Electroplating device for composite plating electrodeposition

A technology of electroplating device and plating tank, which is applied in the direction of electrolytic coating, electrolytic process, electrolytic components, etc. It can solve the problems of no air inlet at the bottom of the plating tank, difficult control of the inclination angle of the cathode, unstable composite plating process parameters, etc. The effect of dispersion and stable process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

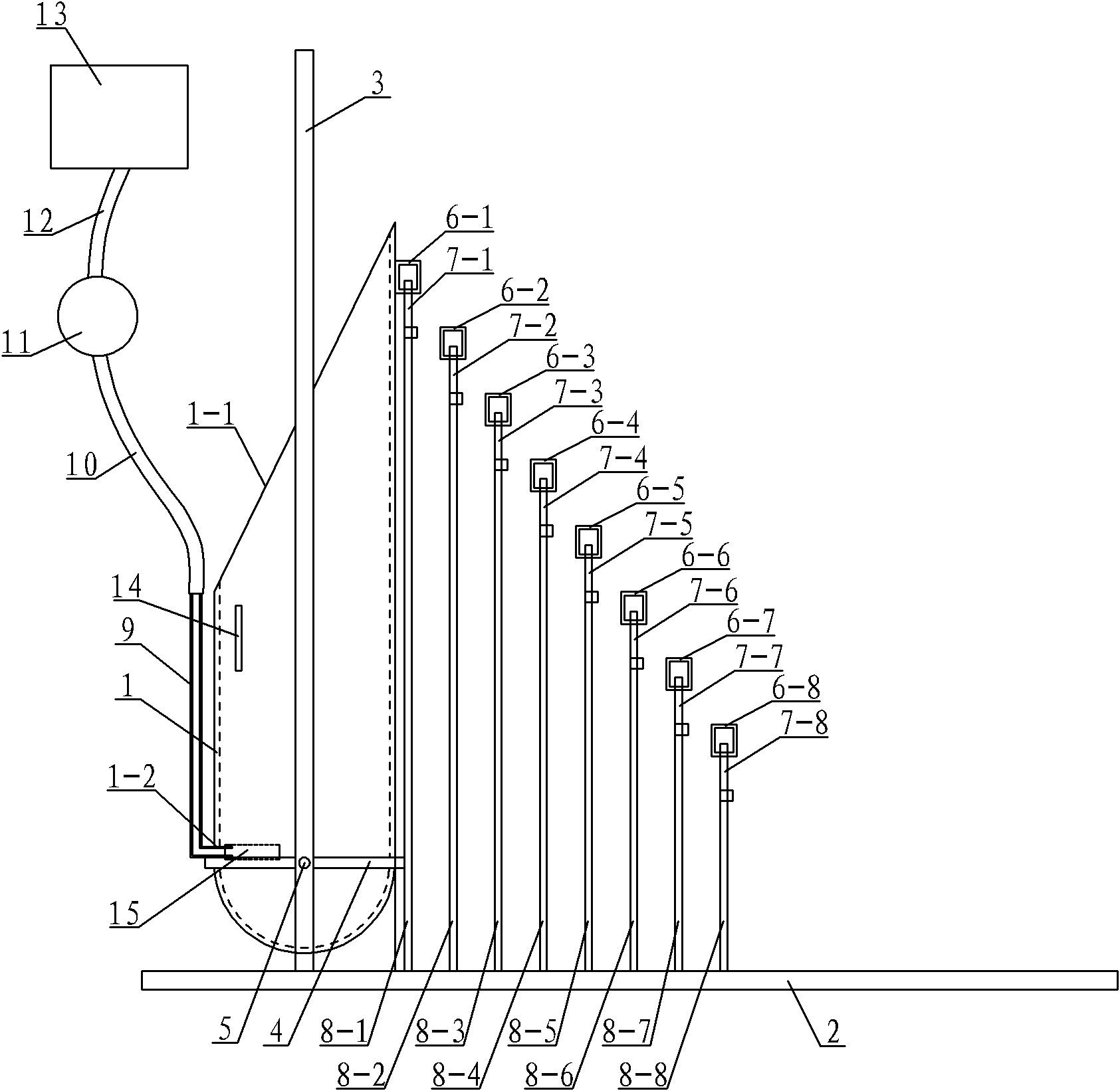

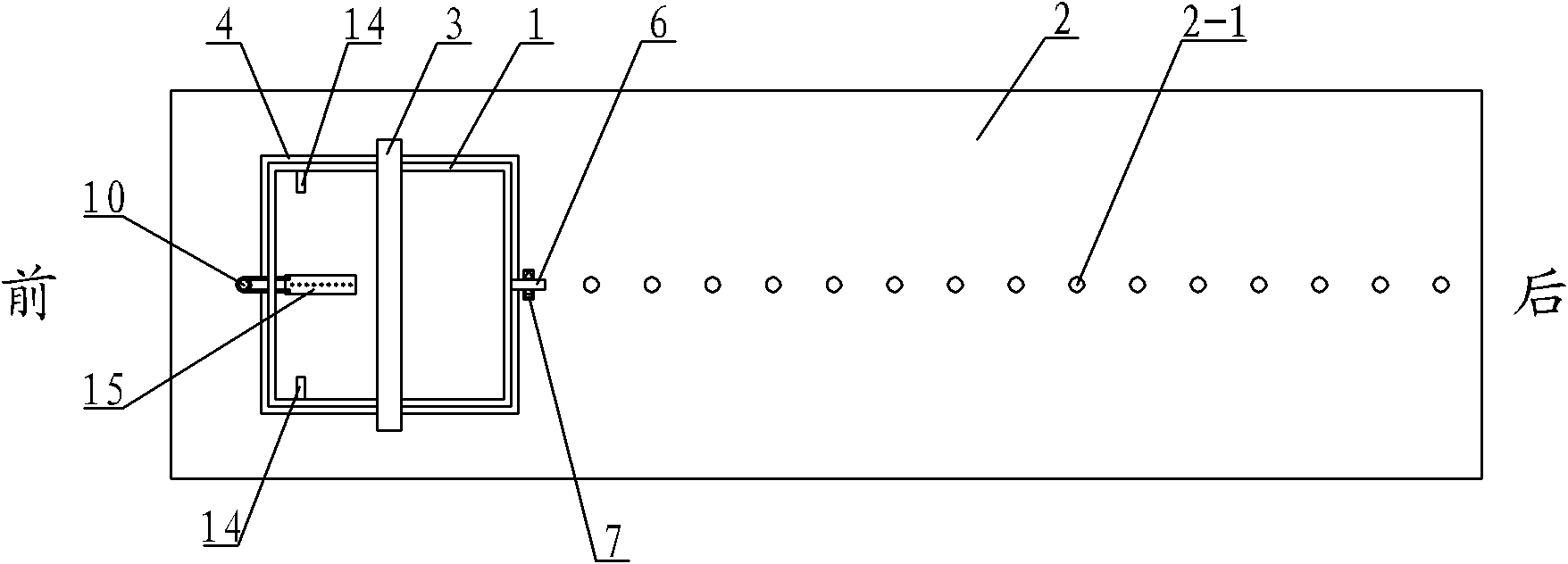

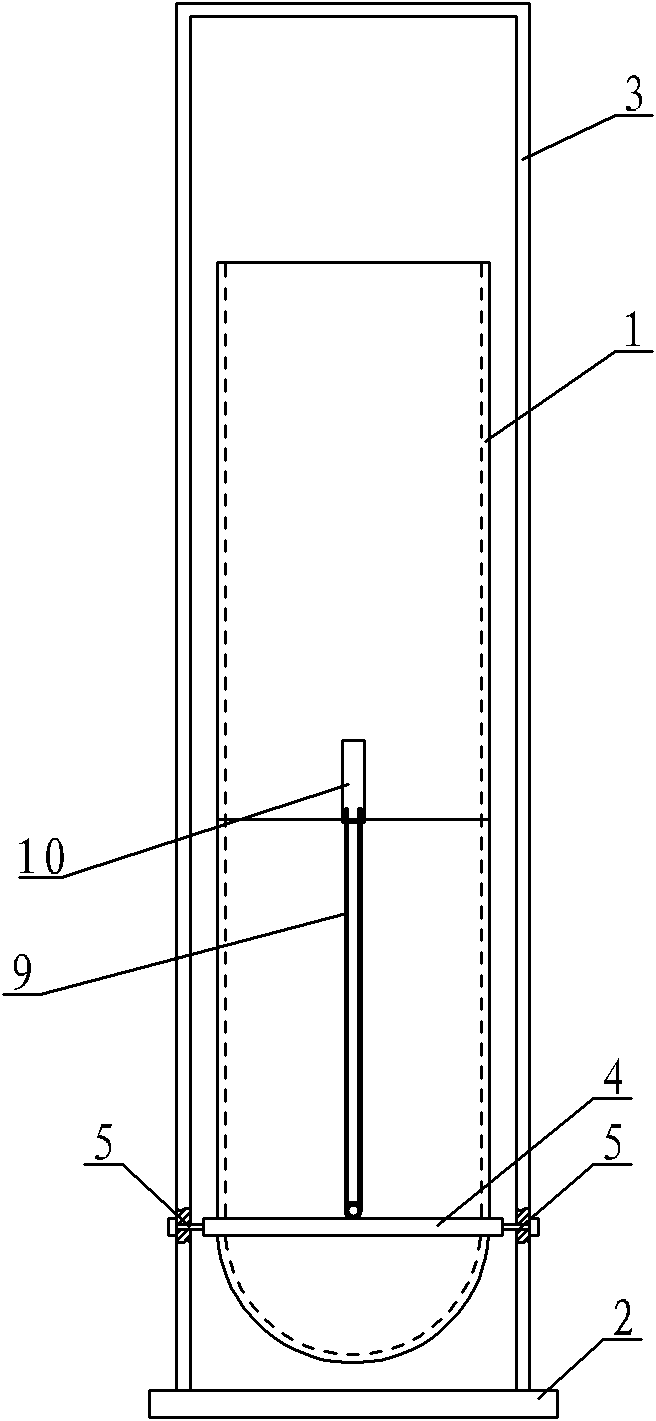

[0007] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment, this embodiment includes a plating tank 1, a base 2, a frame support 3, a plating tank fixing ring 4, two rotating shafts 5, a first adjusting square ring 6-1, a first hook 7-1, a first plating tank Tank adjustment lever 8-1, the second adjustment square circle 6-2, the second hook 7-2, the second plating tank adjustment lever 8-2, the third