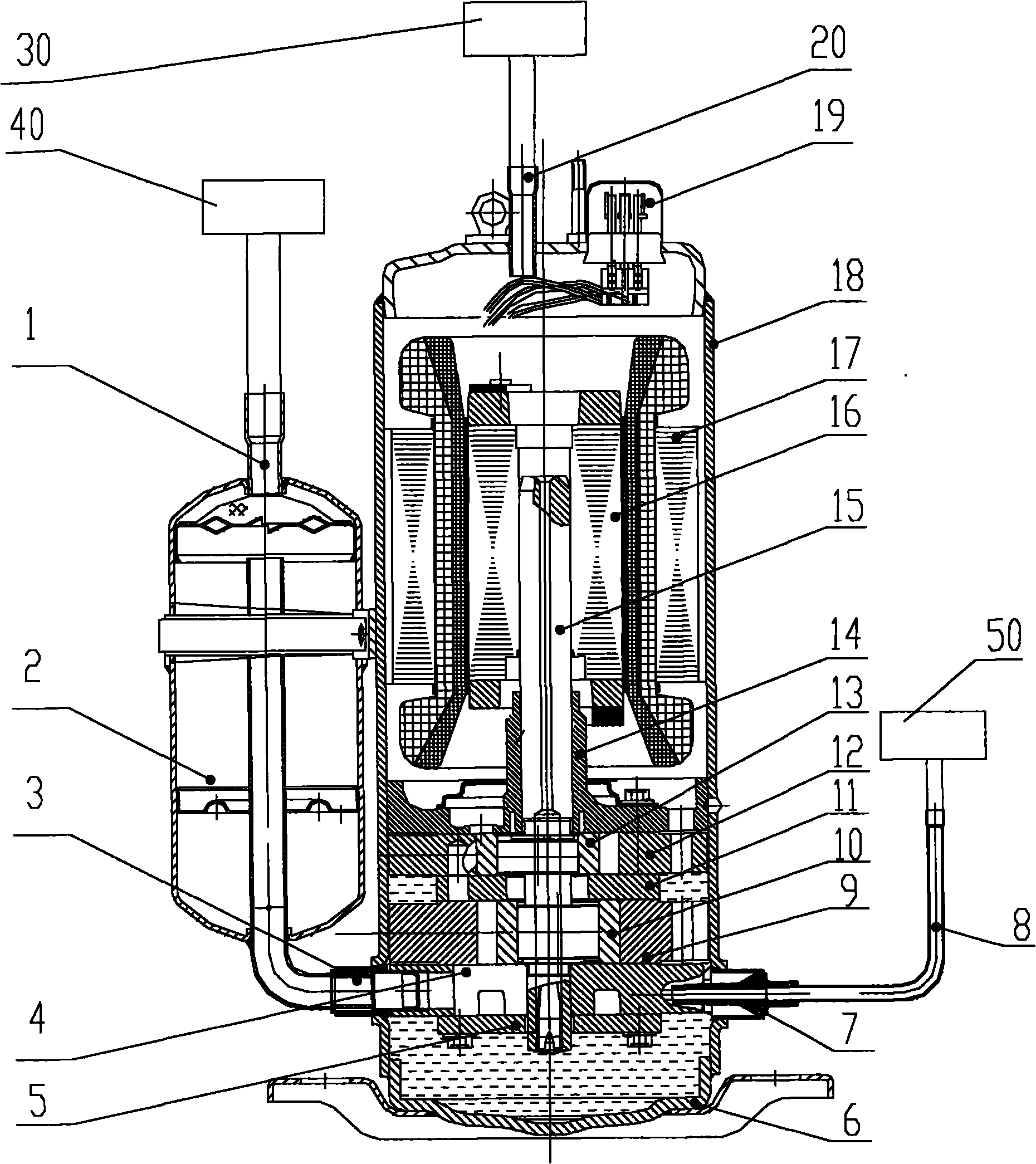

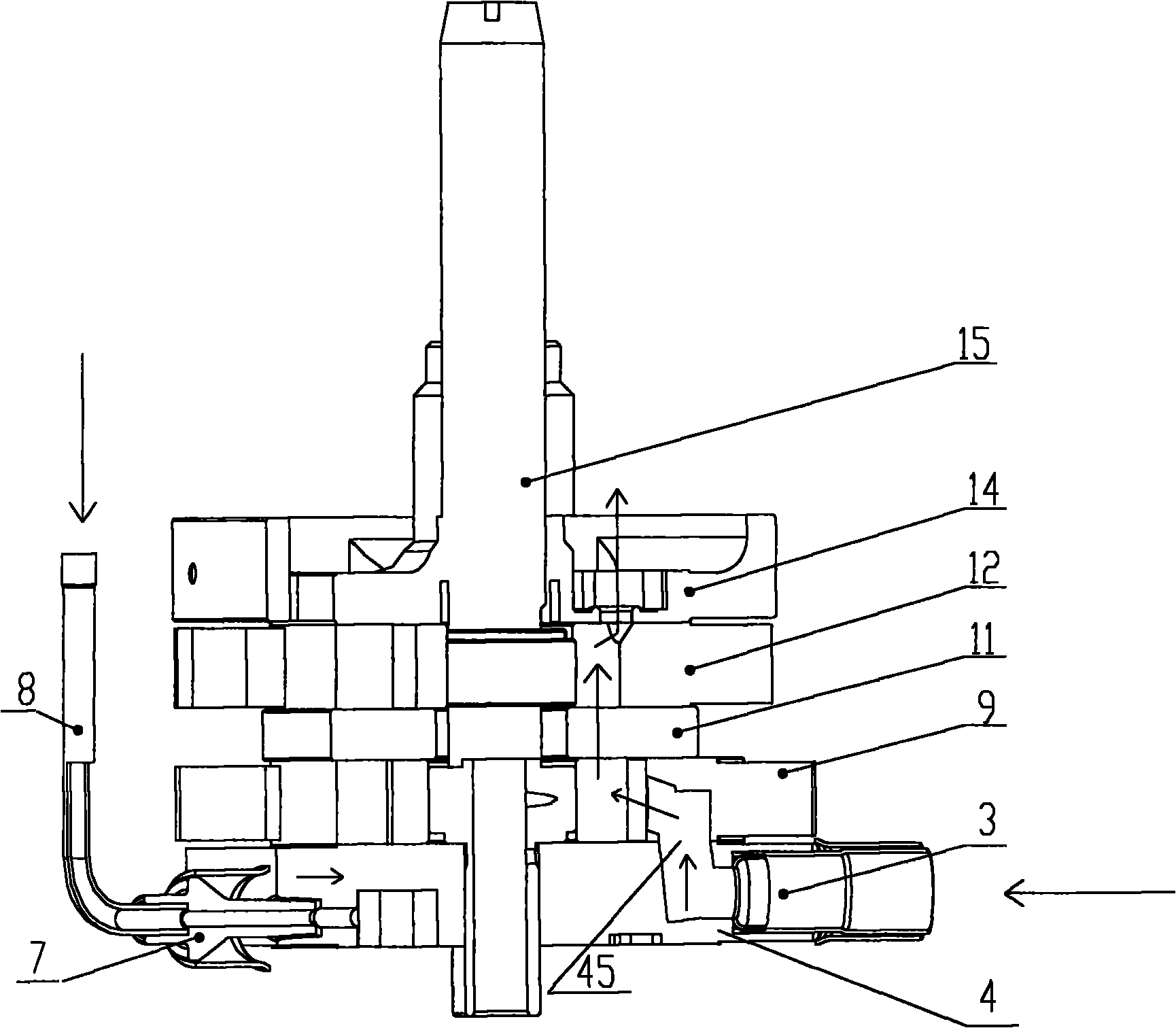

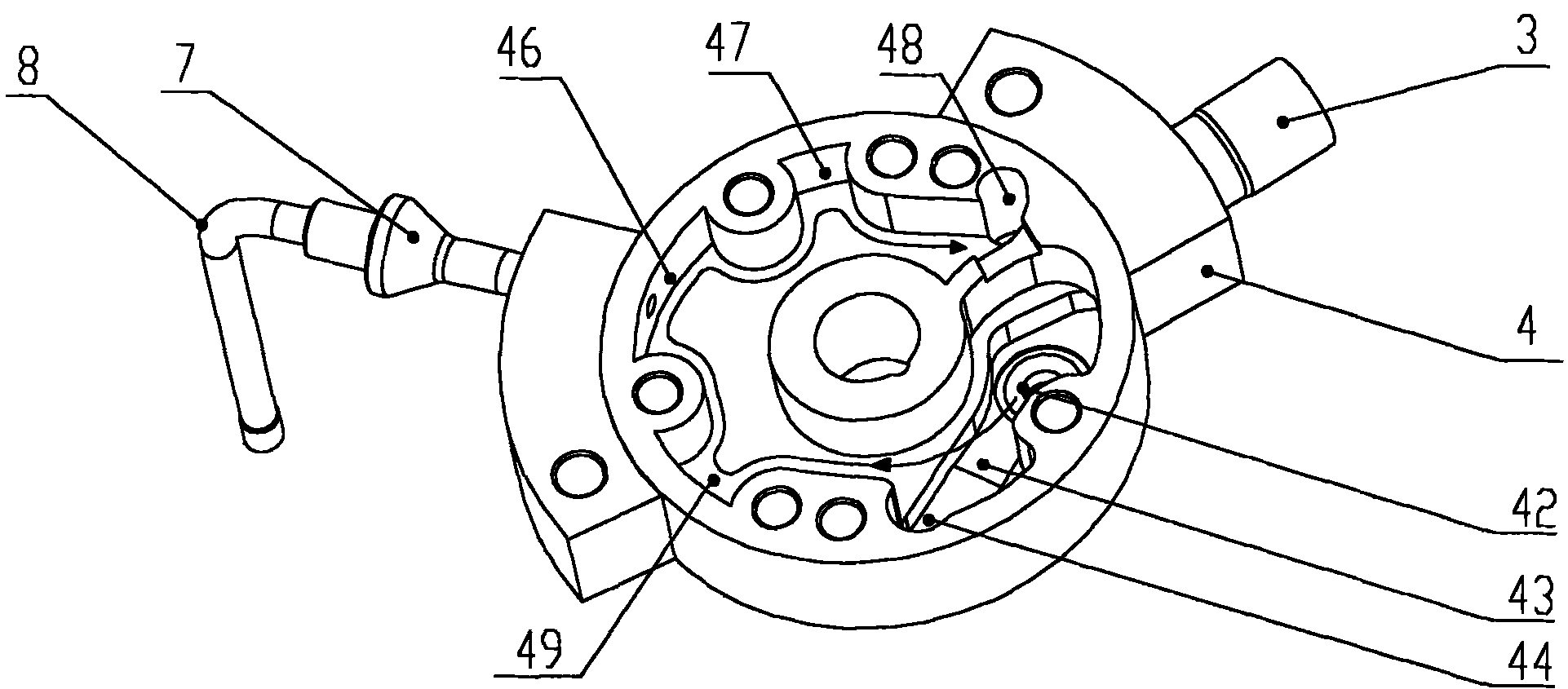

[0024] Figure 1 to Figure 3 Schematically shows the structure of the dual-rotor two-stage enthalpy-increasing compressor according to the embodiment of the present invention. As shown in the figure, the dual-rotor two-stage enthalpy-increasing compressor 18 according to the embodiment of the present invention includes: suction pipe 1, liquid separator 2, shell suction pipe 3, lower flange 4, lower cover plate 5, Compressor housing 6, enthalpy increasing tube 7, enthalpy increasing capillary tube 8, low pressure cylinder 9, lower roller 10, middle plate 11, high pressure cylinder 12, upper roller 13, upper flange 14, crankshaft 15, motor rotor 16, Motor stator 17, exhaust pipe 20.

[0025] The low-pressure cylinder 9 and the lower roller 10 inside are arranged above the lower flange 4 ; the lower cover plate 5 is arranged at the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com