Double barrier for liquefied gas storage tank and method of constructing the same

A liquefied gas storage tank and liquefied gas technology, applied in the direction of gas processing/storage, fixed capacity gas storage tank, outer wall of container structure, etc., can solve the problems of large storage tank volume, high material cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

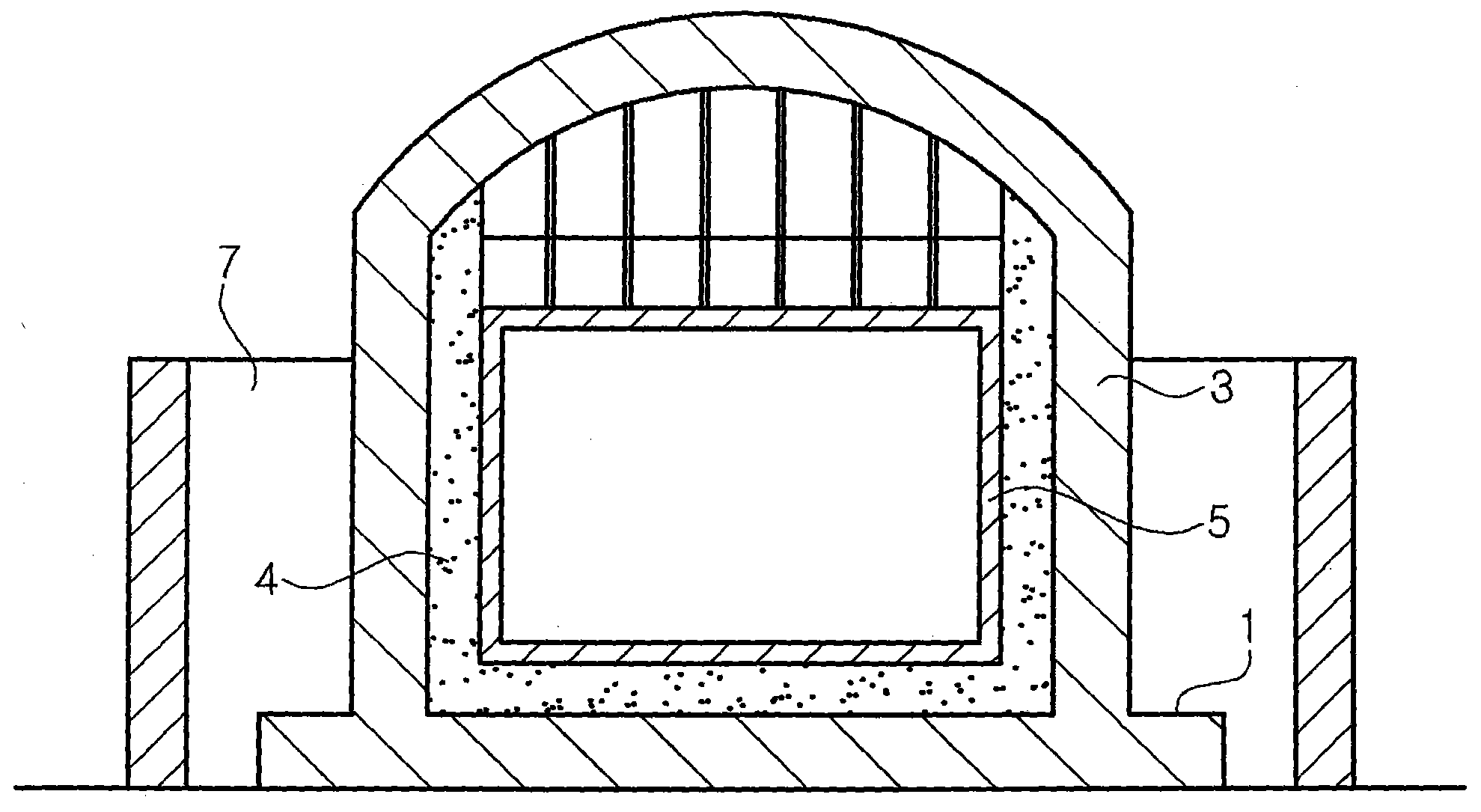

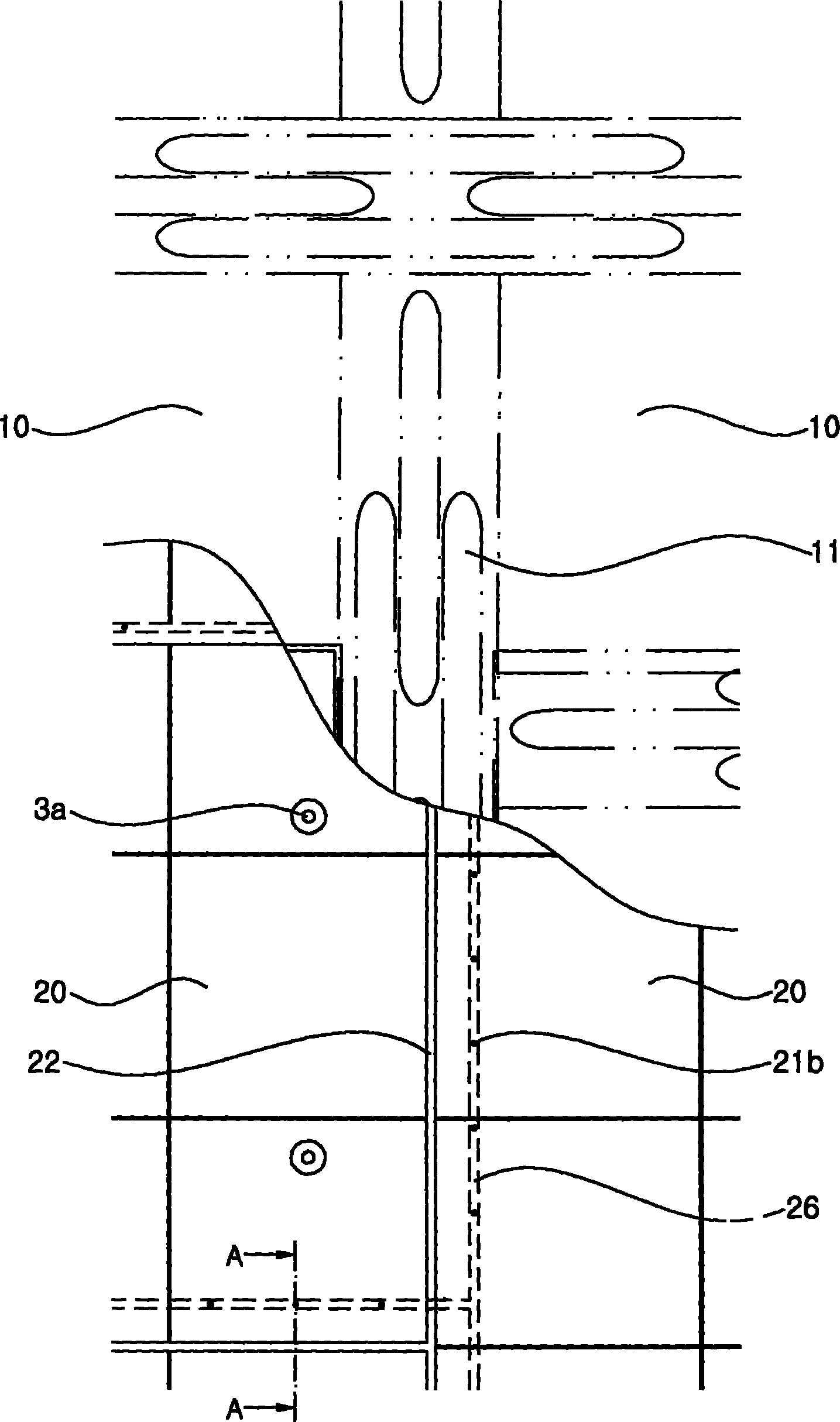

