Dynamic dyeing control method of textiles

A control method and textile technology, applied in the field of textile printing and dyeing, can solve the problems of color difference, hairiness, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

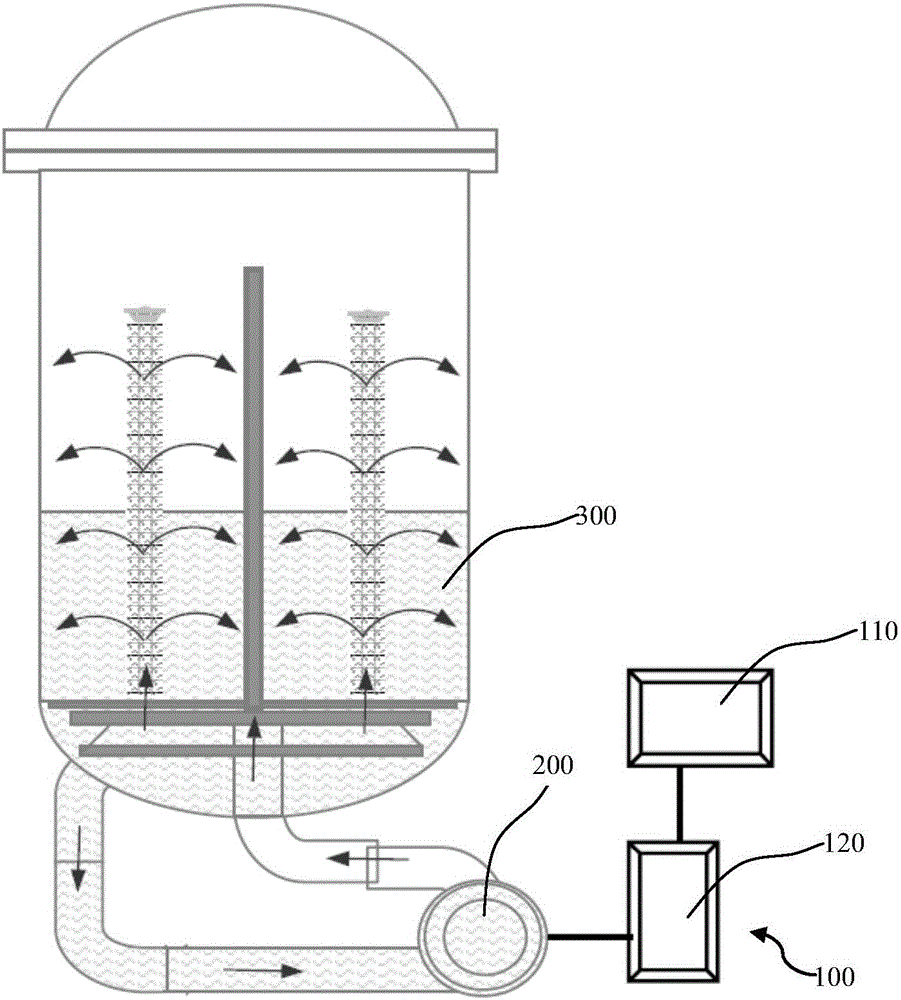

Method used

Image

Examples

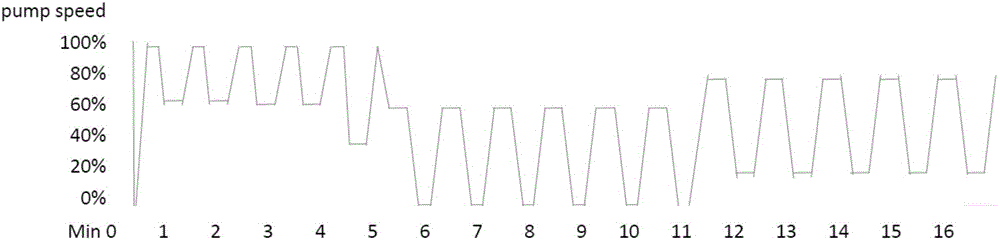

Embodiment 1

[0031] Such as figure 2 As shown, in the dyeing process stage, in the initial stage (0-5min), the fibers need to be fully wetted to ensure sufficient exchange between the dye solution and the fibers, so the highest pump speed is set to 100%, and the lowest pump speed is set to 70% cycled. In the second stage (5-10 minutes), after the fiber is fully wetted, the dyeing preparation is added, because the addition of the dyeing preparation has a greater impact on the dyeing system environment (such as pH changes, etc.), in order to delay the severe environmental degradation of the dyeing system Changes may cause quality risks, so the highest pump speed is set at 60%, and the lowest pump speed is set at 0% for circulation. In the third stage (10-15 minutes), after the dyeing preparation is added, the environment of the dyeing system is basically stable, and the dyeing preparation and dyes in the dyeing liquor begin to exchange, react, and combine with the fibers. At this stage, a ...

