Reaping part of a combine

A technology for combine harvesters and harvesting parts, which is applied to the chassis and cutters of harvesters and agricultural implements, can solve the problems of complex structure of cutting devices, and achieve stable cutting performance, simplified structure, and reduced vibration and noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

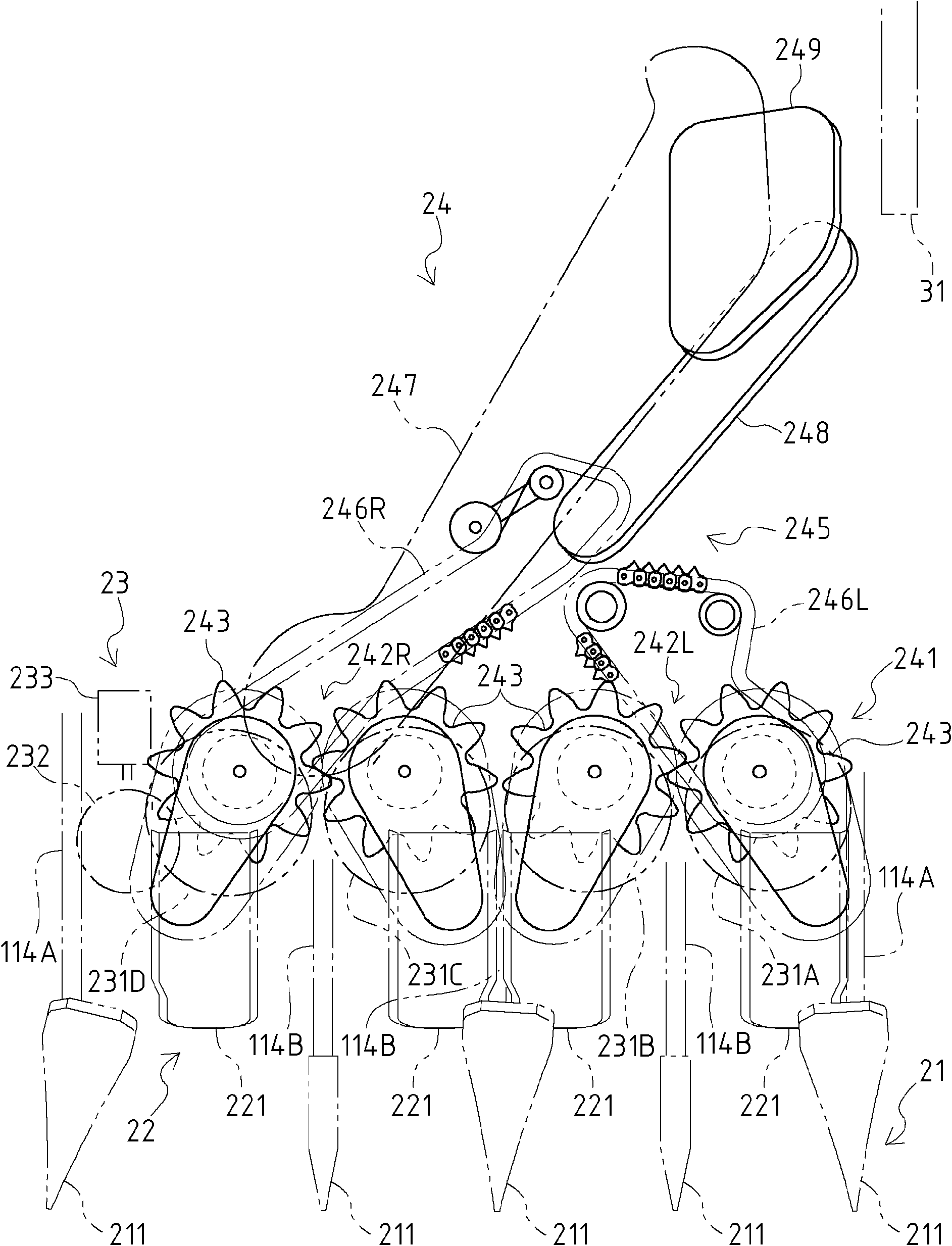

[0036] Next, embodiments of the present invention will be described.

