Linear Suspension and Shock Absorption Device for Wheeled Mobile Robot Chassis

A mobile robot, suspension and shock absorption technology, applied in the field of robotics, can solve the problems of high cost and complicated electric control, and achieve the effect of low cost, simple structure and sufficient grip performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

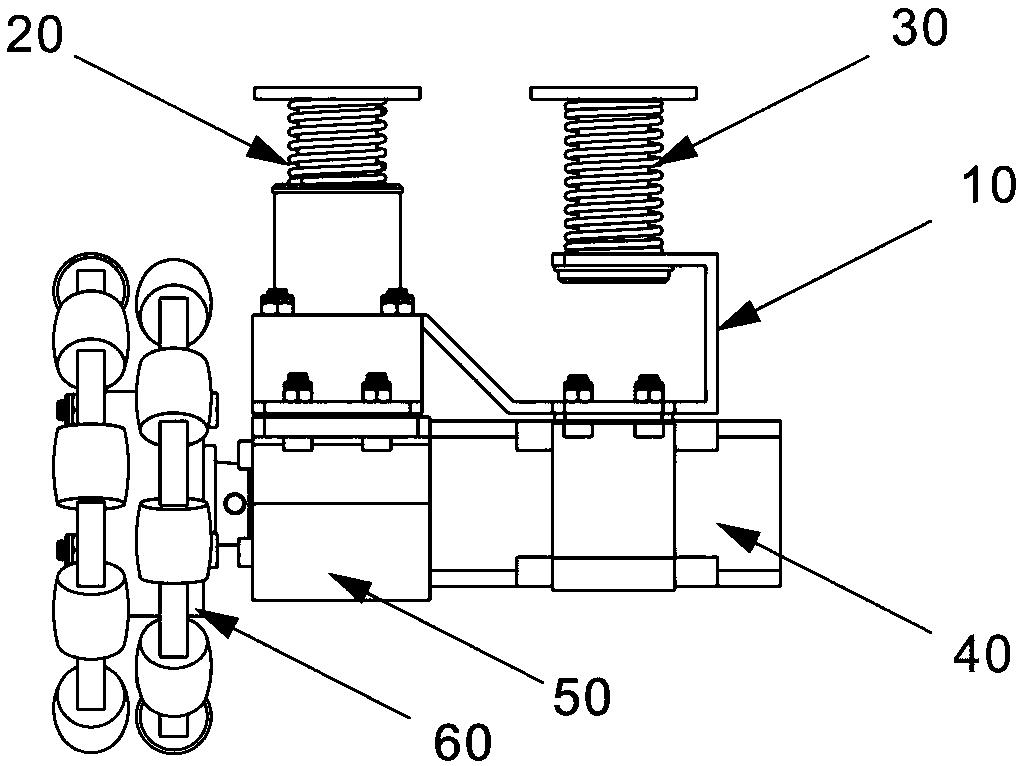

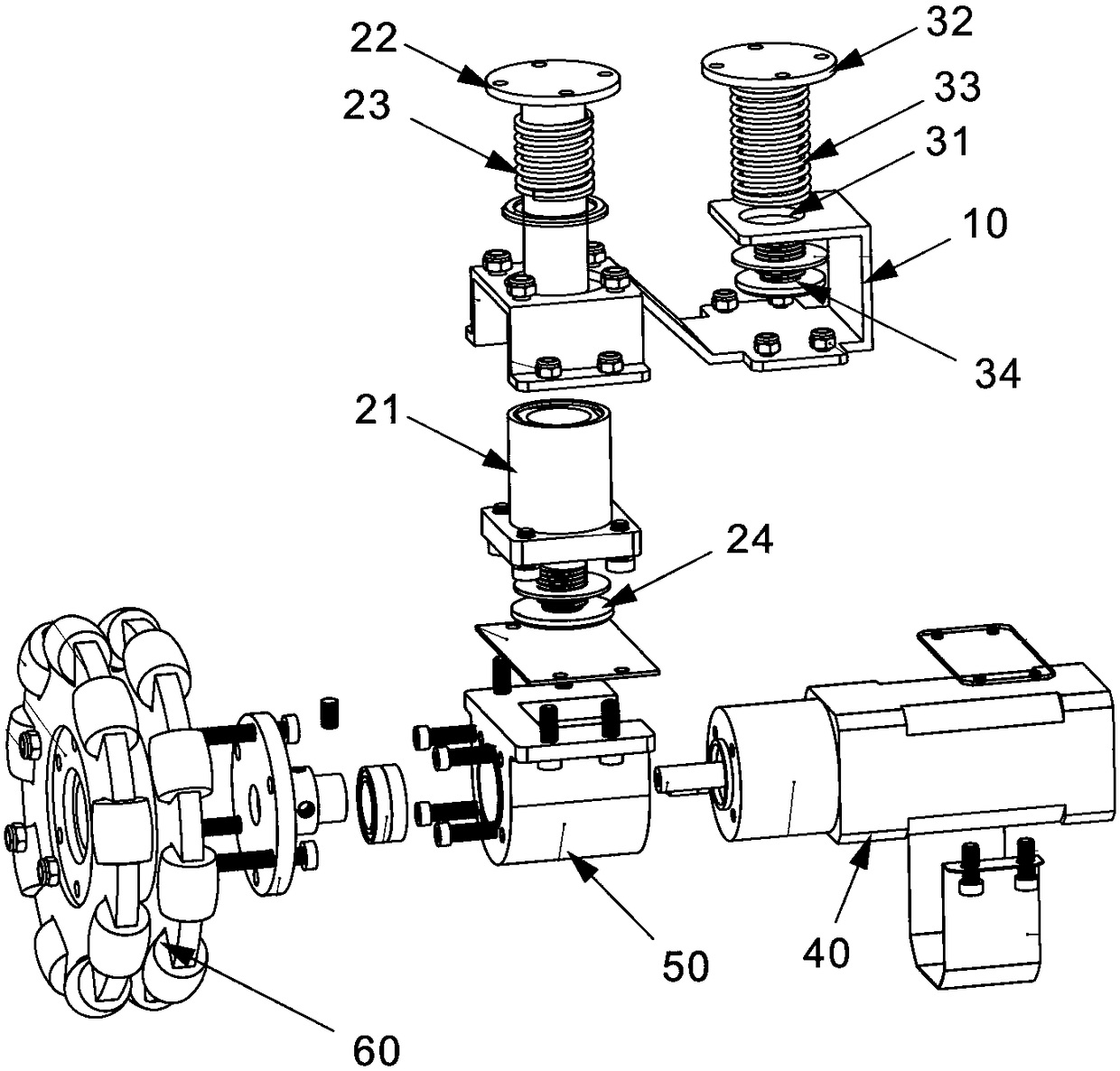

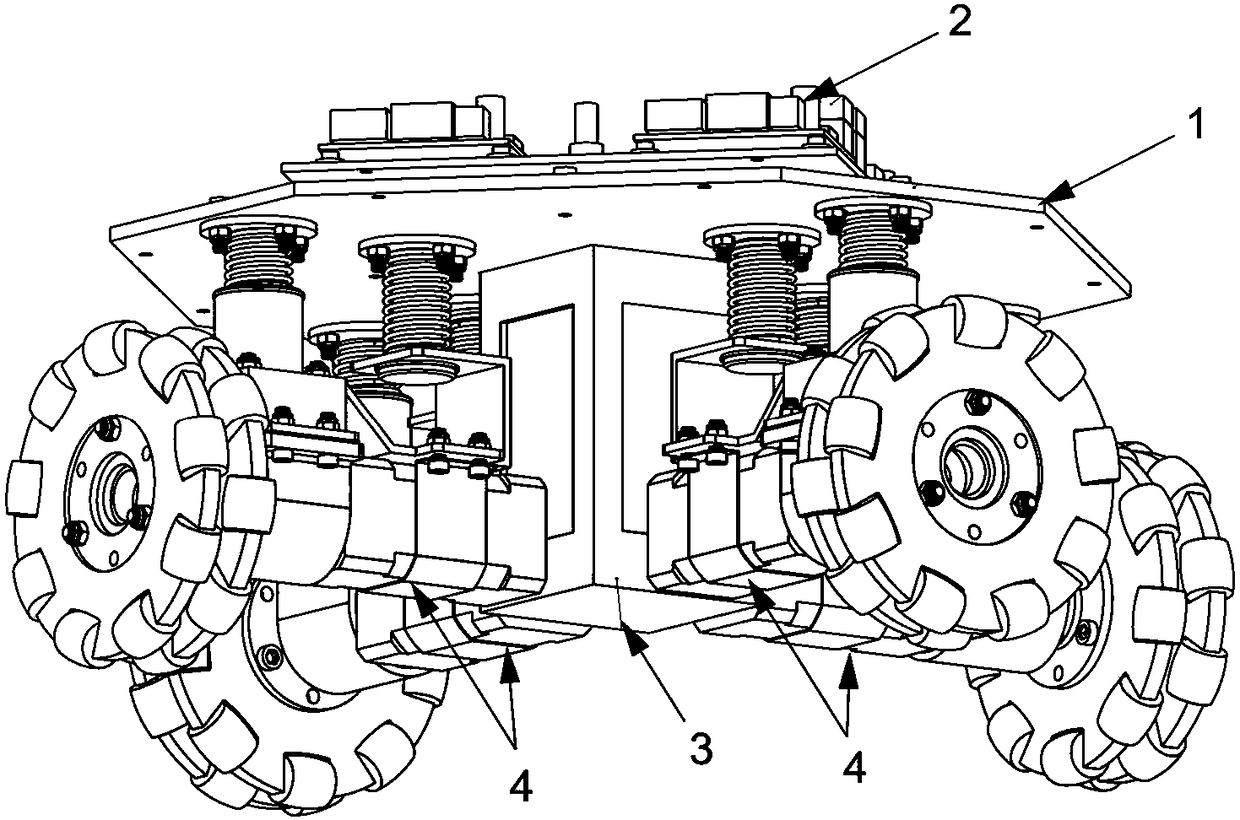

[0019] Such as figure 1 As shown, the linear suspension shock absorber of the wheeled mobile robot chassis includes a suspension shock absorber assembly for connecting the robot chassis, and a motion assembly connected to the bottom of the suspension shock absorber assembly, wherein:

[0020] Described suspension damping assembly comprises support 10, motion main shaft 20 and motion sub-shaft 30, has elasticity between support two ends, and motion main shaft 20 and motion sub-shaft 30 are respectively arranged at support 10 two ends, and motion main shaft 20 and motion sub-shaft The top of 30 is connected with robot chassis (not shown in the figure), and the bottom of motion main shaft 20 and motion sub-shaft 30 keeps elastic contact with support 10 top surface;

[0021] The motion assembly includes a motor 40, a motor base 50 and a wheel 60 connected in sequence, the motor 40 and the motor base 50 are connected to the bottom surface of the support 10, the motor 40 is fixed be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com