Hydrate formation kinetics simulation experiment device

A technology for simulating experimental equipment and hydrate generation, which is applied in the direction of material electrochemical variables, material resistance, etc., can solve the problems of difficult observation, complex nucleation process mechanism, etc., and achieves the effects of convenient operation, accurate testing and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

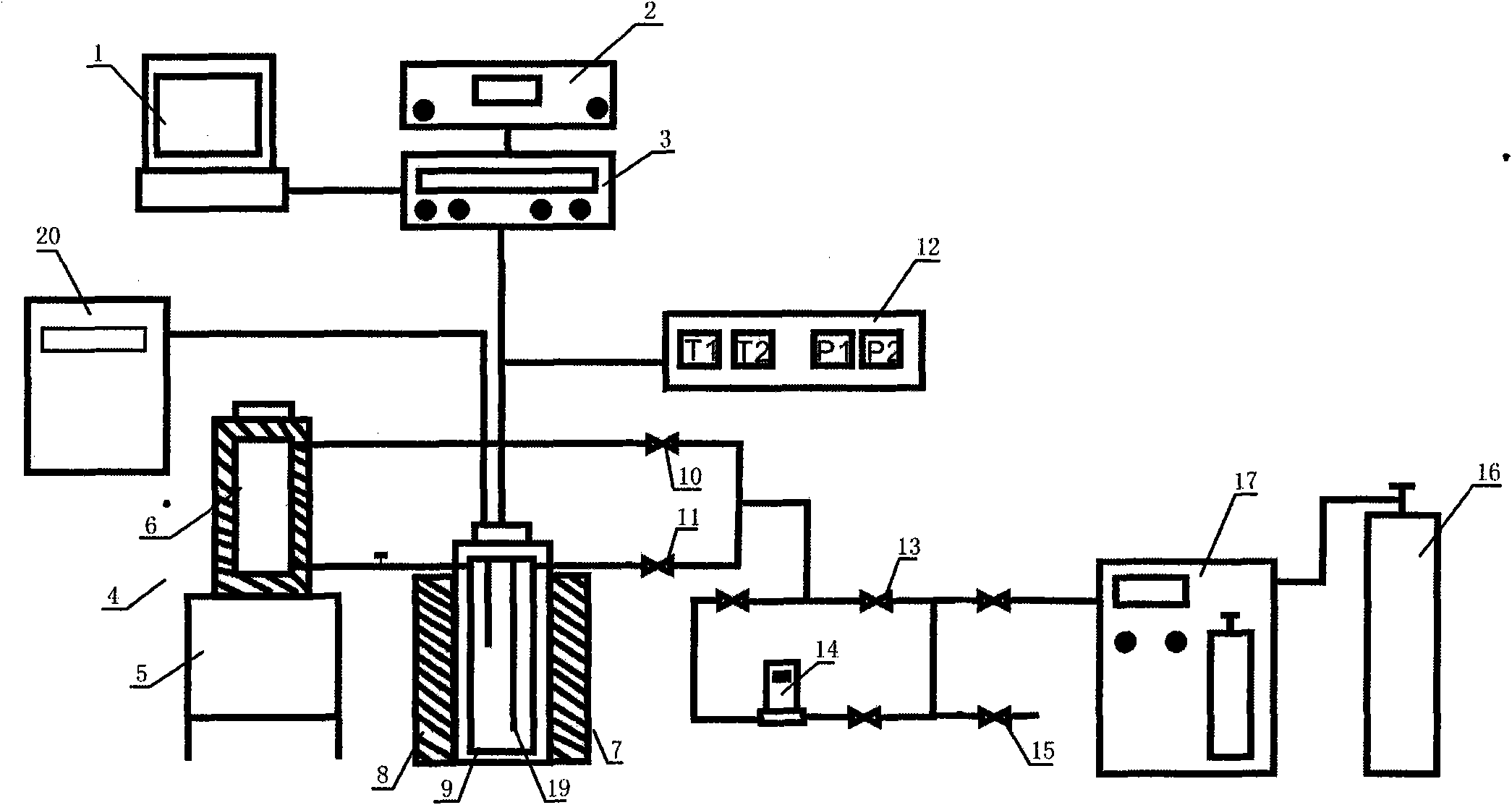

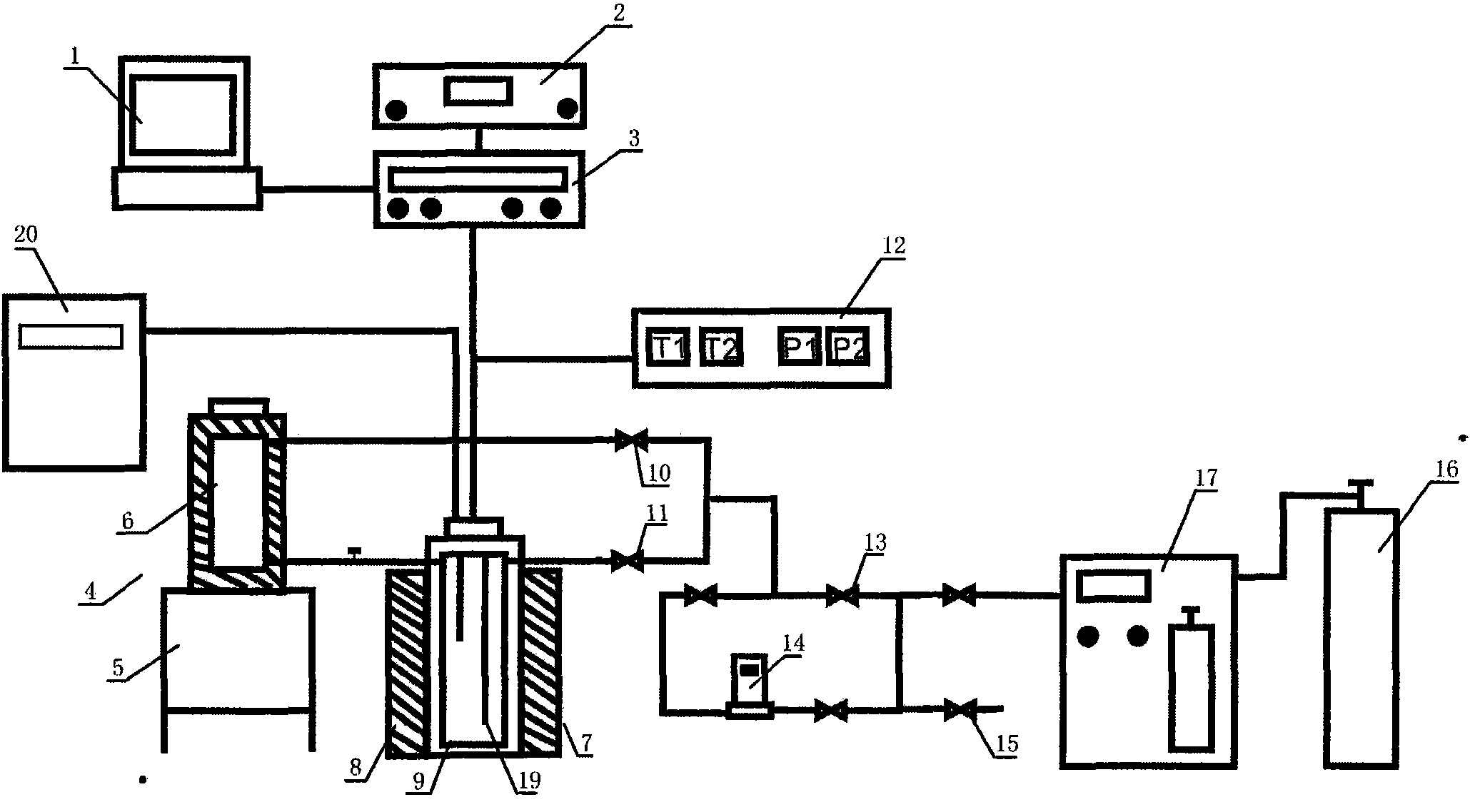

[0016] The device includes a regulated gas supply unit, a saturated water preparation kettle 4, a hydrate reaction kettle 7, a constant temperature controller 20, and a data acquisition and processing unit. The hydrate reactor 7 is connected; the saturated water preparation