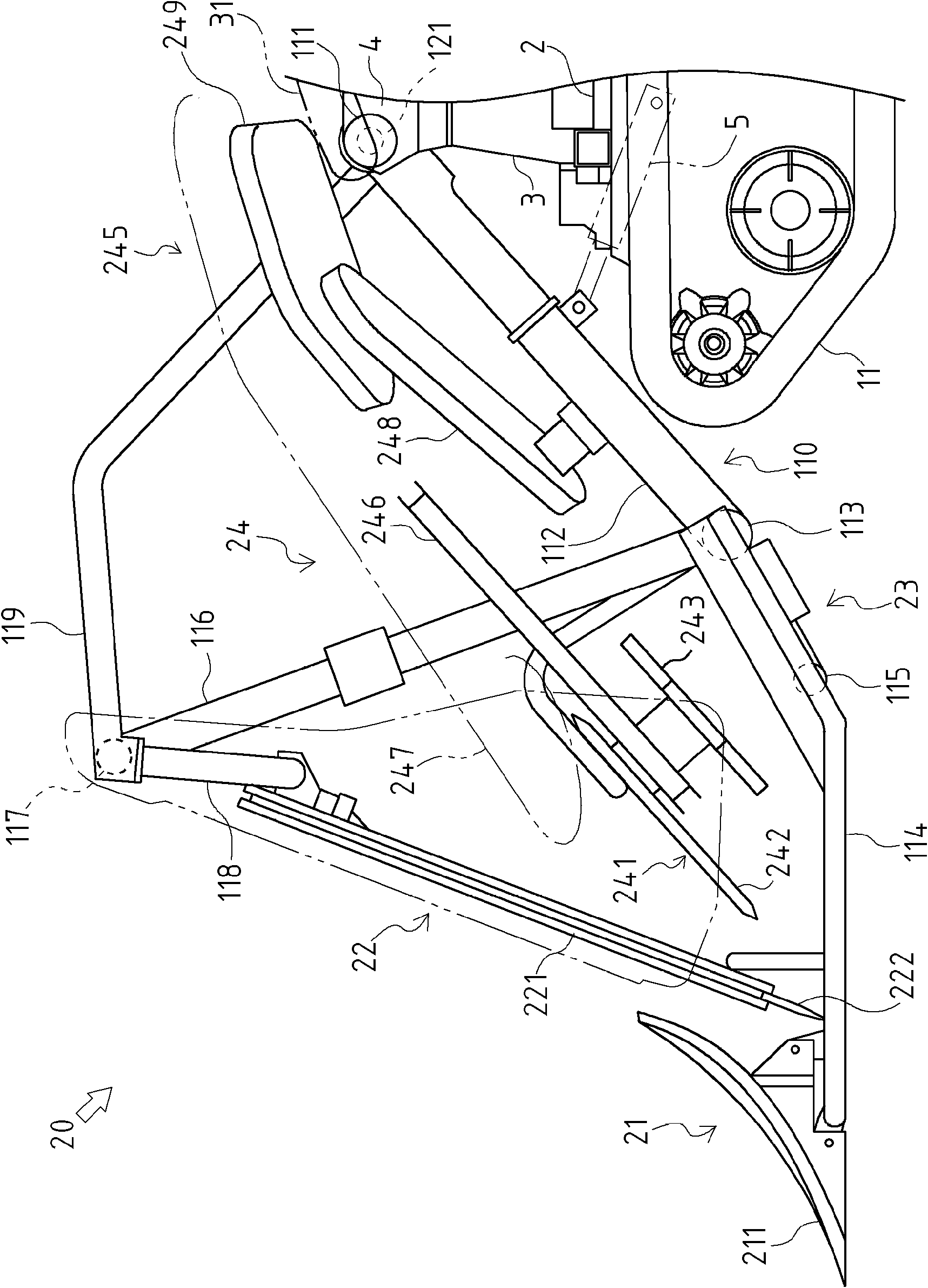

[0037] First, the whole structure of the combine 1 for four-row harvesting which has the harvesting part 20 concerning one Embodiment of this invention is demonstrated. In addition, the harvesting part concerning this invention is not limited to the combine harvester of four-row harvesting, The combine harvester of multi-row harvesting can also be applied.

