Stripping deck

A technology for decks and partitions, applied in the field of stripping decks, can solve problems such as the inability to reuse resources, and achieve the effect of preventing collapse and improving the bonding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described below with reference to the drawings.

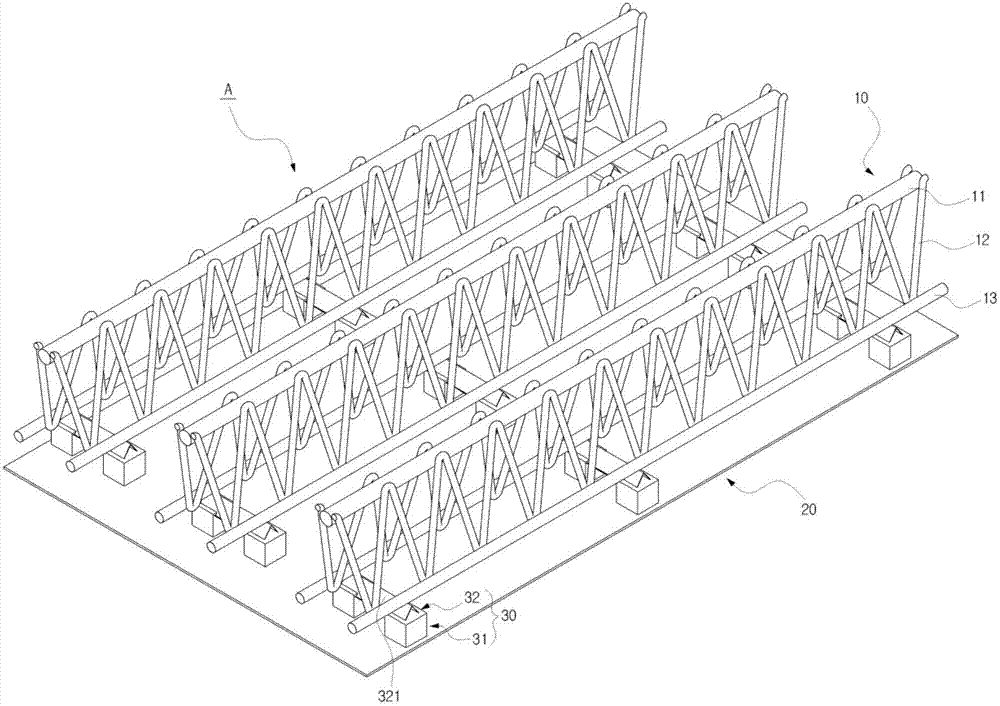

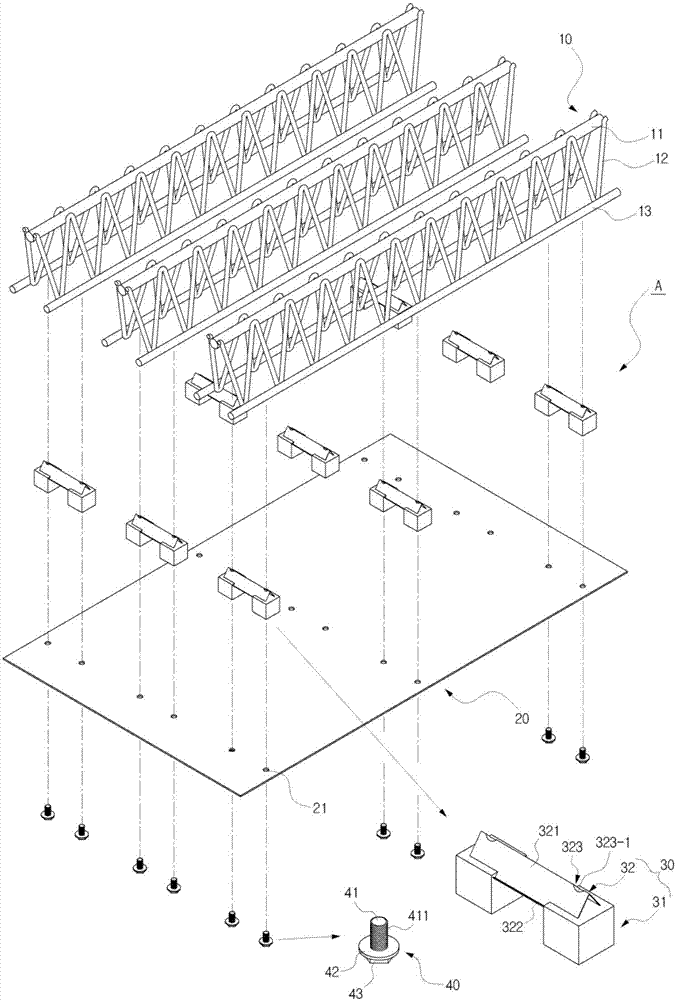

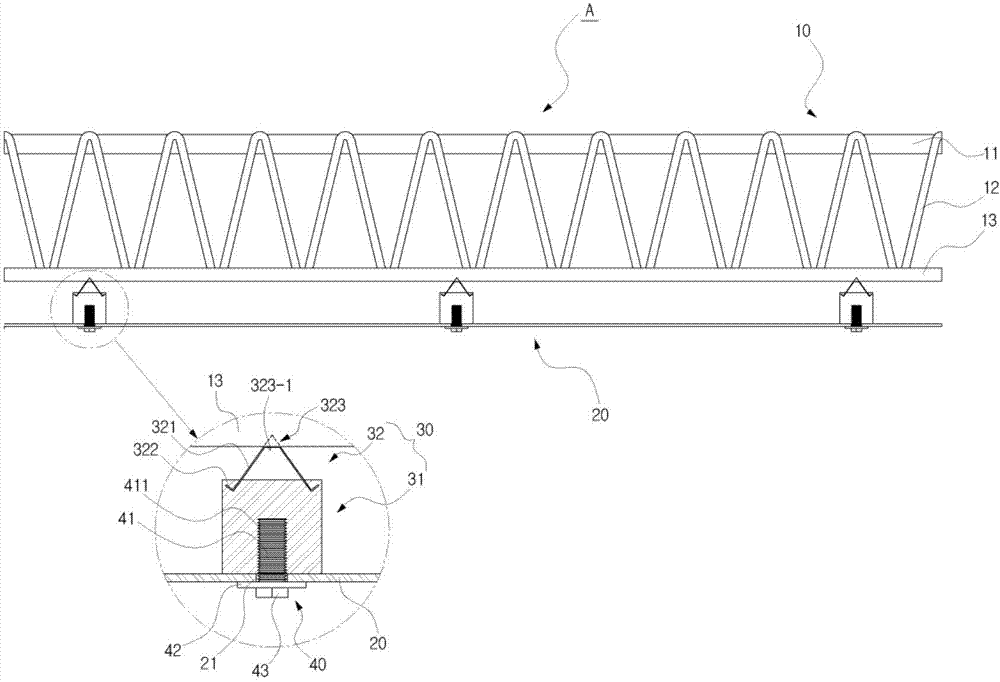

[0025] Such as Figure 1 to Figure 4 As shown, the stripped deck A according to the present invention includes frame beams 10 , formwork 20 and partitions 30 . And the above-mentioned partition plate 30 is joined between the above-mentioned frame beam 10 and the formwork 20, so that the formwork 20 is detachably constituted.

[0026] Here, the above-mentioned frame beams 10 are embedded in the panel which is cured after pouring concrete, and have a function of resisting tensile load and compressive load acting on the panel. And the two sides of the upper chord 11 are connected with the upper inner side of the upper end of the lattice frame 12 which is smaller in diameter than the upper chord 11 and bent into a zigzag shape, and connected by welding.

[0027] The above-mentioned lattice frame 12 is formed so that the lower end expands, in other words, it is formed into the sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com