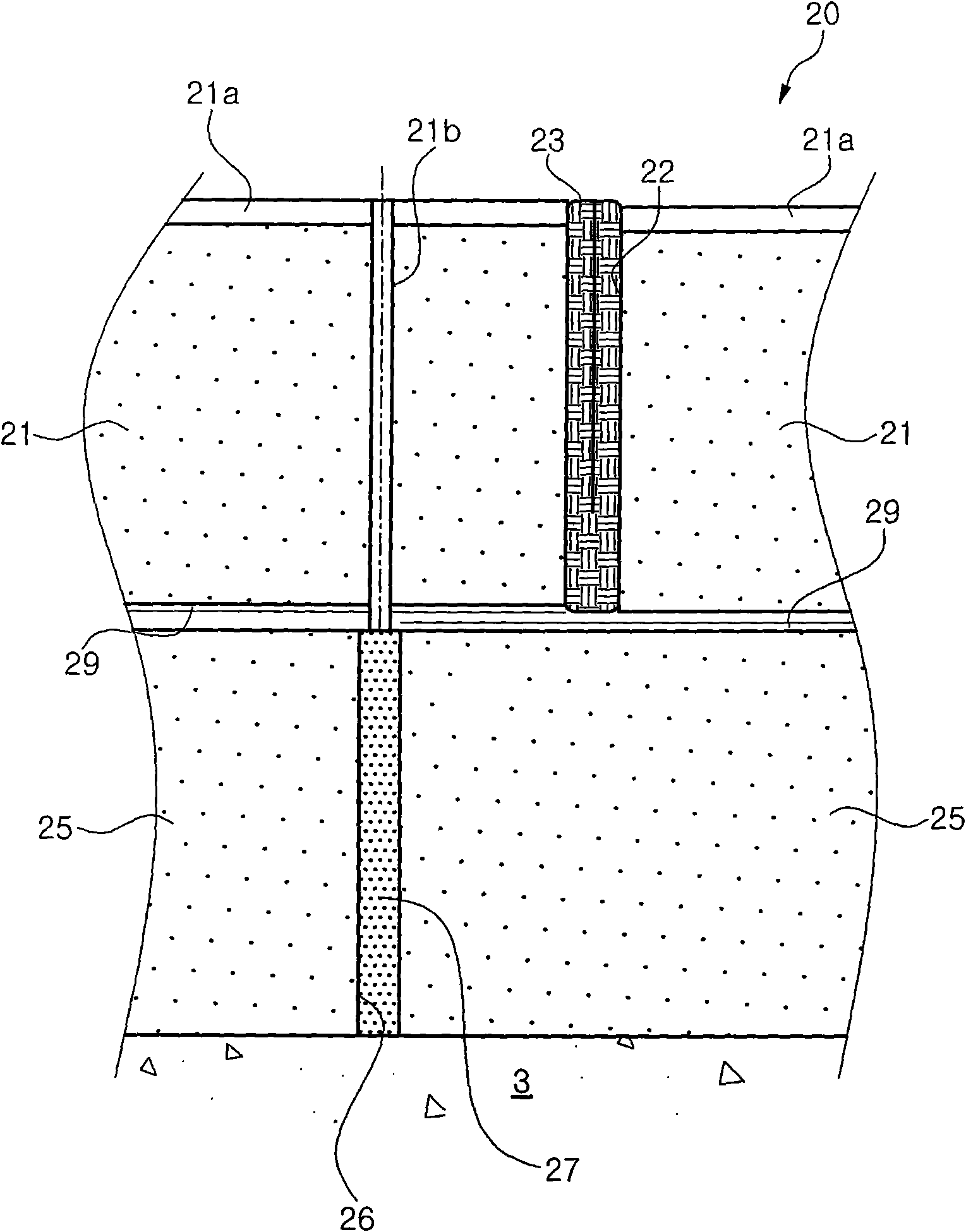

[0025] refer to figure 2 with image 3 , the double barrier for land-based liquefied gas storage tanks includes: a sealing wall 10 as a primary barrier, directly in contact with the liquefied gas stored in the storage tank; and an insulating wall 20 as a secondary barrier, arranged on the tank body 3 and the sealing wall 10 to prevent heat transfer from the outside of the tank and leakage of liquefied gas.

[0026] The sealing wall 10 (that is, the primary barrier) is continuously formed of a metal material (such as stainless steel (SUS) or the like) that can withstand the low-temperature environment inside the tank. The sealing wall 10 may be formed with corrugations 11 to absorb thermal deformation of the storage tank that occurs during receiving the liquefied gas.

[0027] The insulating wall 20 as a secondary barrier includes a primary insulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com