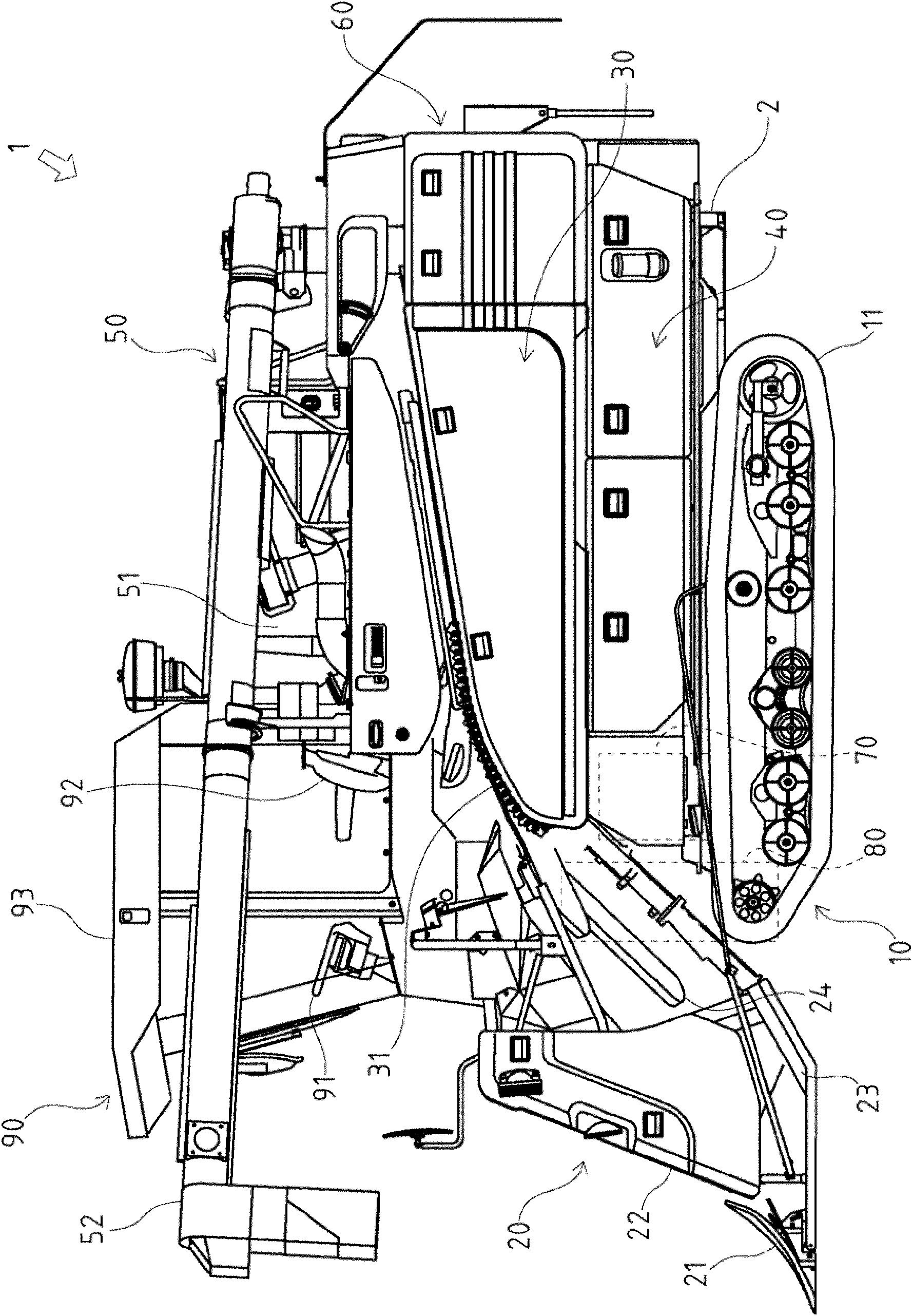

[0038] like figure 1 As shown, the combine harvester 1 is equipped with a walking part 10, a harvesting part 20, a threshing part 30, a sorting part 40, a grain storage part 50, a rice straw processing part 60, an engine part 70, and a transmission part with respect to the body frame 2. 80 and the control unit 90.

[0039] The running part 10 is arranged on the lower part of the body frame 2 . The traveling unit 10 is configured to include a crawler-type traveling device 11 and the like, and the crawler-type traveling device 11 has a pair of left and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com