Multiple clutch device having two pressure equalization chambers

A multi-clutch, clutch technology, applied in clutches, fluid-driven clutches, mechanical-driven clutches, etc., can solve the problems of increased wear and tear of the first and second clutches, and achieve the effect of improved cooling and lubrication, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

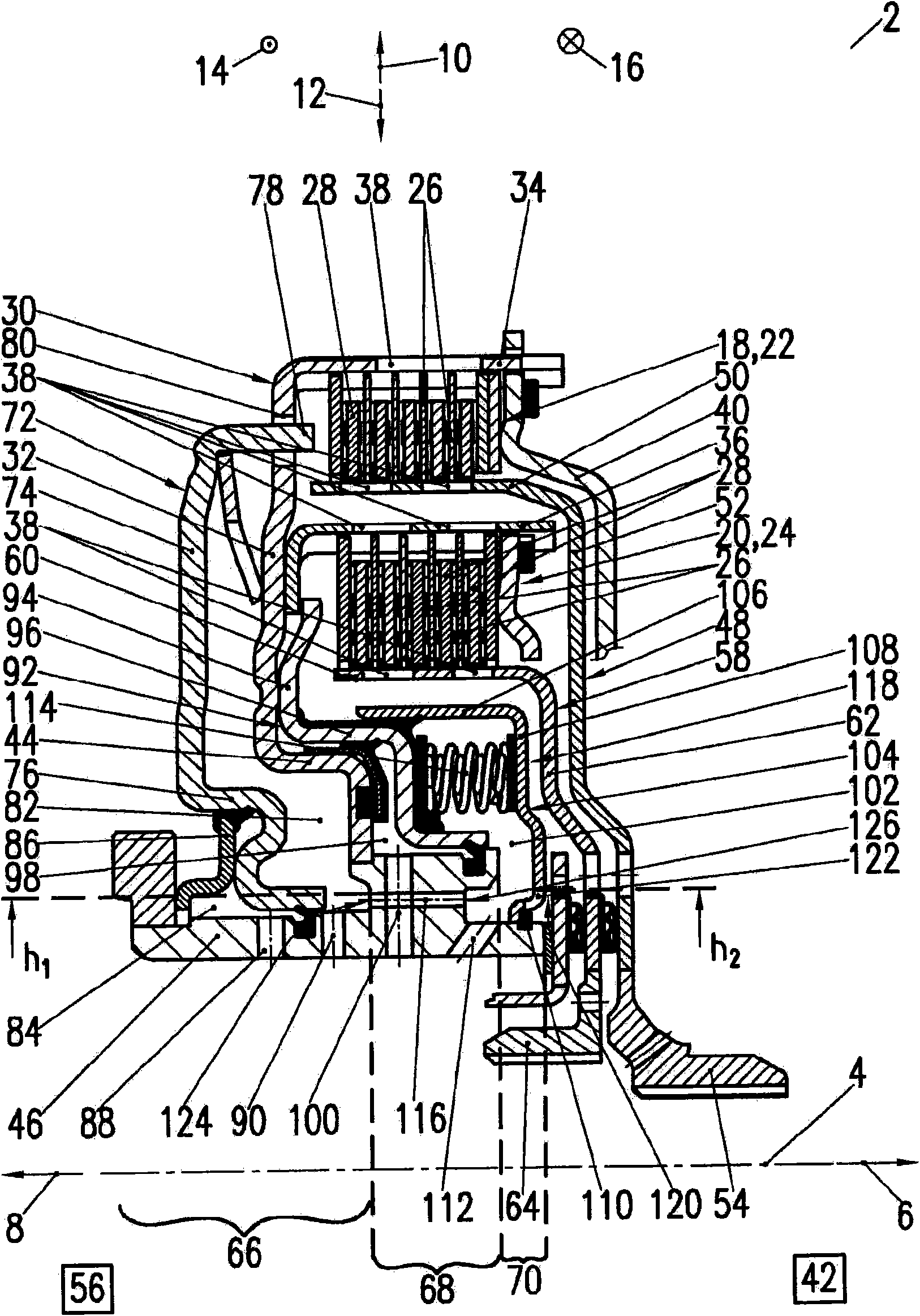

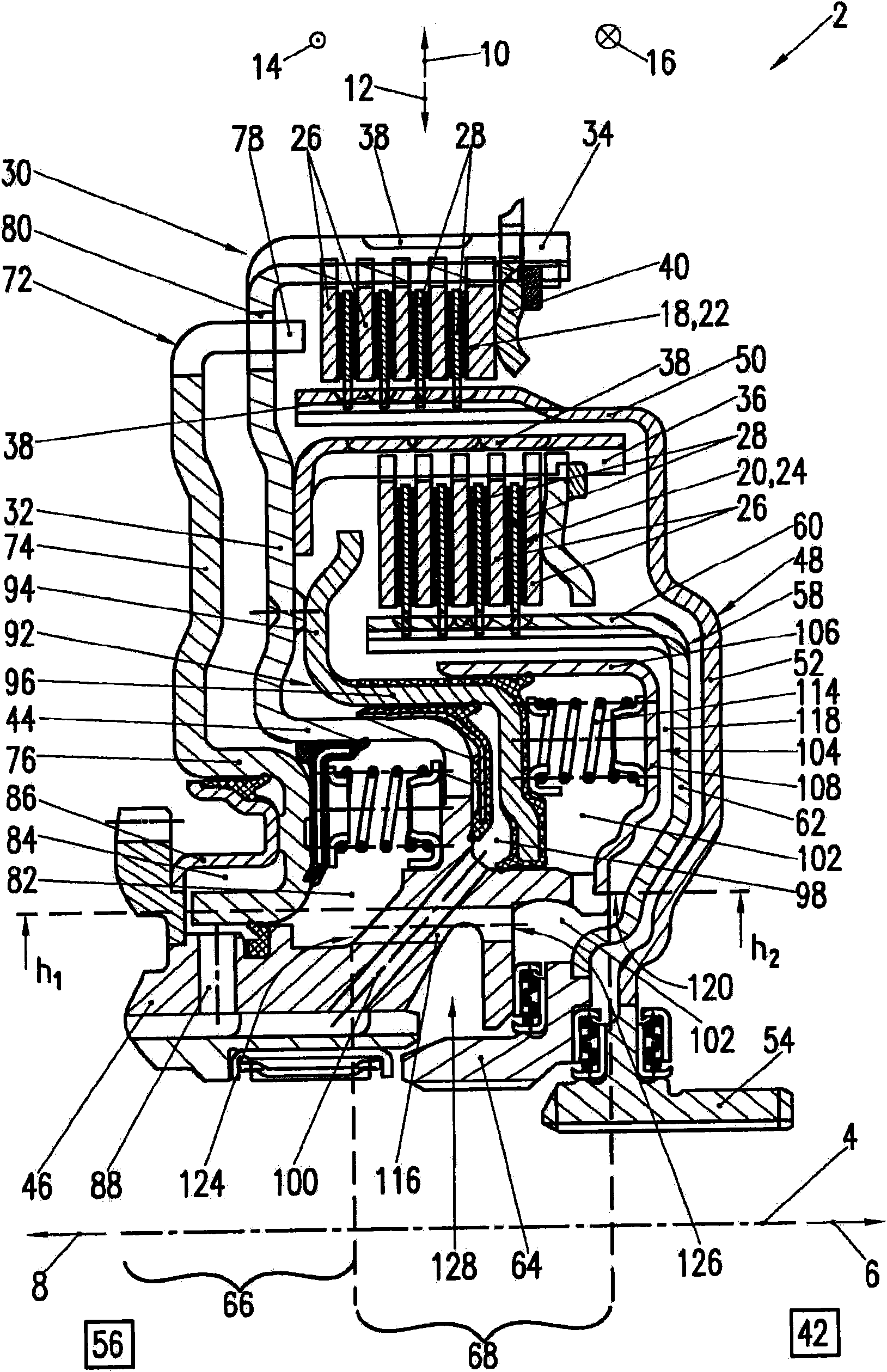

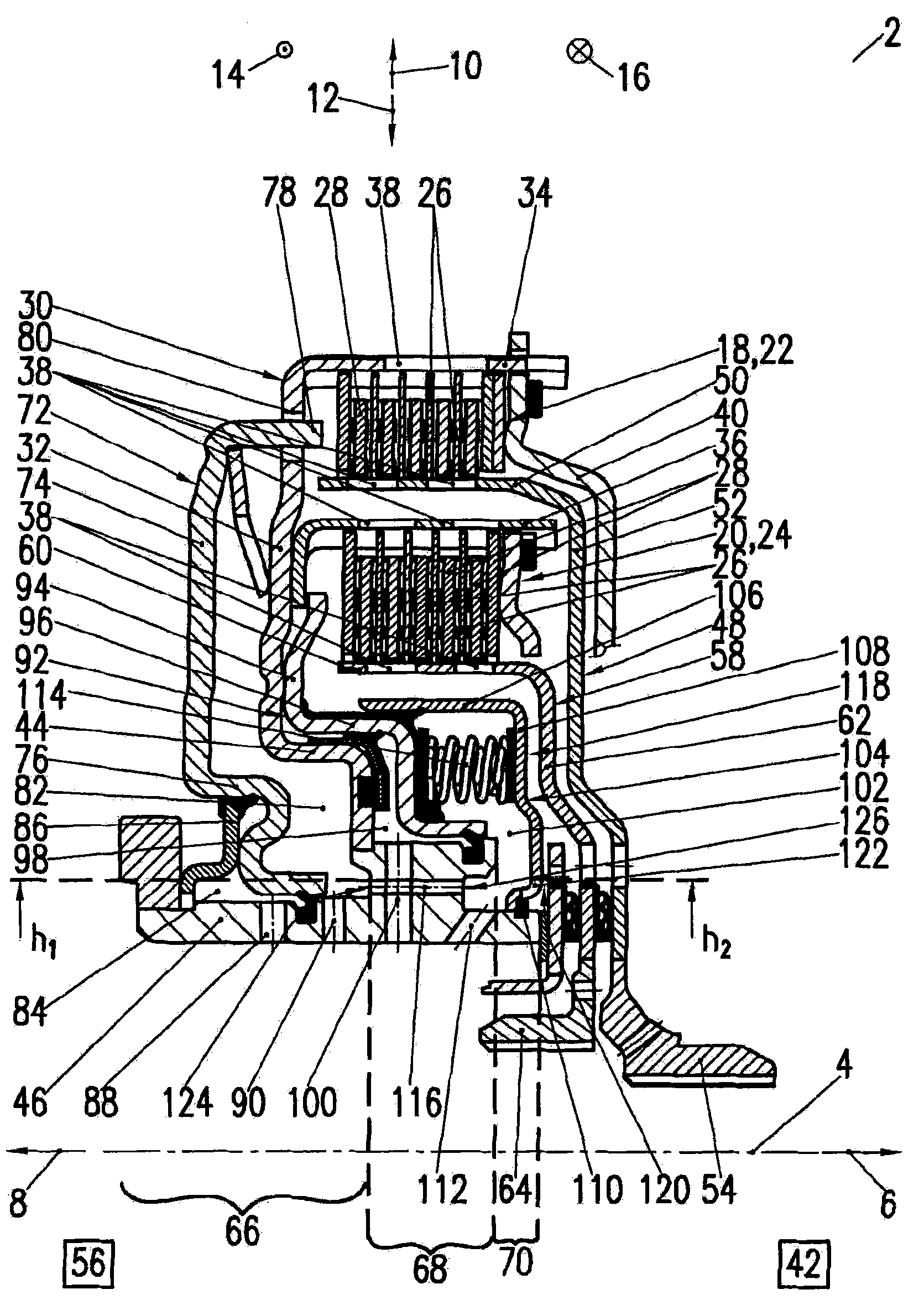

[0029] figure 1 A first embodiment of the multiple clutch arrangement 2 according to the invention is shown. The axis of rotation 4 of the multiple clutch device 2 is indicated by a dashed line. Furthermore, the opposite axial directions 6 , 8 , the opposite radial directions 10 , 12 and the opposite circumferential directions 14 , 16 of the multiclutch arrangement 2 are indicated by corresponding arrows.

[0030] The multiclutch arrangement 2 has a first clutch 18 and a second clutch 20 , with the result that the multiclutch arrangement 2 in the embodiment shown is a double clutch. Here, the first clutch 18 and the second clutch 20 are arranged in a nested manner in the radial direction 10 , 12 , that is to say the first clutch 18 surrounds the second clutch 20 from the outside in the radial direction 10 , For this reason, the first clutch 18 can also be referred to as an outer clutch, and the second clutch 20 can also be referred to as an inner clutch. This is also a conc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap