Buckle, radiation device using buckle, and electronic device

A technology for electronic devices and heat sinks, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of unfavorable resource reuse, cumbersome and time-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

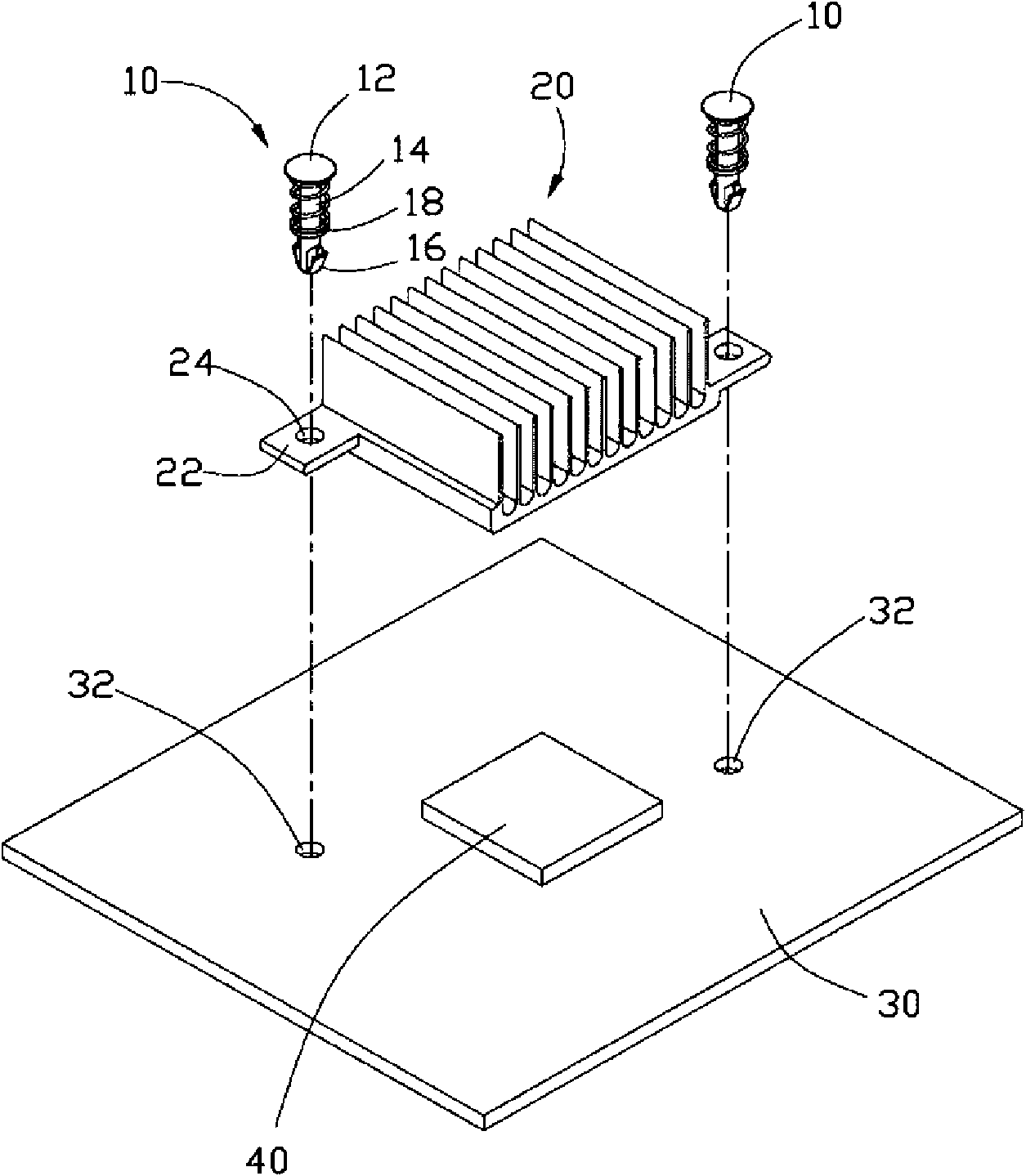

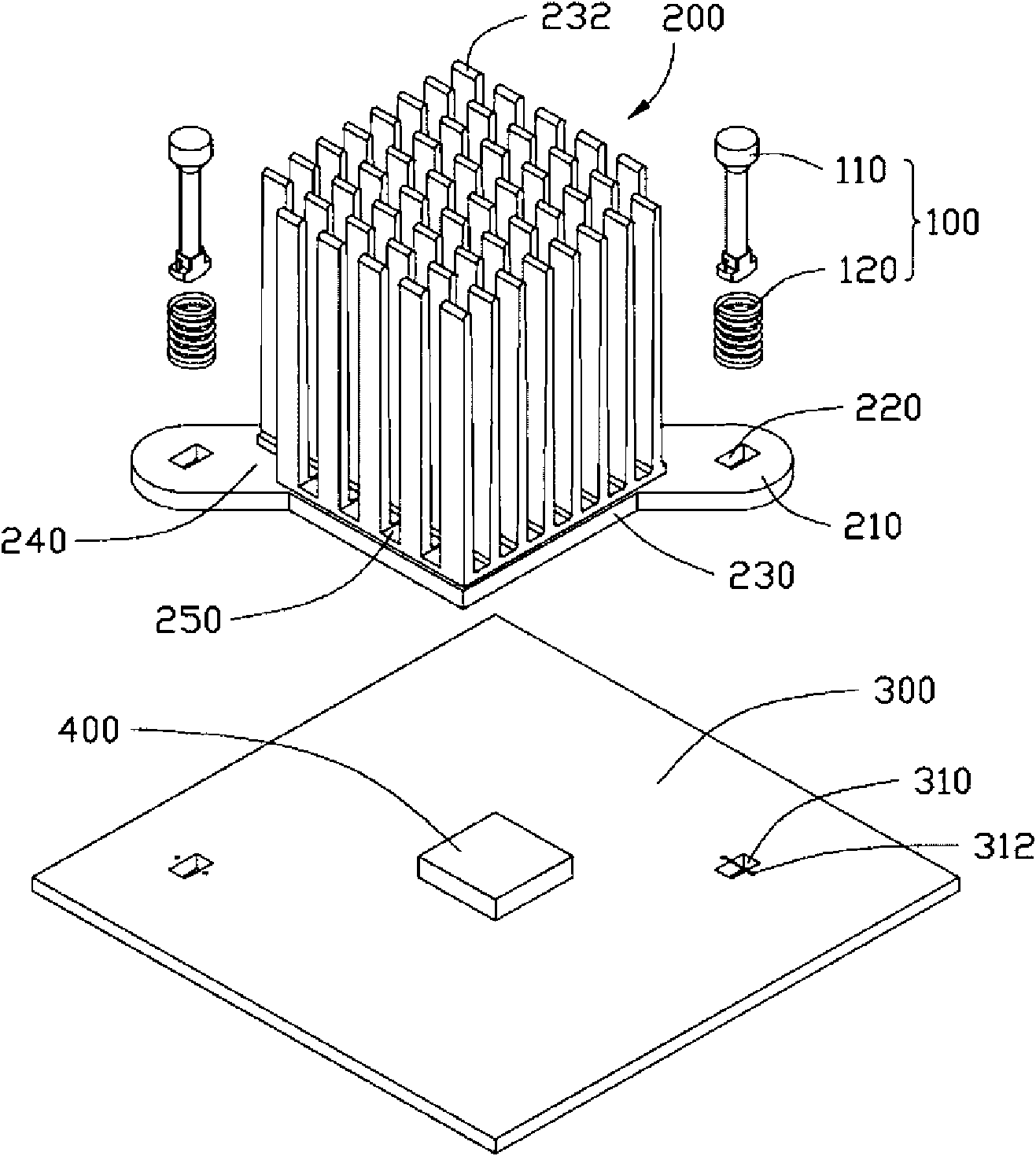

[0016] see figure 2 , the electronic device in some embodiments of the present invention includes a carrier board 300 and a heat sink mounted on the carrier board 300 . The cooling device is used to dissipate the heat generated by an electronic component 400 (for example, a computer CPU) mounted on the carrier board 300 . The heat dissipation device includes a heat sink 200 and two fasteners 100 for fixing the heat sink 200 on the electronic component 400 .

