Method and system for processing graphs

A processing method and graphic technology, applied in chemical/electrolytic methods to remove conductive materials, printed circuits, electrical components, etc., can solve the problems of complex implementation, high process requirements, poor dry film analysis, etc., and achieve high accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

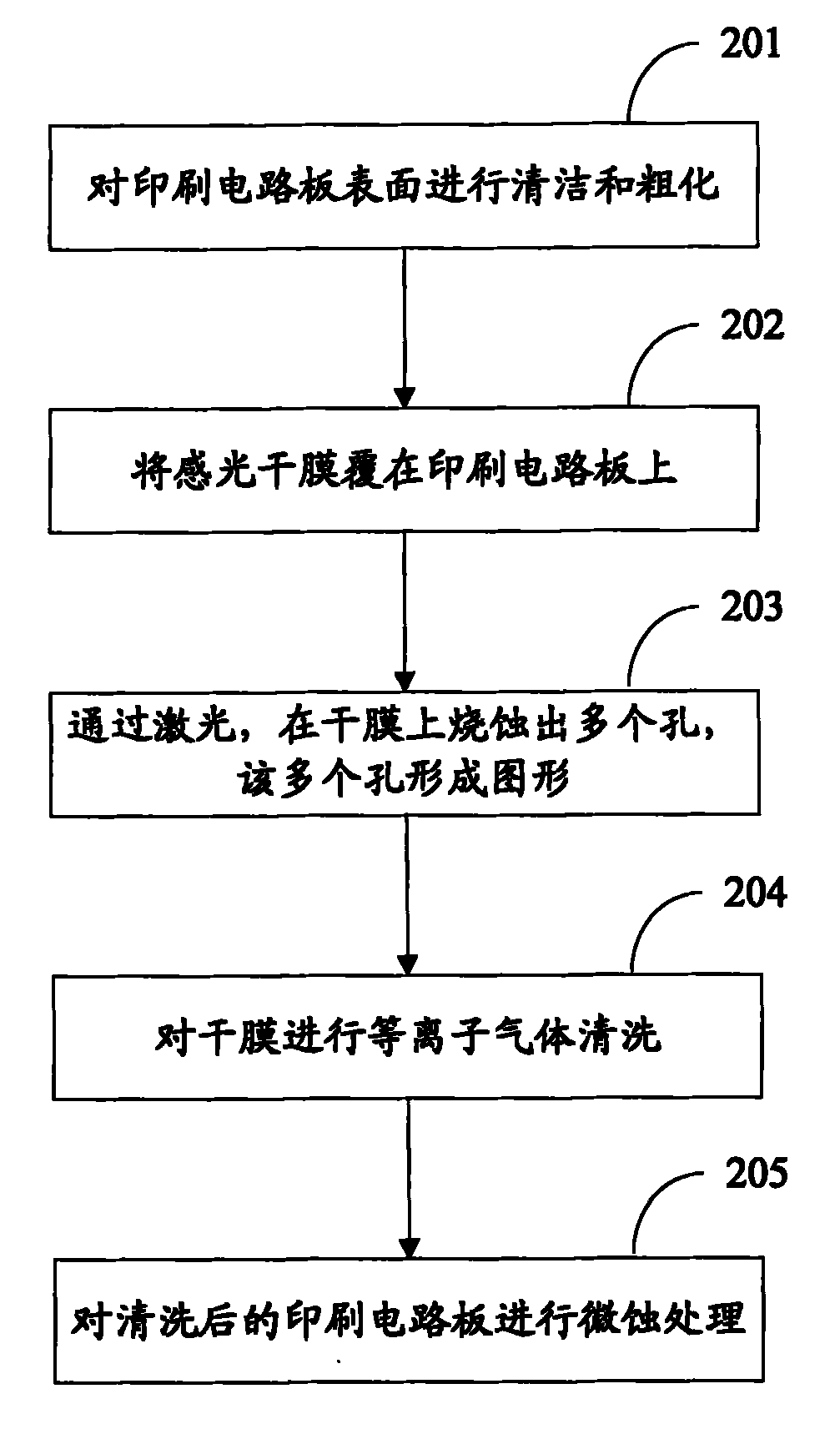

[0028] In the embodiment of the present invention, a plurality of holes are ablated on the dry film by means of laser drilling, and the plurality of holes form a pattern, which realizes pattern processing and solves the problems caused by exposure and development. Moreover, in the embodiment of the present invention, only the dry film is ablated during hole burning, and the printed circuit board under the photosensitive dry film is not ablated.

