Power equipment and high-temperature self-protection method thereof

A power equipment, high temperature technology, applied in the field of automatic adjustment of the internal working temperature environment of power equipment, can solve the problems of reducing the service life of fans and reducing the service life of power equipment, affecting the performance of electronic products, affecting the working performance of electronic components, etc. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

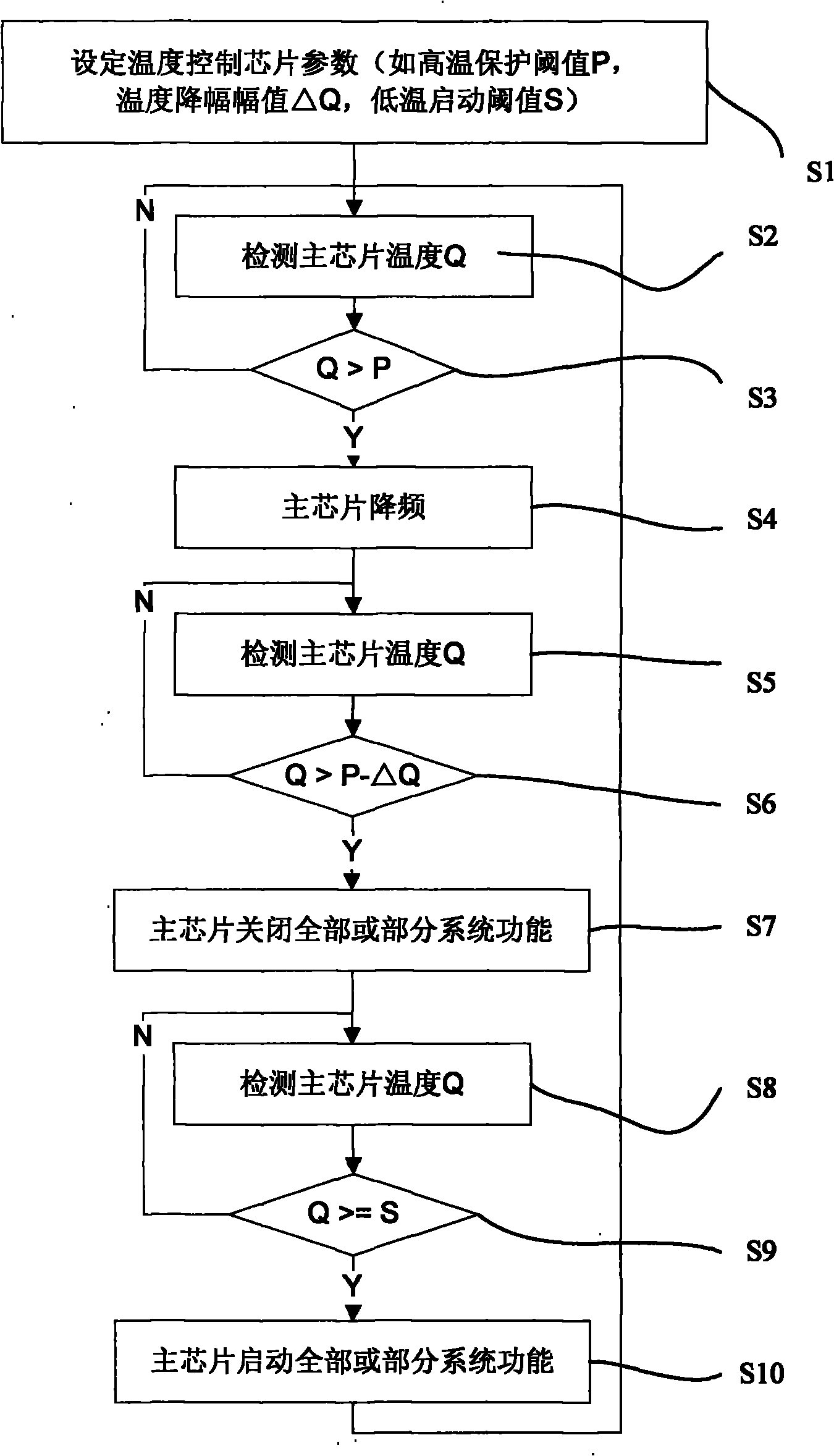

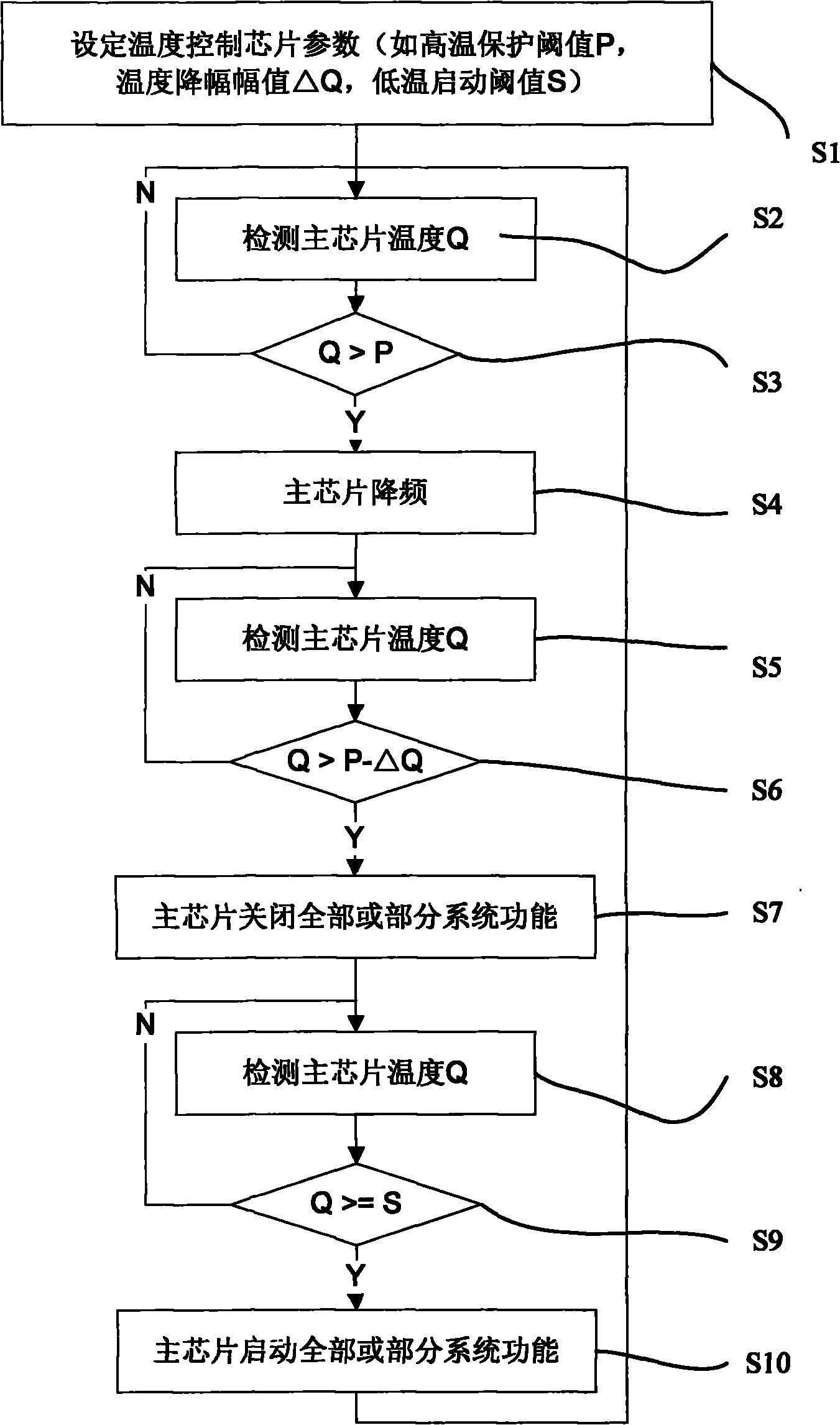

[0016] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

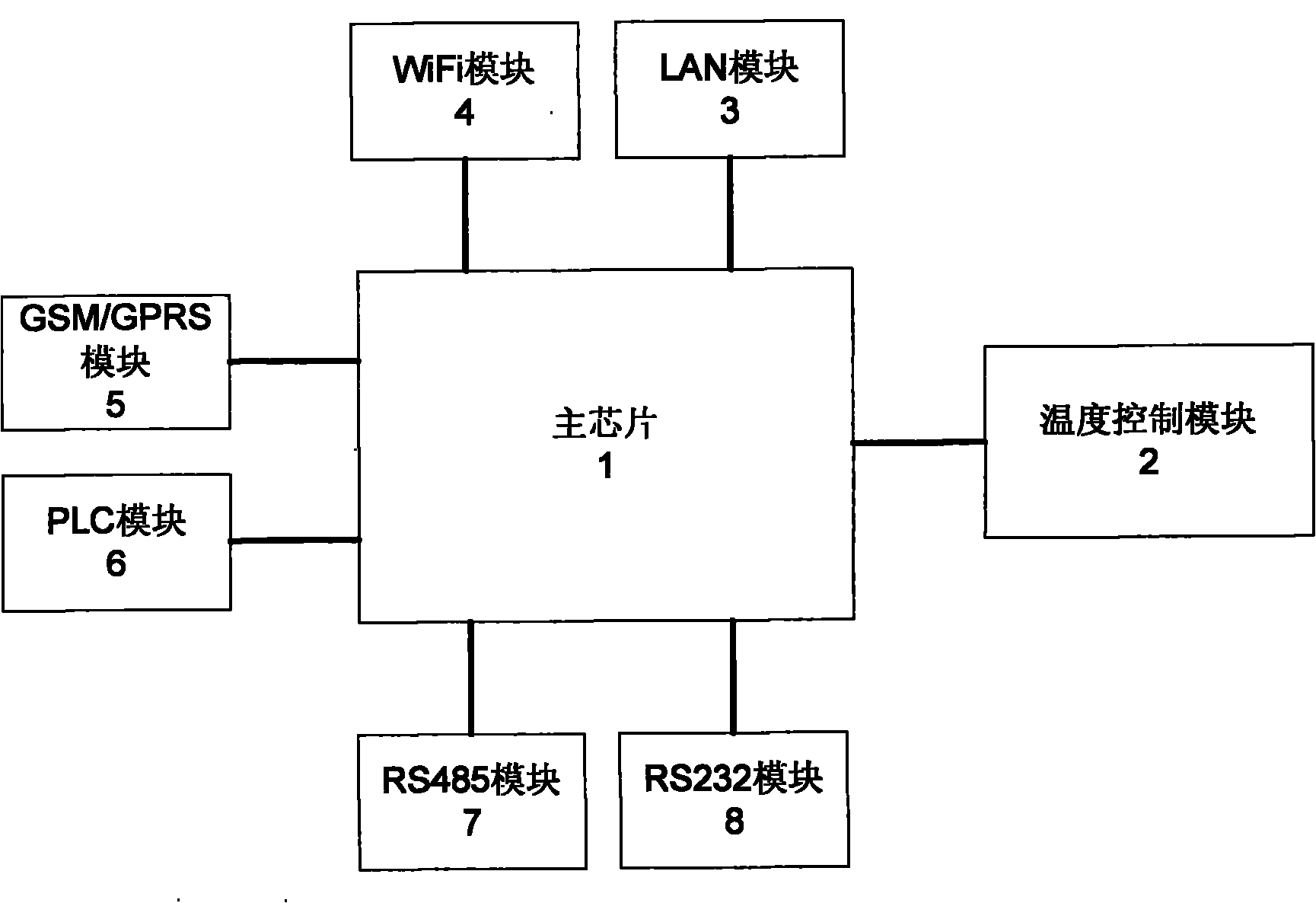

[0017] The block diagram of the circuit structure of the power equipment of the present invention, as figure 1 shown, including:

[0018] The main chip 1 is the central processing unit of the power equipment;

[0019] The temperature control module 2 is a temperature control module of the power equipment, responsible for monitoring and detecting the temperature of the main chip 1 , and sending the detection result to the main chip 1 . When the detected temperature is greater than the temperature protection threshold, the main chip 1 is notified to reduce the frequency; when the temperature of the main chip 1 is still not lowered to the expected temperature range after the frequency reduction, the main chip 1 is notified to shut down the system. When the detecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com