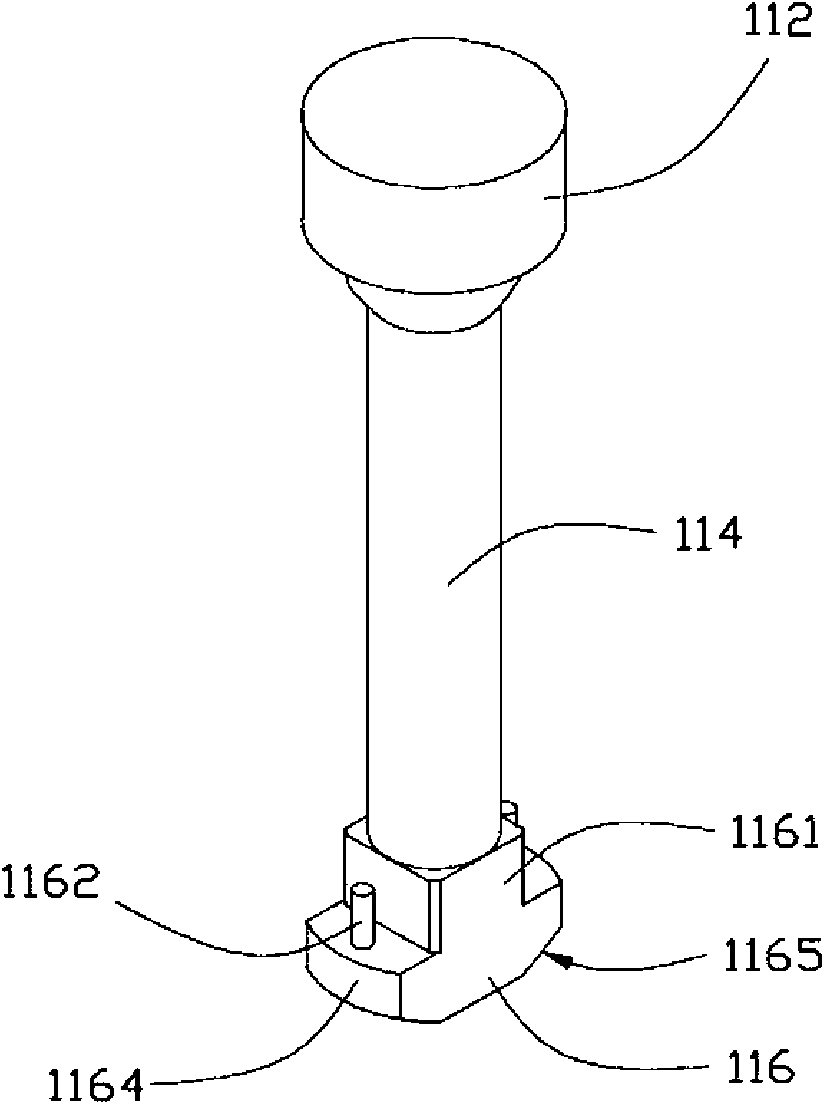

[0017] Please also see image 3 , each of the above-mentioned fasteners 100 includes a fastener 110 and an elastic element mounted on the fastener 110 . In some embodiments, the elastic element is a spring 120 . The fastener 110 is integrally made of plastic material or other materials, and includes a connecting rod 114 , an operating portion 112 at the top of the connecting rod 114 , and a fastening portion 116 at the bottom of the connecting rod 114 . The elastic element is sheathed on the connecting rod 114 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com