kettle 4 is connected to the hydrate reactor 7 through pipelines; the hydrate reactor 7 is electrically connected to the thermostatic controller 20 and the data acquisition and processing unit respectively.

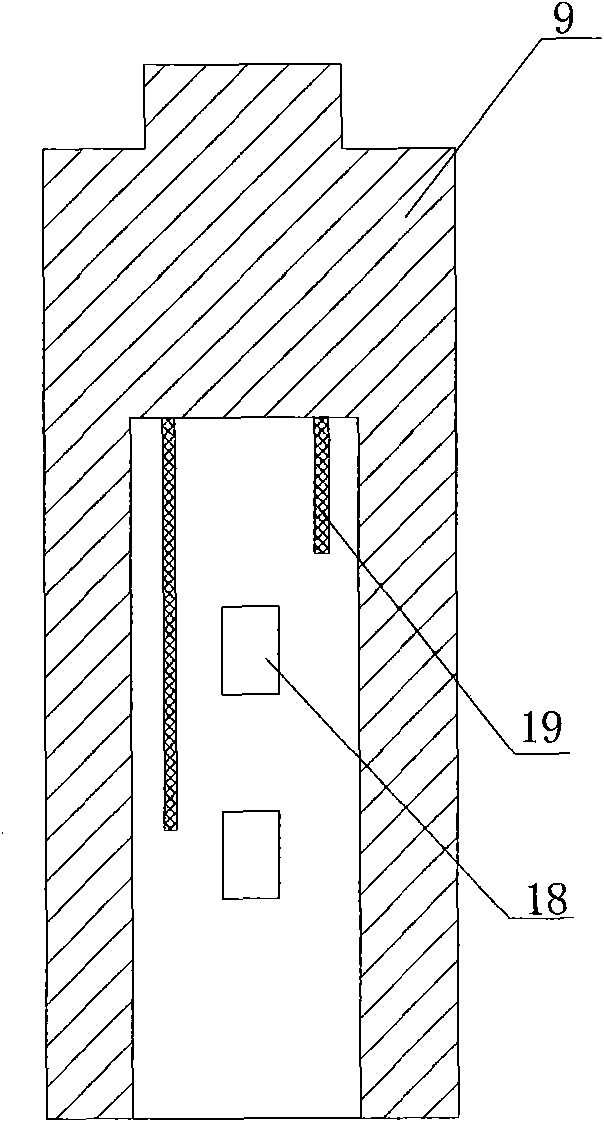

[0017] The hydrate reaction kettle 7 includes an outer cylinder 8, the outer cylinder 8 is provided with an inner cylinder 9, the side wall of the inner cylinder 9 is provided with a platinum electrode 18, and the center of the inner cylinder 9 is provided with two thermal resistors 19 , the platinum electrode 18 and the thermal resistor 19 are respectively electrically connected to the data acquisition and processing unit. The stabilized air supply unit includes an air supply bottle 16 and a stabilize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com