Core

A technology of movement and cover, applied in measuring devices, instruments, measuring fluid pressure, etc., can solve the problems of back and forth difference of instruments, tap displacement, central axis shaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above objects, features and advantages of the present invention more comprehensible, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

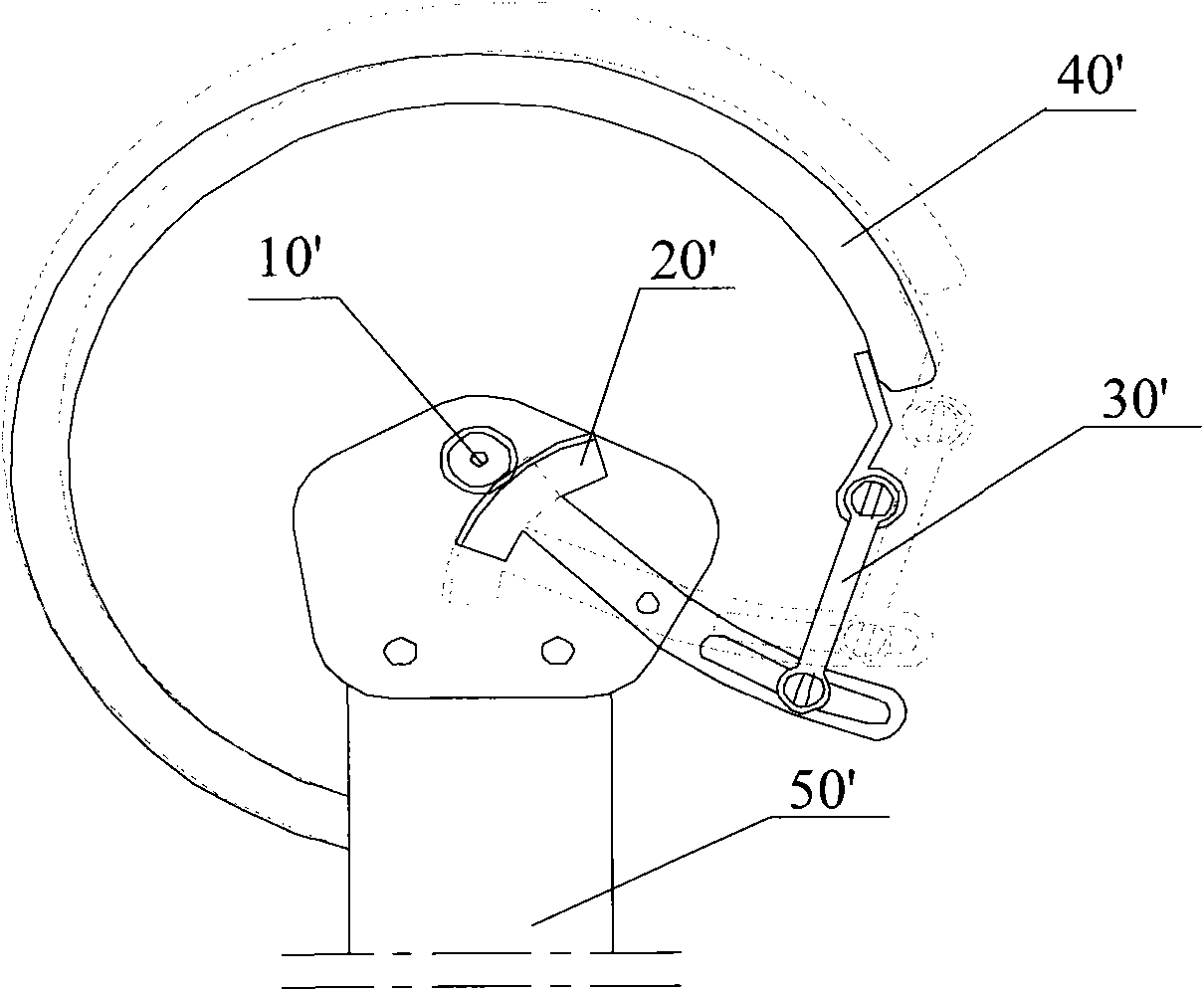

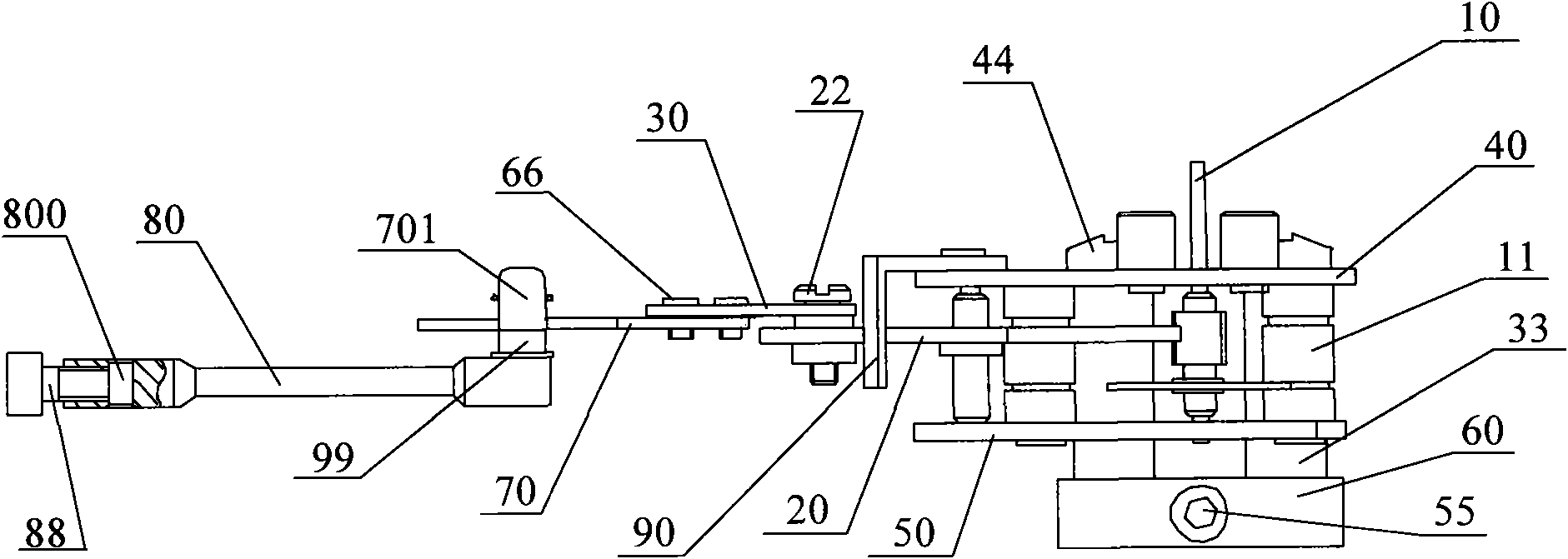

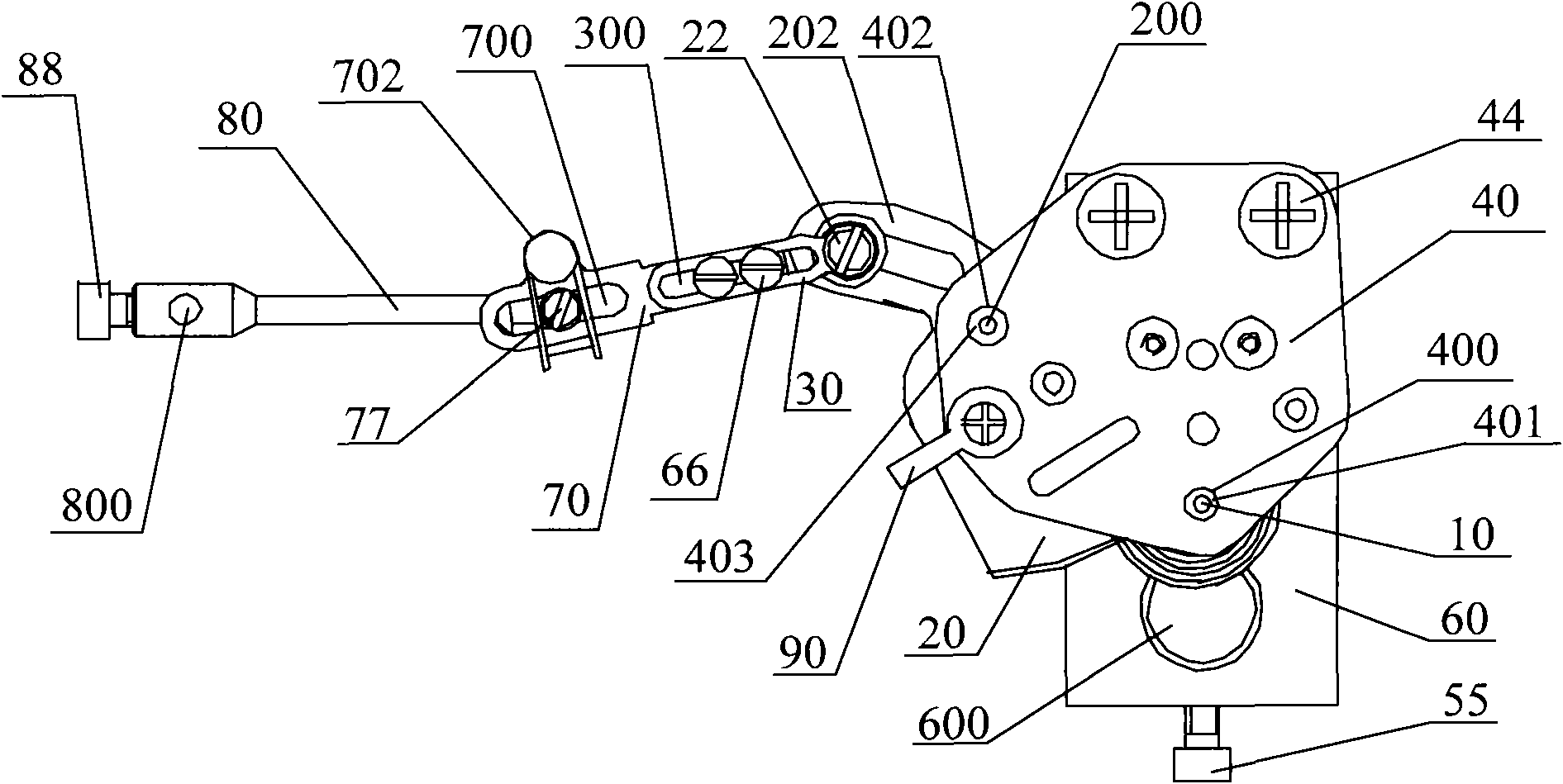

[0028] The invention provides a movement, please combine figure 2 , image 3 , the movement includes: the central axis 10, the fan teeth 20, the upper cover 40, the lower cover 50 and the connecting rod 30;

[0029] The upper cover plate 40 and the lower cover plate 50 clamp the central shaft 10 and the fan teeth 20, and the distance between the upper cover plate 40 and the lower cover plate 50 is fixed by at least two cylindrical movement bodies 11; the upper cover plate 40 The first bearing 401 is fixed in the first central axis hole 400 of the lower cover plate 50; 400 corresponds.

[0030] The upper end of the central shaft 10 passes through the first bearing 401 and cooperates with the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com