Automatic control system of PH value in alkaline etching and control method thereof

An automatic control system, PH value technology, applied in the direction of control/regulation system, non-electric variable control, ratio control, etc., can solve the problems of low efficiency, difficult to control PH value, etc., achieve constant process parameters, reduce ammonia consumption, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing by embodiment:

[0036] preferred embodiment

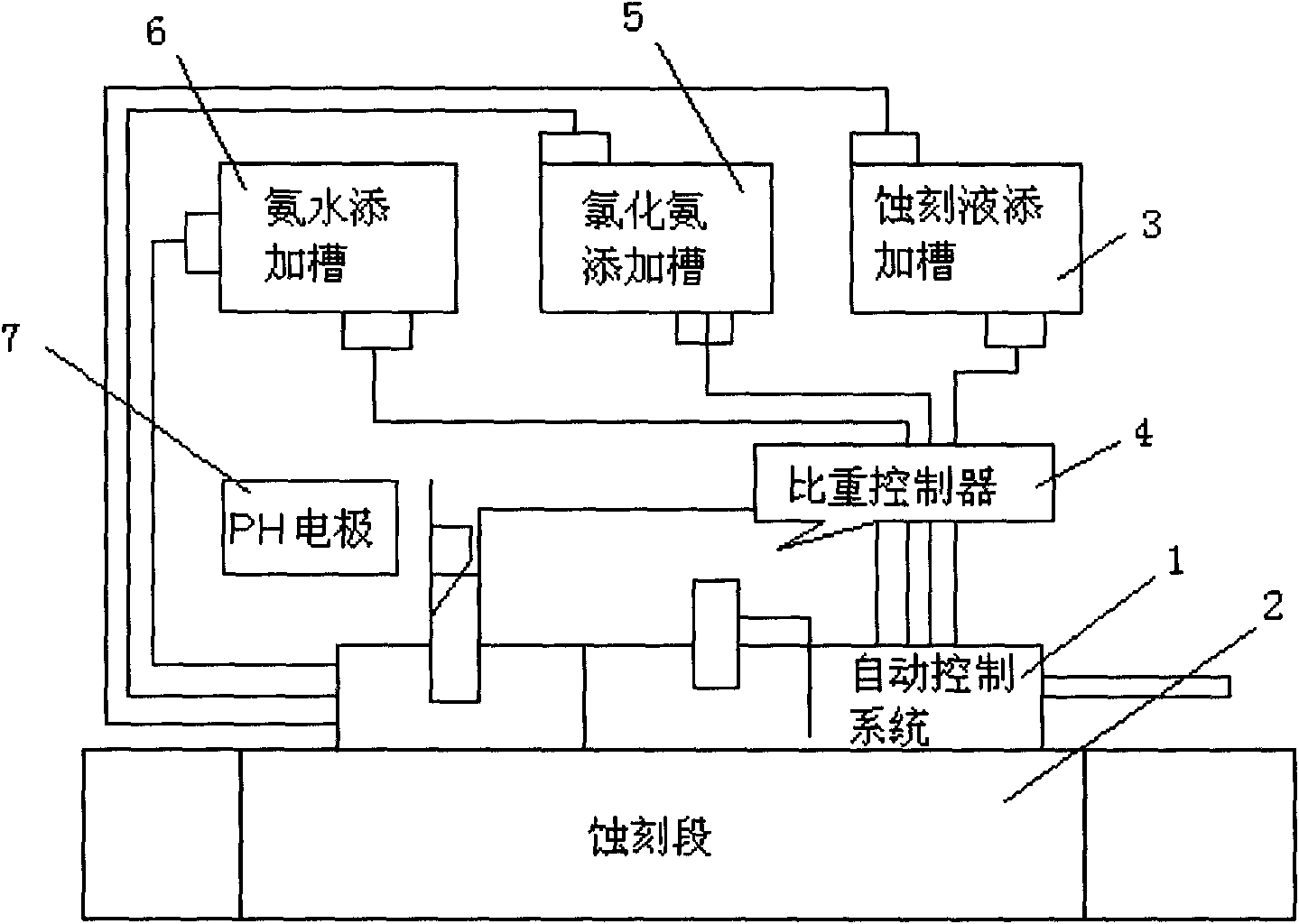

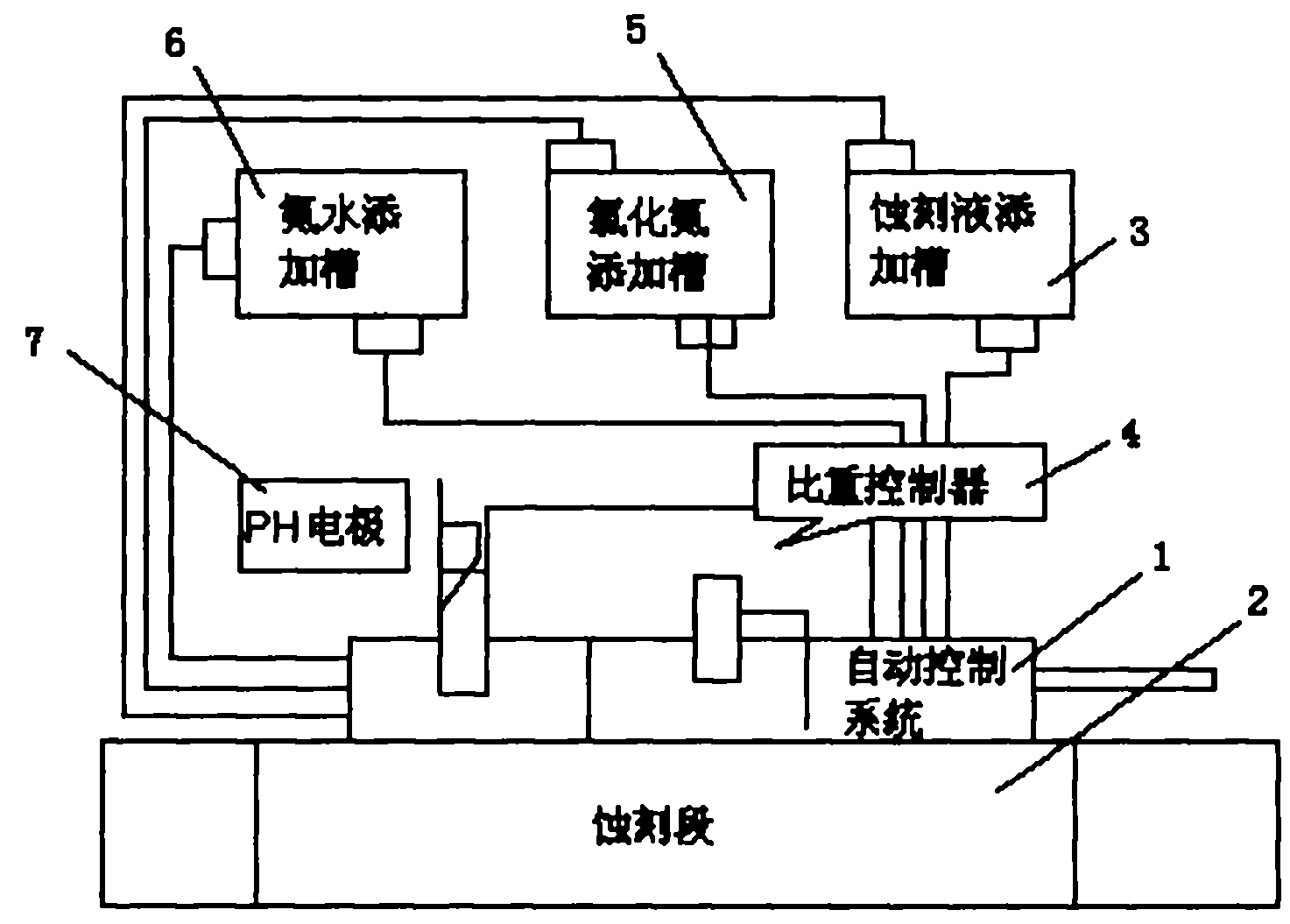

[0037] Such as figure 1 The shown alkaline etching PH value automatic control system includes an automatic control system 1 that controls the operation of the entire system, an etching solution adding tank 3 for adding etching solution to the etching section 2 and a solution specific gravity for detecting and displaying the etching section 2. Result is transmitted to the specific gravity controller 4 of automatic control system 1, also comprises the ammonium chloride addition tank 5 that is connected with etching section 2 and is used to add ammonium chloride solution to etching section 2, and is connected with etching section 2 for adding to etching section 2 Ammonia water addition tank 6 for adding ammonia solution in stage 2.

[0038] The above system also includes a pH electrode 7 arranged on the etching section 2 for detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com