Heat exchanger

A technology for heat exchangers and heat conduction parts, applied to heat exchange equipment, indirect heat exchangers, heat exchanger types, etc., can solve the problem of reduced drainage and achieve high contact reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, the following embodiments are only specific examples of the present invention, and do not limit the technical scope of the present invention.

[0028]

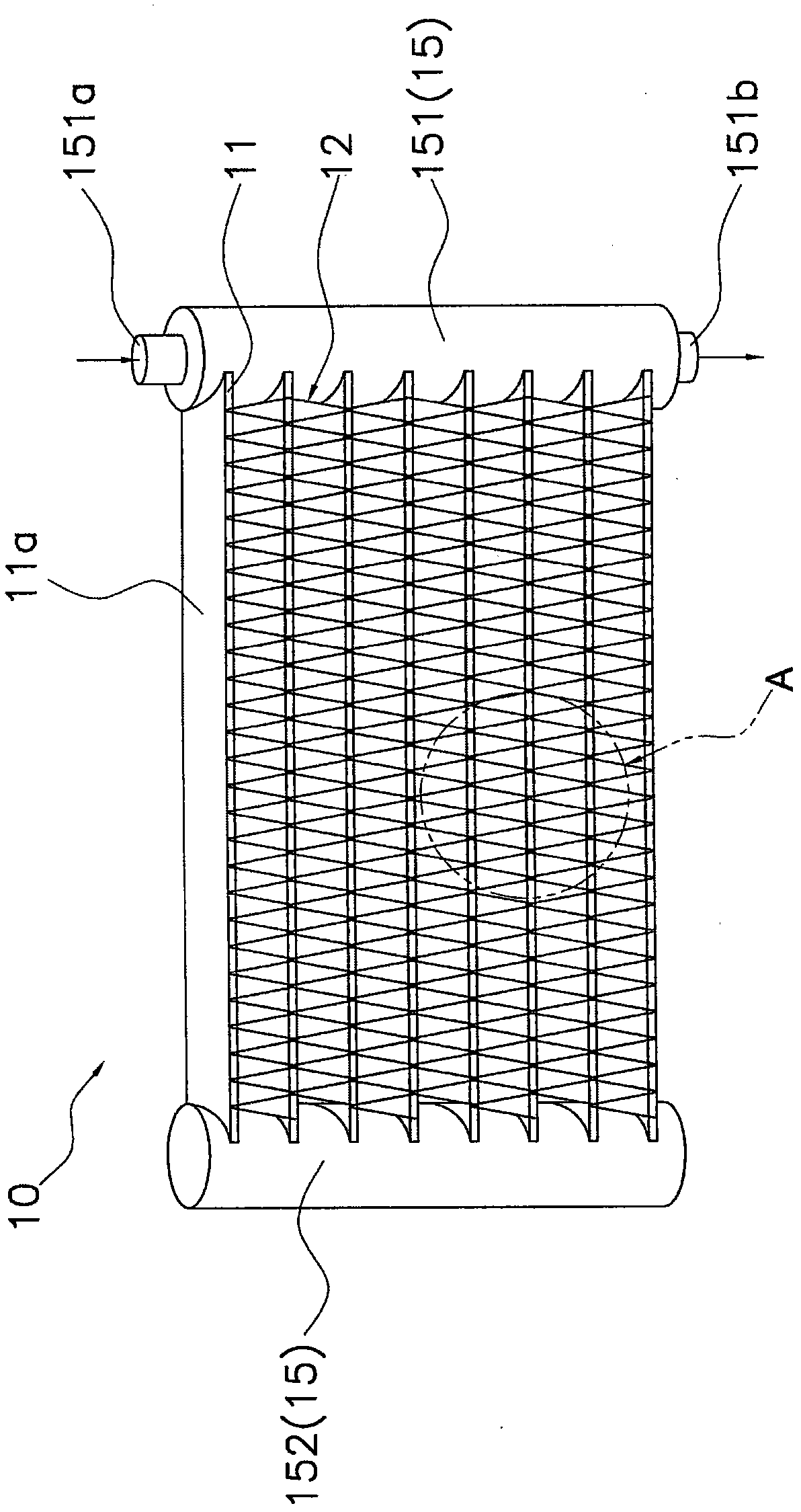

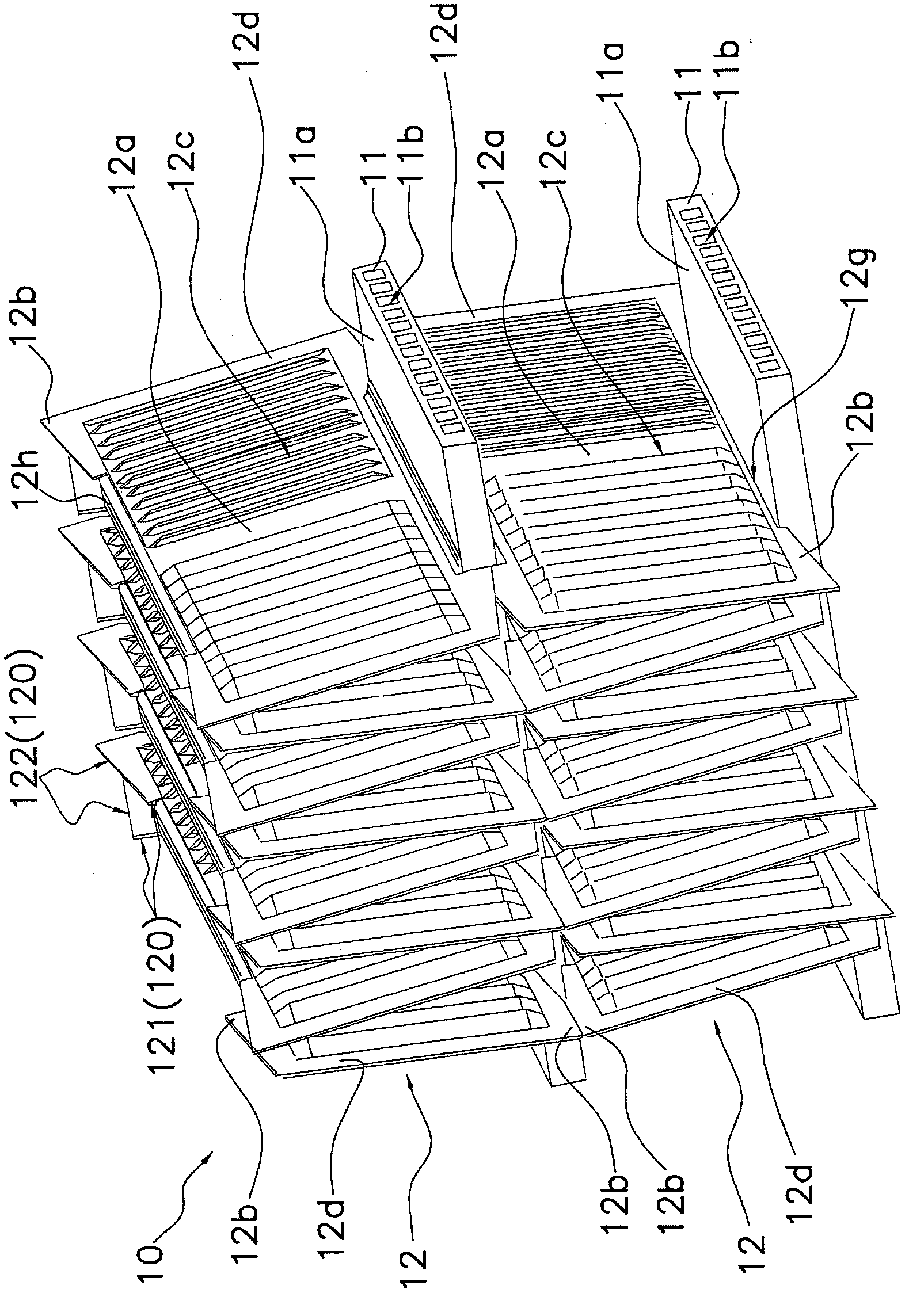

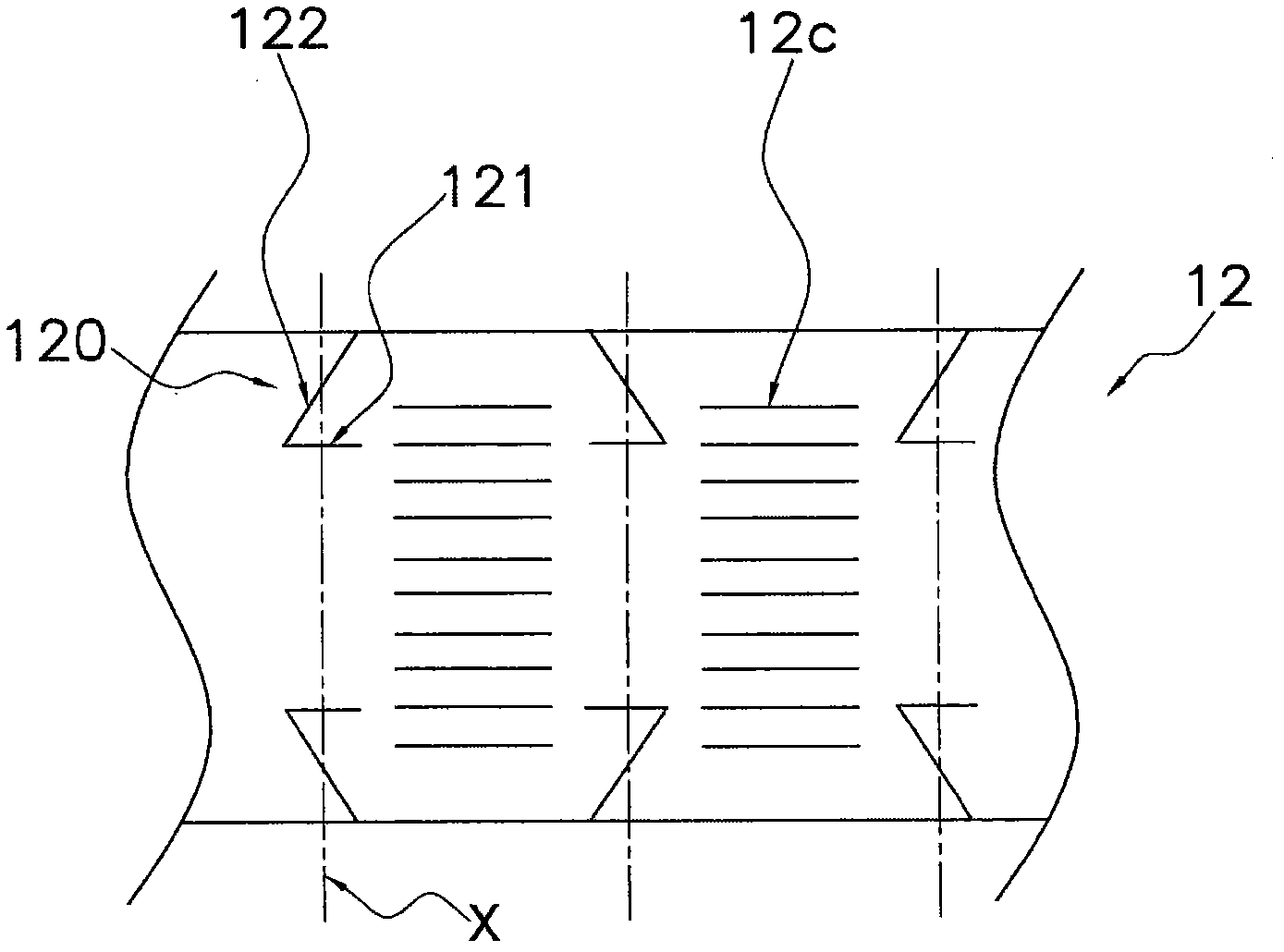

[0029] figure 1 is an external perspective view of a heat exchanger according to an embodiment of the present invention, figure 2 yes figure 1 An enlarged perspective view of part A of . exist figure 1 , figure 2 Among them, the heat exchanger 10 includes flat tubes 11 , corrugated fins 12 , and headers 15 .

[0030] (flat tube 11)

[0031] The flat tube 11 is formed of aluminum or an aluminum alloy, and has a flat portion 11a serving as a heat transfer surface and a plurality of refrigerant passages 11b through which the refrigerant flows (refer to figure 2 ). Such as figure 2 As shown, the flat tubes 11 are arranged in a plurality of stages with the planar portions 11a facing the up-down dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com