RFID (Radio Frequency Identification Device) tire electronic tag and manufacturing method thereof

A technology of electronic tags and manufacturing methods, which is applied in the fields of rubber machinery and electronic information, can solve problems such as damaged tags, achieve the effects of protecting antennas, increasing solderability, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

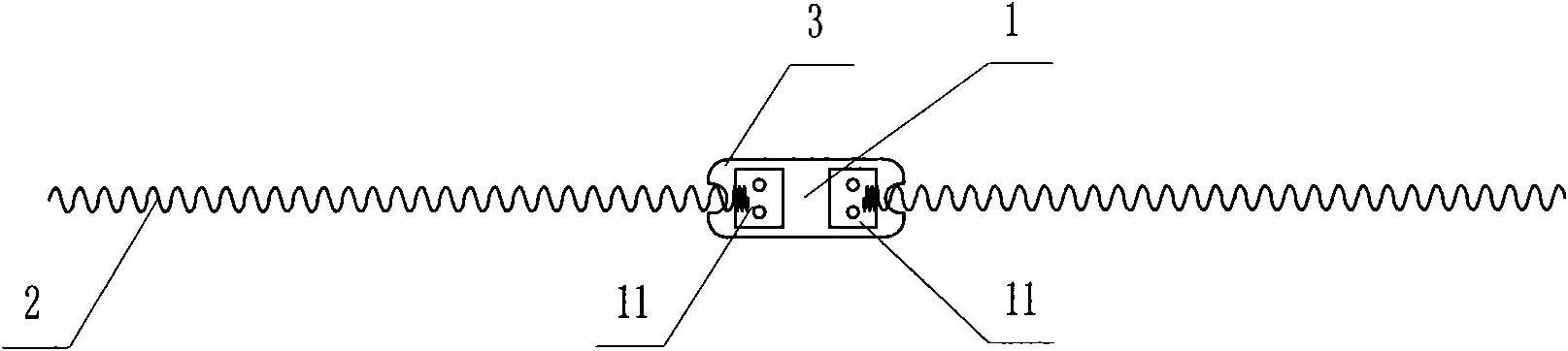

[0041] Example 1, such as Figure 1 to Figure 3 As shown, the RFID tire electronic tag mainly includes:

[0042] a radio frequency module 1 arranged on a substrate 3,

[0043] On both sides of the radio frequency module 1, a group of spring-type antennas 2 extending in a spiral shape are symmetrically connected, and the spring-type antenna 2 is a steel wire coated with brass on the outer layer.

[0044] At the end of the spring antenna 2 connected to the radio frequency module 1, springs with two pitches are fixed together.

[0045] At both ends of the radio frequency module 1 connected to the spring antenna 2, four pins 11 connected to the PAD bonding points inside the radio frequency module 1 are respectively provided.

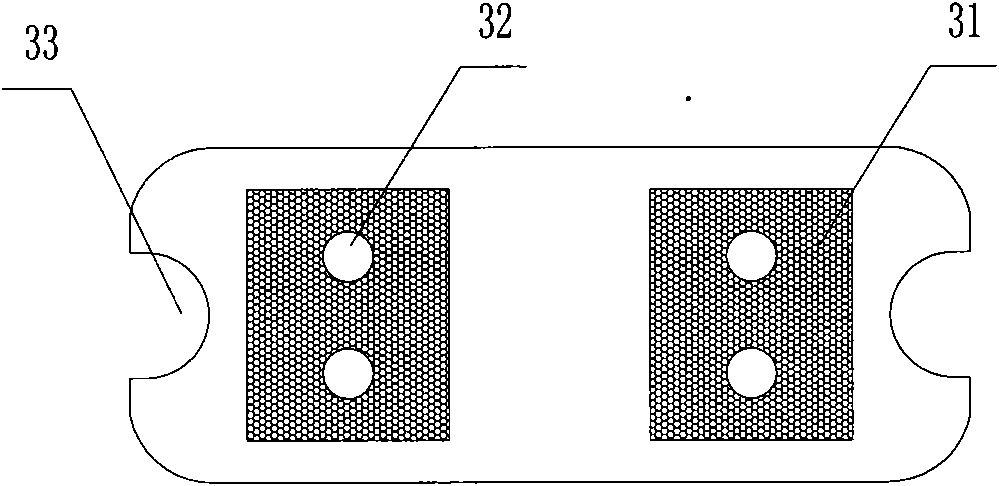

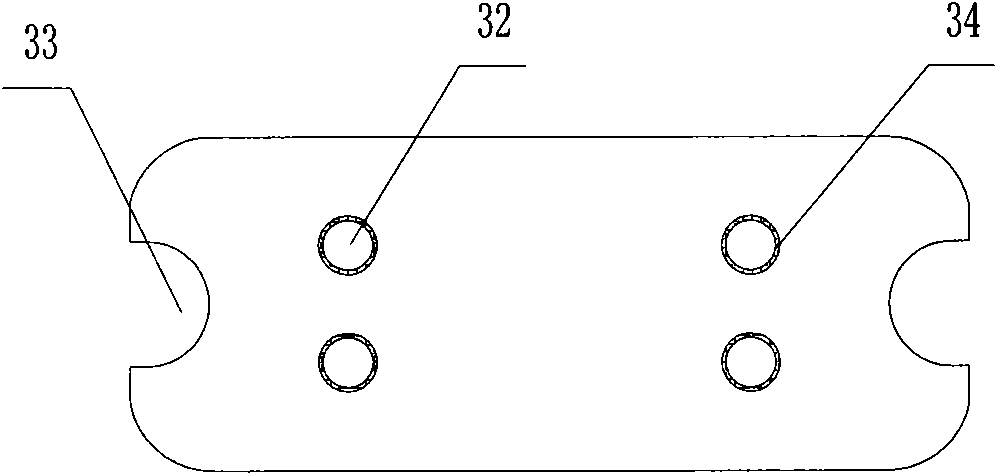

[0046] like figure 2 As shown, a copper clad layer 31 is provided on one side of the substrate 3, and the thickness of the copper clad layer 31 is 2 oz.

[0047] A through hole 32 is provided on the copper clad layer 31 , and the through hole 32 is cove...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap