Separated safety run-flat spring tyre

A discrete, secure technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

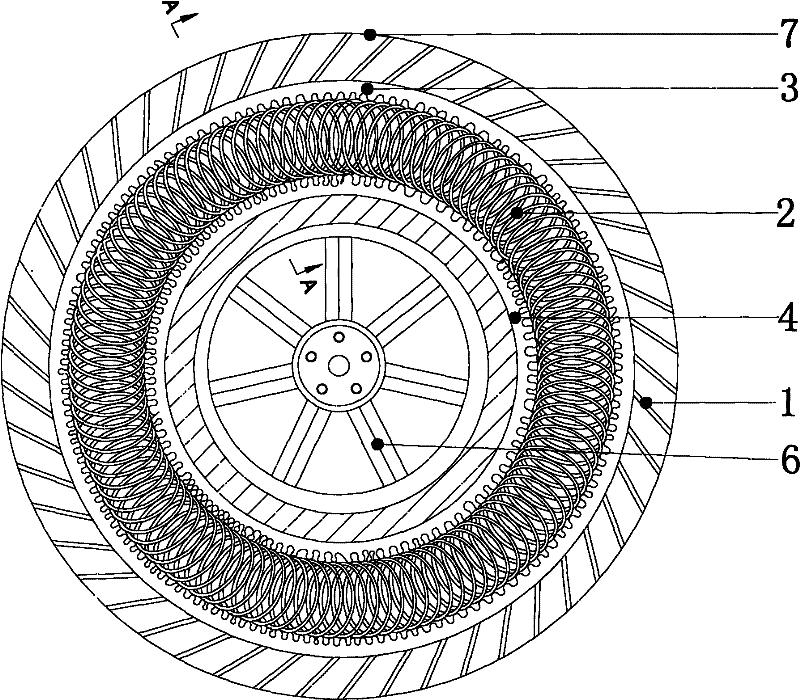

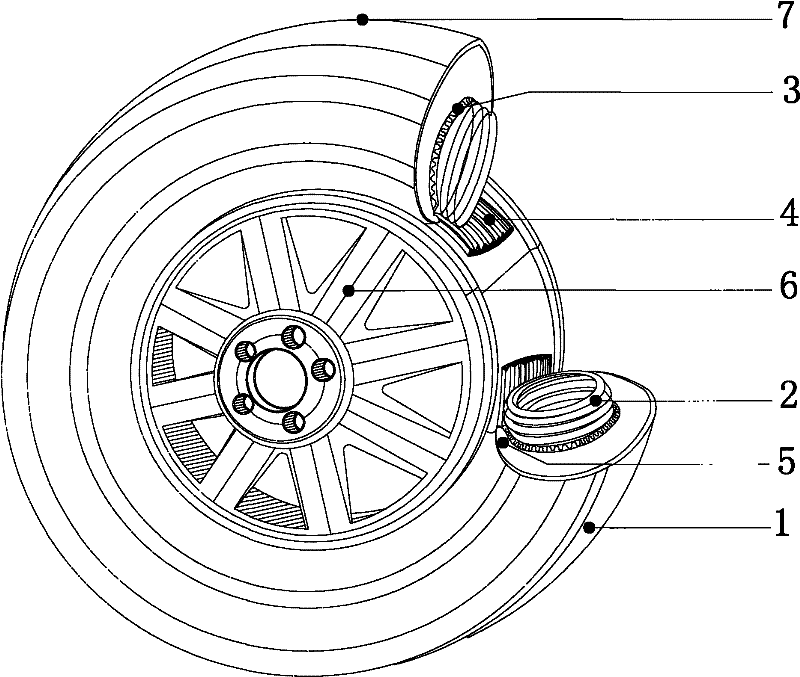

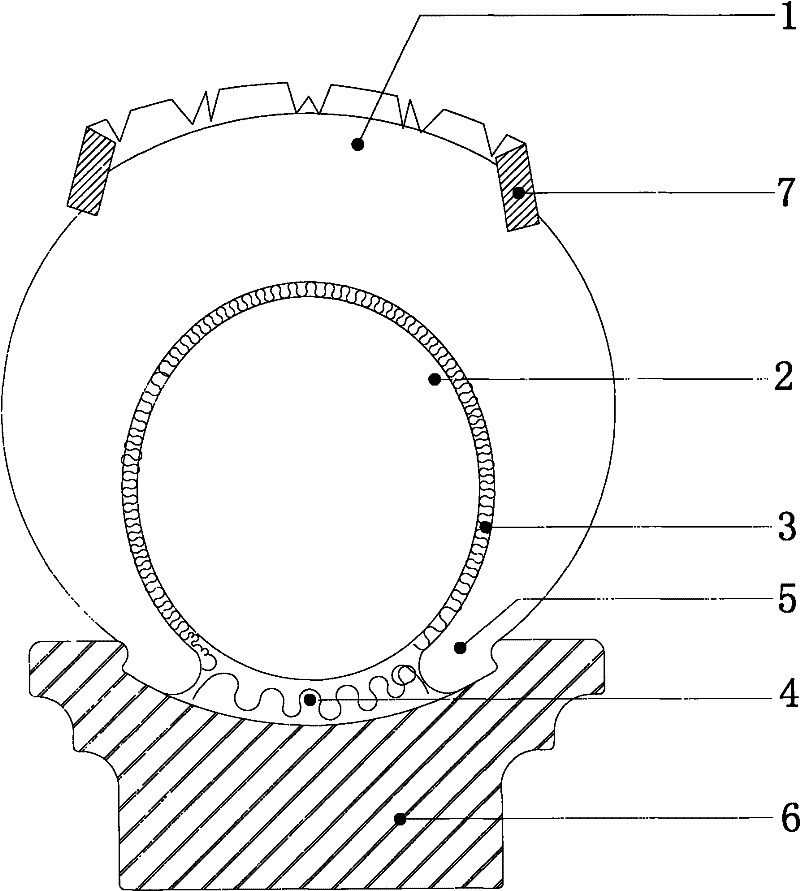

[0017] This embodiment provides a separate safety explosion-proof spring tire, comprising a carcass outer side 1 and a rim 6, the inner surface of the carcass outer side 1 is provided with a compression spring 2 matching the tire, and the compression spring 2 and the tire A carcass stabilizing layer 3 is provided between the outer sides of the carcass 1; the crown 5 of the outer carcass 1 is closely attached to the rim 6, and a rim cushion 4 is arranged between the crown 5 and the rim 6 and are matched with each other . The outer surface of the outer carcass 1 is provided with an outer body gear 7 . Both the outer side of the carcass 1 and the compressed spring 2 are annular, wherein the compressed spring 2 is attached to the inner surface of the outer side of the carcass 1 , and its size matches that of the outer side of the carcass 1 . The compressed spring 2 is interlocked firmly with the inner surface of the carcass outer side 1 by the carcass stabilizing layer 3 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com