adjustment square circle 6-3, the third hook 7-3, the second Three plating tank adjustment rods 8-3, fourth adjustment square rings 6-4, fourth hooks 7-4, fourth plating tank adjustment rods 8-4, fifth adjustment square rings 6-5, fifth hooks 7-5 , The fifth plating tank adjustment rod 8-5, the sixth adjustment square ring 6-6, the sixth hook 7-6, the sixth plating tank adjustment rod 8-6, the seventh adjustment square ring 6-7, the seventh hook 7 -7, the seventh coating tank adjustment rod 8-7, the eighth adjustment square ring 6-8, the eight...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment, the difference between this embodiment and specific embodiment 1 or 2 is that it also adds an air outlet pipe 15, and the air outlet pipe 15 is provided with a plurality of air outlet holes, and the air outlet pipe 15 is connected with the output end of the ventilation pipe 9. This design makes the air outlet pipe 15 replaceable and can be taken out for cleaning at any time. Multiple air outlets make the plating solution of composite plating more evenly stirred. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 and Figure 5 To describe this embodiment, the air outlet pipe 15 of this embodiment is straight or Y-shaped. This design is suitable for plating tanks 1 of different sizes. When the outlet pipe 15 is Y-shaped, the lower end of the Y-shape is connected with the vent pipe 9 . Other components and connections are the same as those in the first embodiment.

[0010]The working principle of this device: the anode plate 16 is inserted between the tank wall of the coating tank 1 and the fixed plate 14, and then hung on the inner wall of the coating tank 1 to fix it, and the cathode plate 17 is hung in the coating tank 1 and connected with the On the opposite inner wall of the anode plate 16, the anode plate 16 and the cathode plate 17 are respectively connected with the anode and the cathode of the power supply 18 by wires; add an appropriate amount of plating solution in the plating tank 1, open the air pump 13, adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com