Embodiment 2

[0033] Select the same yarn count and the same batch of pure cotton yarn, and arrange the dyeing of the following formula in Table 1.

[0034] Table 1

[0035] dye combination Dosage (specific gravity of dyestuff to textile) reactive yellow dye 0.006% reactive red dye 0.1% reactive blue dye 0.25%

[0036] Proceed as follows:

[0037] (1) input pretreatment, dyeing, posttreatment program by the dyeing process of embodiment 1 in the machine platform;

[0038] (2) Hang the cotton yarn into the cylinder, lock the cylinder head and complete the pretreatment, dyeing and posttreatment processes according to the program requirements;

[0039] (3) Open 5 layers of cotton yarn for visual inspection and computer testing (take the first layer, that is, the outermost layer of cotton yarn as the standard, and test the dyeing quality of the second to fifth layers of cotton yarn).

[0040] (4) During the entire dyeing process, the dynamic dyeing process of...

Embodiment 3

[0042] The dyeing process parameters and steps are the same as in Example 2, and the dyeing formula is changed in the following table 2.

[0043] Table 2

[0044] dye combination Dosage (specific gravity of dyestuff to textile) reactive turquoise dye 0.05% reactive yellow dye 0.004% reactive blue dye 0.15%

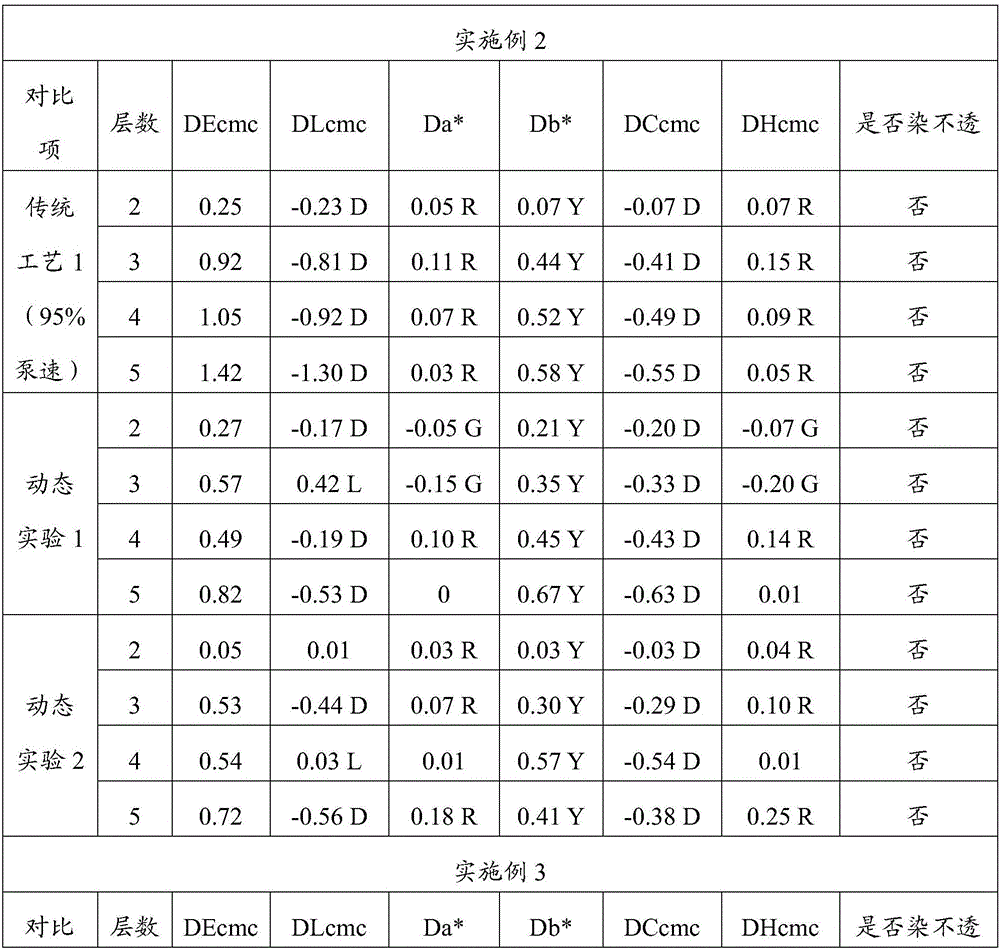

[0045] See Table 3 for the comparison of the dyeing quality of pure cotton yarns obtained by dyeing in Examples 2 and 3. The dynamic experiment 1 among the embodiment 2 is identical with the method and train of thought of the dynamic experiment 2, and the pump speed parameter (such as pump speed or time) in the single specific implementation process is slightly different and changes, and the dynamic experiment 3 and the dynamic experiment in the embodiment 3 4 for the same reason.

[0046] table 3

[0047]

[0048]

[0049] In Table 3, DLcmc represents the lightness of the color, positive DLcmc represents lighter color, negative r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com