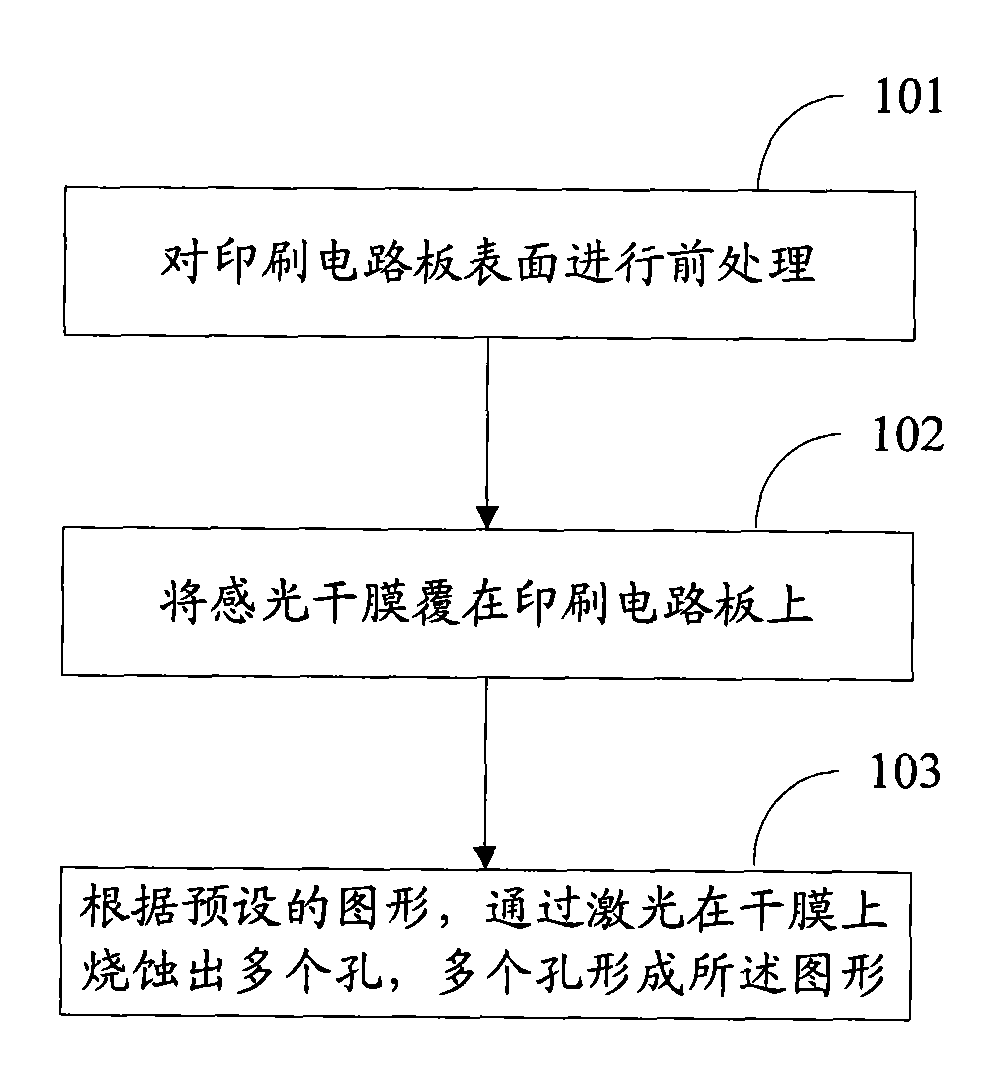

[0029] see figure 1 , the main process flow of graphics processing in this embodiment is as follows:

[0030] Step 101: Perform pretreatment on the surface of the printed circuit board. Specifically, the surface of the printed circuit board is cleaned and roughened.

[0031] Step 102: Covering the dry film on the printed circuit board. The dry film in this embodiment can be a photosensitive dry film.

[0032] Step 103: According to the preset pattern, ablate a plurality of holes on the dry film by laser, so that the plurality of h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com