Conductive coating structure for lighting device

A lighting device and conductive package technology, which is applied to lighting devices, components of lighting devices, lighting and heating equipment, etc., can solve problems such as poor conductive performance, inability to effectively improve speed, and affect the service life of lighting devices. Achieve the effect of improving yield and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

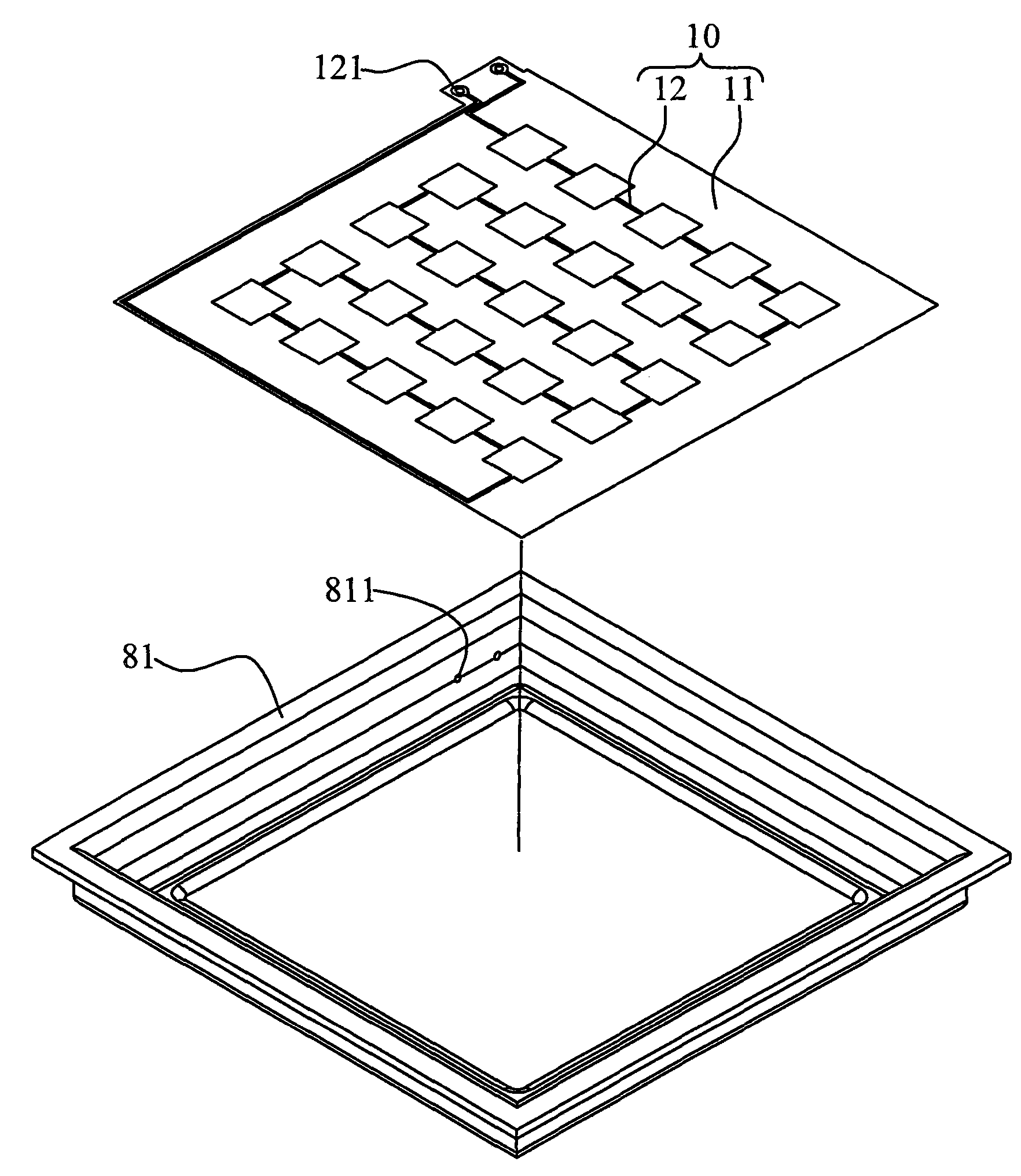

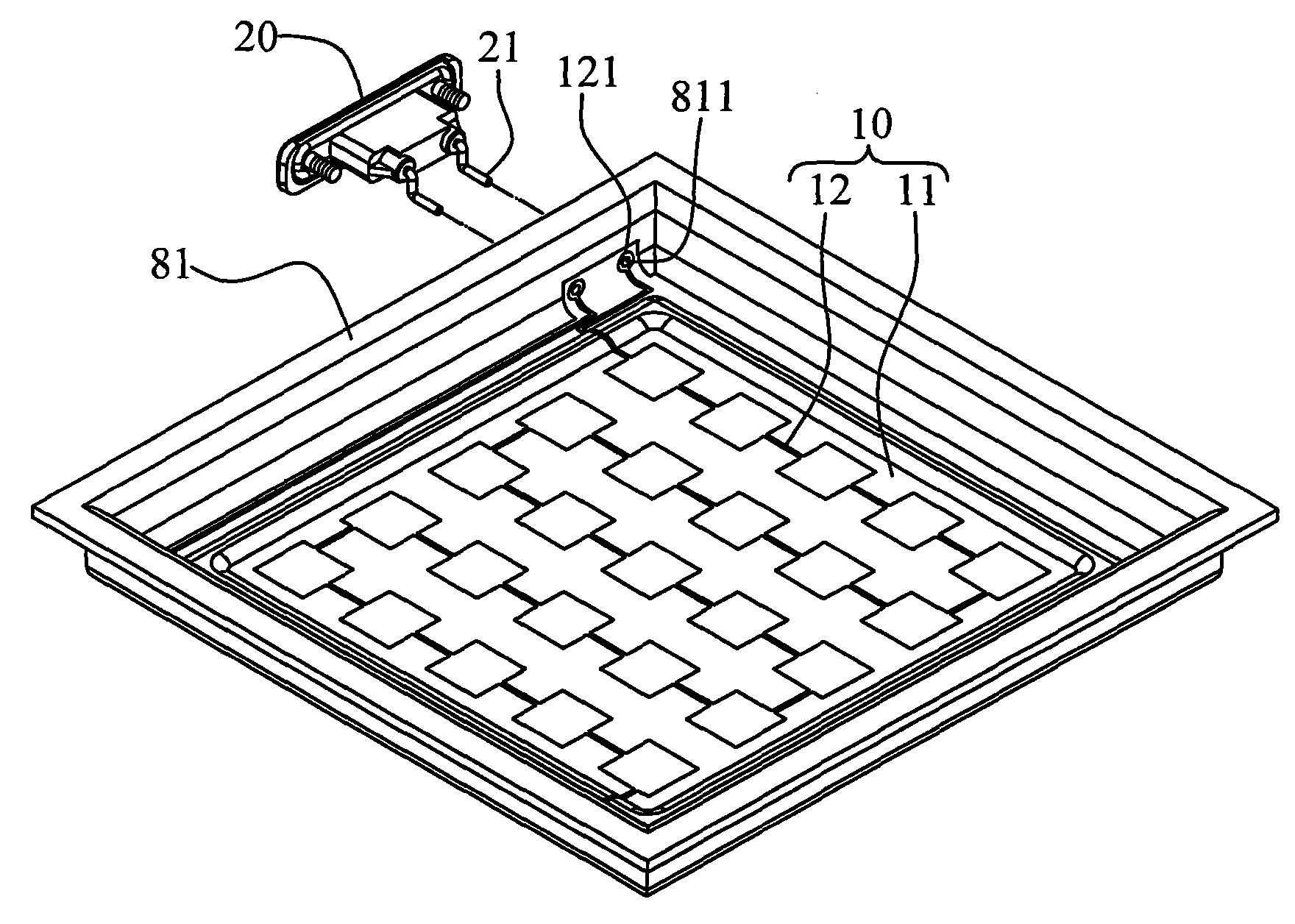

