A high-strength anti-corona pre-twisted suspension clamp

A hanging wire clamp and anti-halo type technology, which is applied in the direction of the cable suspension device, can solve the problems of low damage strength of the wire clamp, inconformity with resource saving, and high material consumption, so as to improve the connection strength and reliability, and save energy. Labor intensity, reliable connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

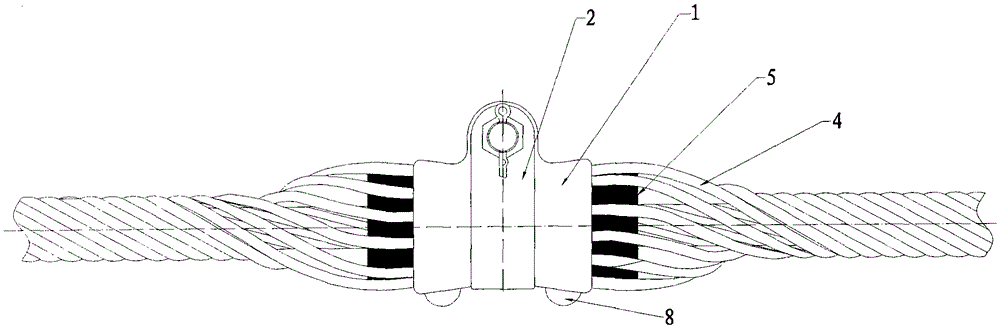

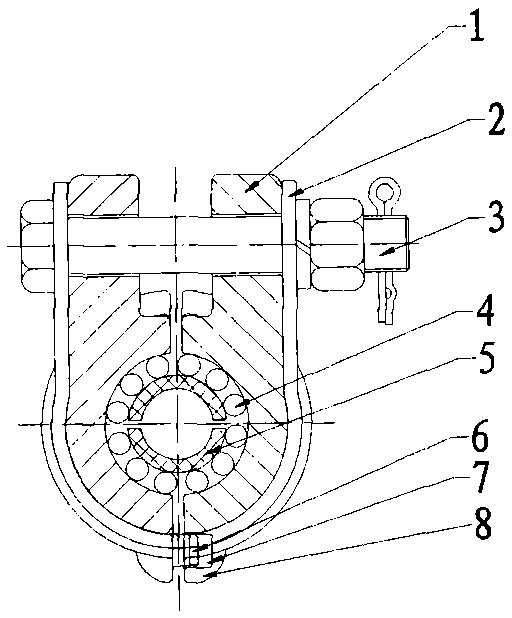

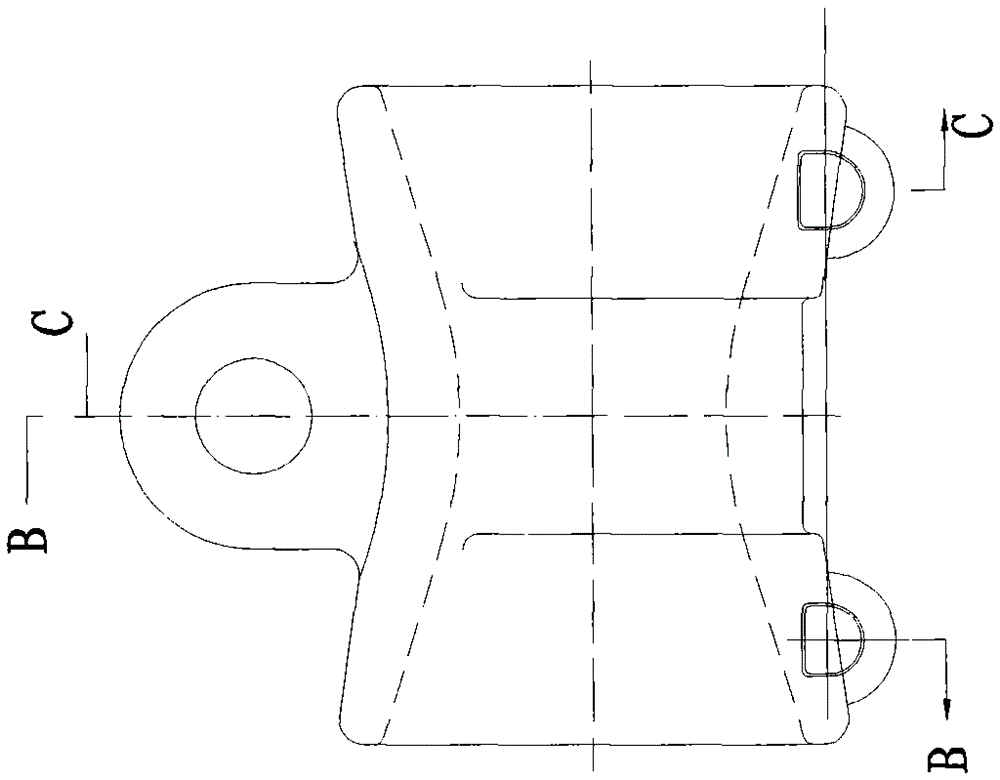

[0022] The present invention as Figure 1-9 As shown: it includes a U-shaped clamp body 1 and a fastening bolt 3. The fastening bolt 3 fastens and connects the two sides from the position of the upper lug plate of the clamp body 1. The clamp body 1 is Including the mating type of body one 11 and body two 12, there is an installation groove after the fitting between body one 11 and body two 12; it also includes the elastic clip body one and clip body two 5 of the mating type, and the Twisted wire 4; clip body 1 and clip body 2 5 are in the shape of semicircular tiles, and clip body 1 and clip body 2 5 are combined to form a wire placement groove; pre-twisted wire 4 is wound on the clip body 1 and clip body 2 5 Outer surface; the paired clip body 1 and clip body 2 5 wound with the pre-twisted wire 4 are arranged in the installation groove.

[0023] It also includes a U-shaped hoop 2, the upper sides of the U-shaped hoop 2 are provided with through holes for passing through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com