Sound absorbing structure

A technology of structural body and frame body, applied in the direction of sound-producing equipment, instruments, etc., can solve the problem of narrow sound-absorbing band, and achieve the effect of improving sound-absorbing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0201] Next, specific examples of the present invention will be described.

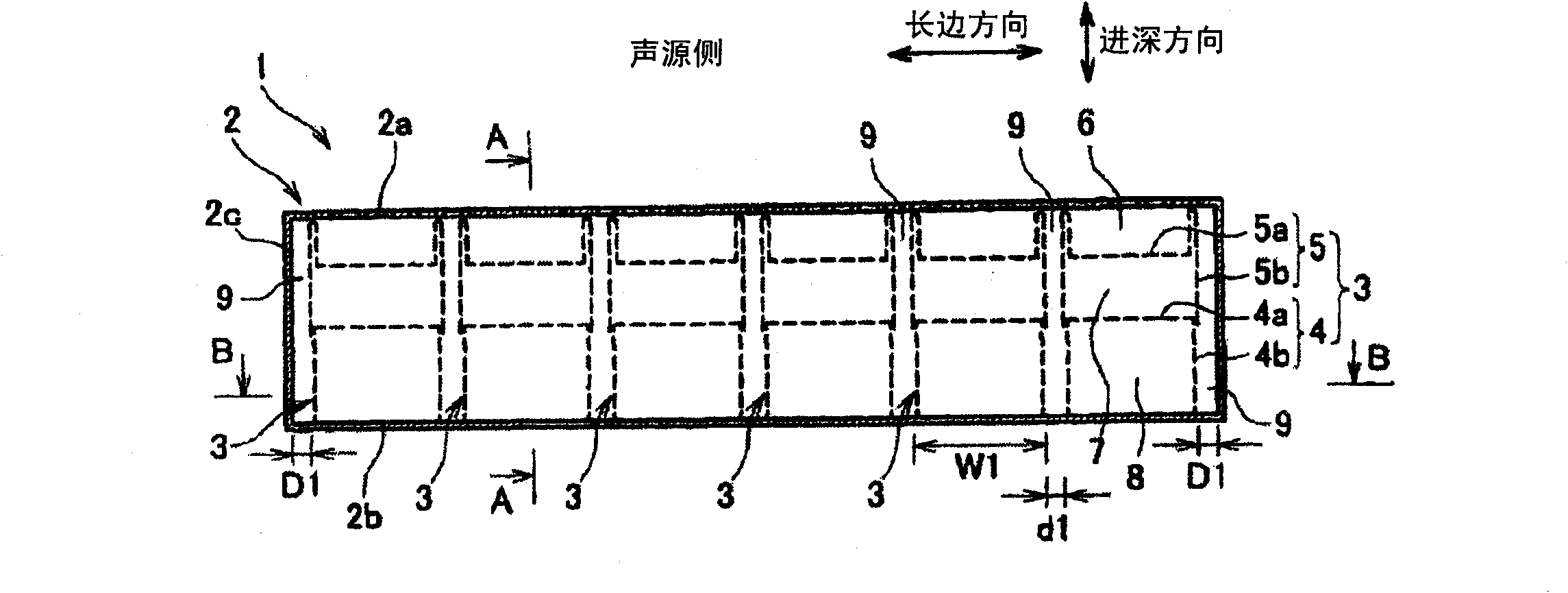

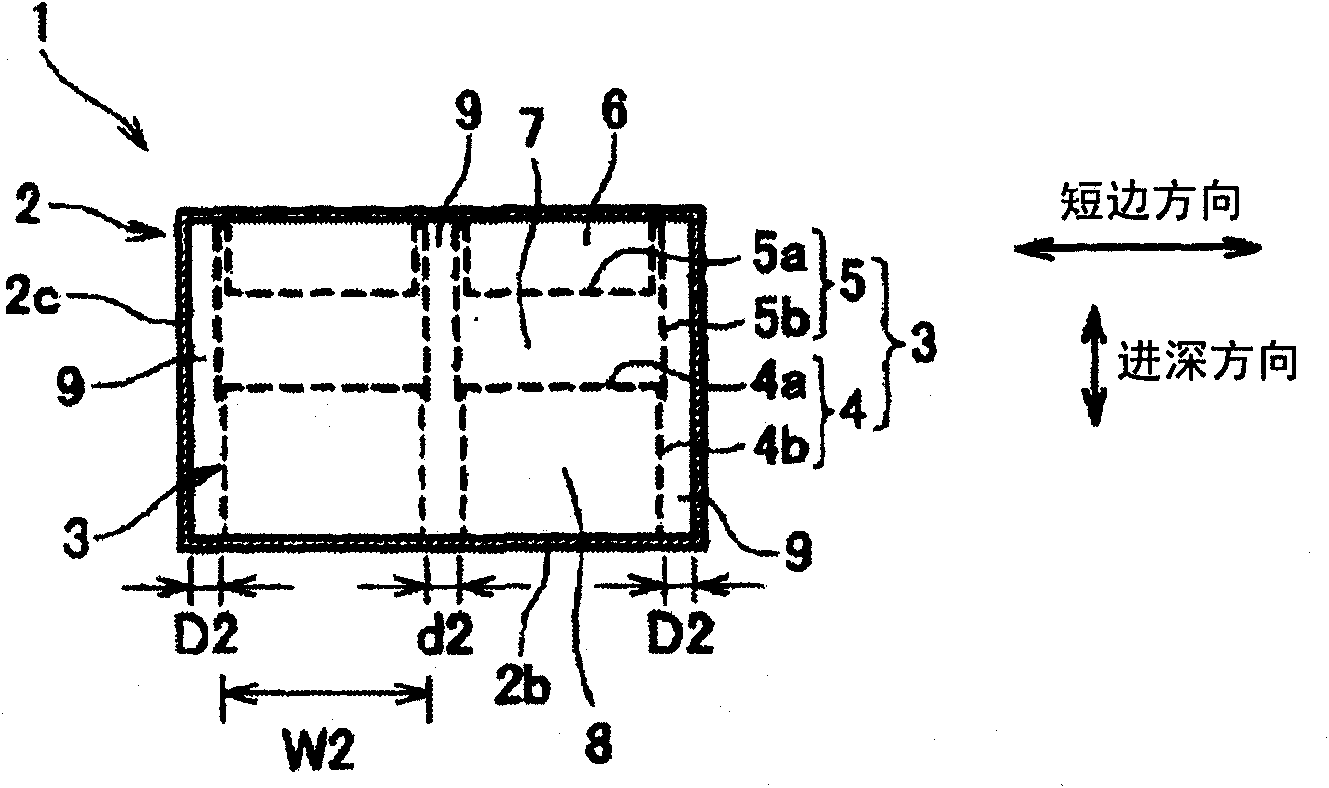

[0202] As an example, make Figure 17A as well as Figure 17B The sound absorbing structure 801 is shown. The sound-absorbing structure 801 of the embodiment includes six perforated plate units 803 , and the six perforated plate units 803 are arranged along the longitudinal direction inside the frame body 802 . As the porous plate unit 803, a porous plate unit having the same structure as the porous plate unit 3 of the first embodiment is used. In the sound-absorbing structure 801 of the embodiment, the respective plate thicknesses, aperture ratios, and diameters of the through holes of the surface plate 802a, the planar portions 804a, 805a, and the side portions 804b, 805b, and the sizes of the air chambers 806-808 and the gaps D1, d1 are as follows: Table 1 shows.

[0203] 【Table 1】

[0204]

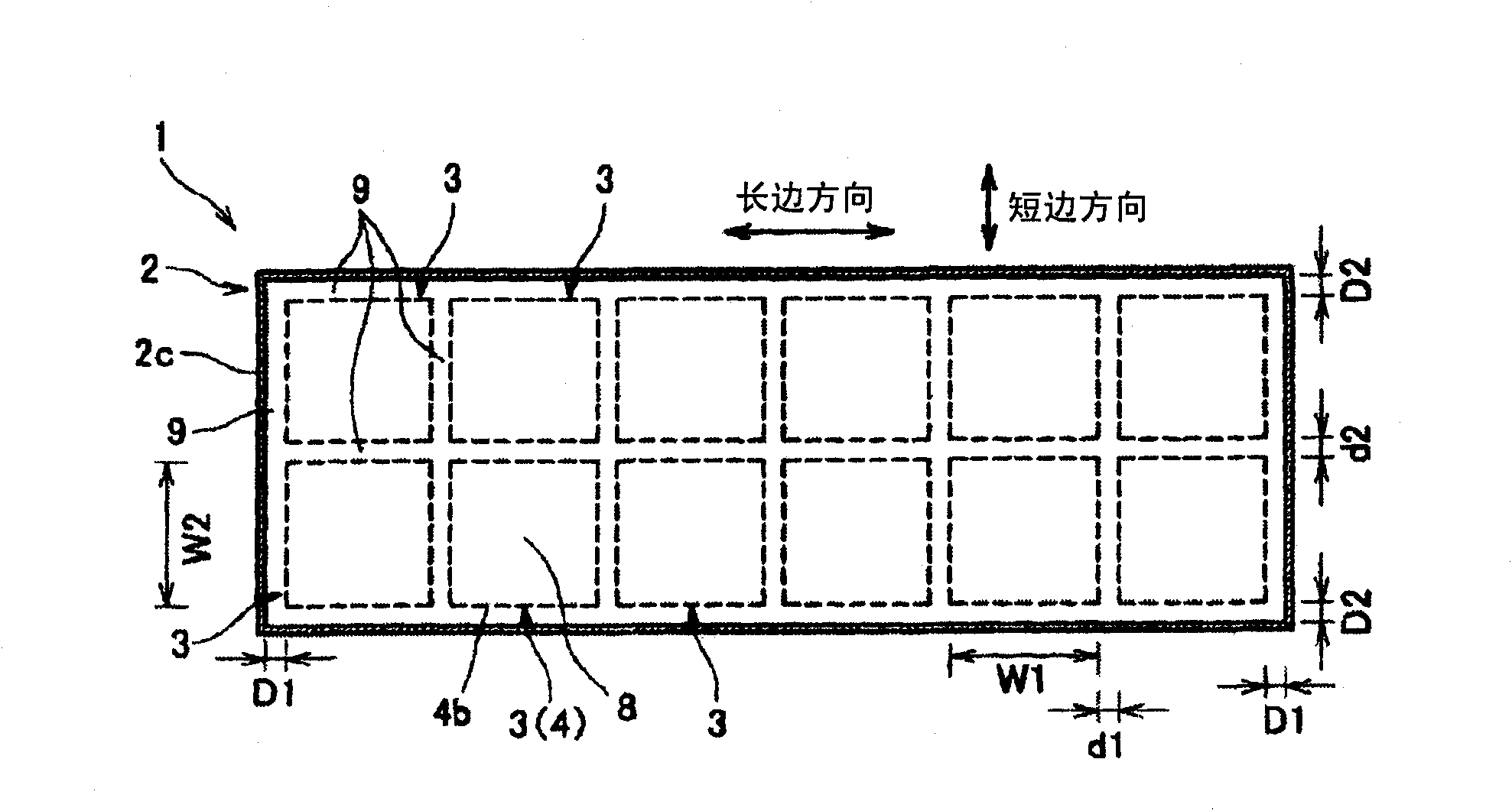

[0205] As a comparative example, make Figure 18A as well as Figure 18B An existing attraction st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com