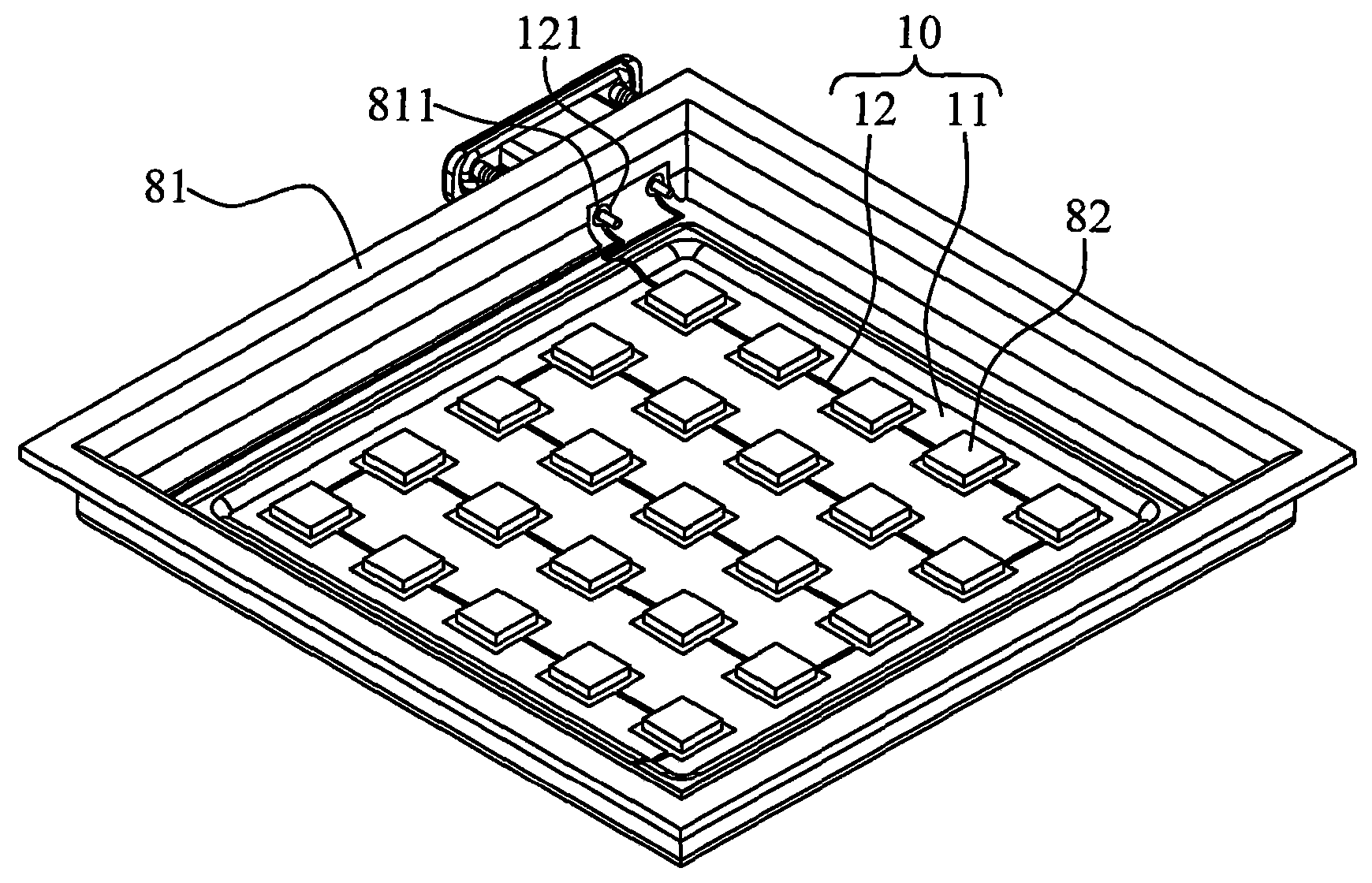

[0030] The detailed description and technical content of the present invention are described below with accompanying drawings, but the attached drawings are only for reference and description, and are not intended to limit the present invention.

[0031] Please refer to Figure 1 to Figure 4 As shown, the present invention provides a conductive coating structure of a lighting device. The lighting device 8 includes a metal socket 81 and a plurality of light-emitting components 82. The metal socket 81 in this embodiment is a box with an open end. The light-emitting The component 82 can be in the form of a bare LED or a lens-packaged LED. The conductive covering structure includes a conductive circuit 10 , an electrical connector 20 , a light-transmitting body 30 and a lampshade 40 .

[0032] The conductive circuit 10 is composed of an insulating layer 11 and a copper foil circuit layer 12 arranged above the insulating layer 11. The insulating layer 11 corresponds to the inner su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com