Method for producing a fuel tank for a motor vehicle and fuel tank for a motor vehicle

A fuel tank, motor vehicle technology, applied in the layout, application, power plant, etc. combined with the fuel supply of the internal combustion engine, can solve the problems of shrinkage bending and manufacturing tolerance changes, difficulty in assembling refueling and running the exhaust device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

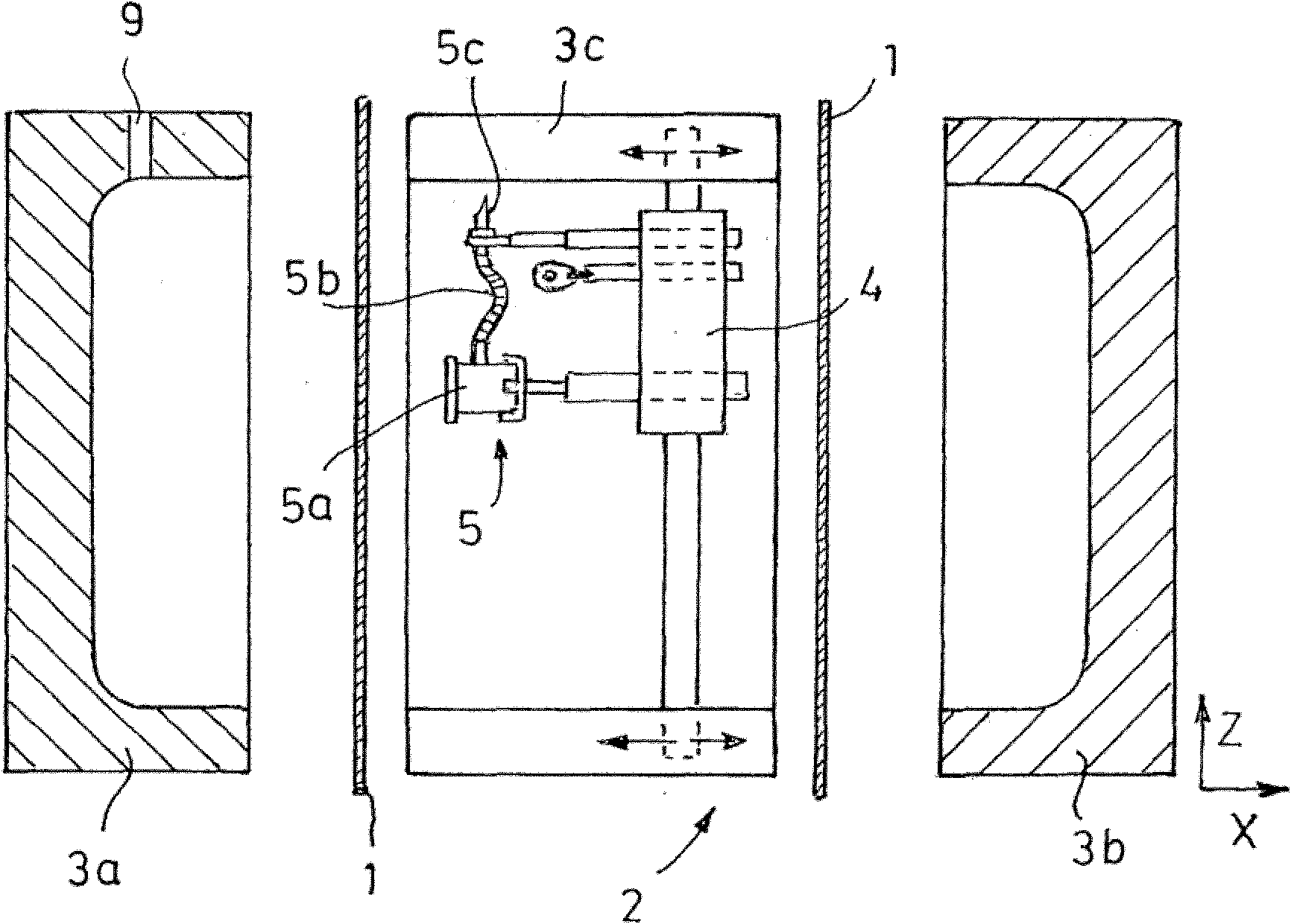

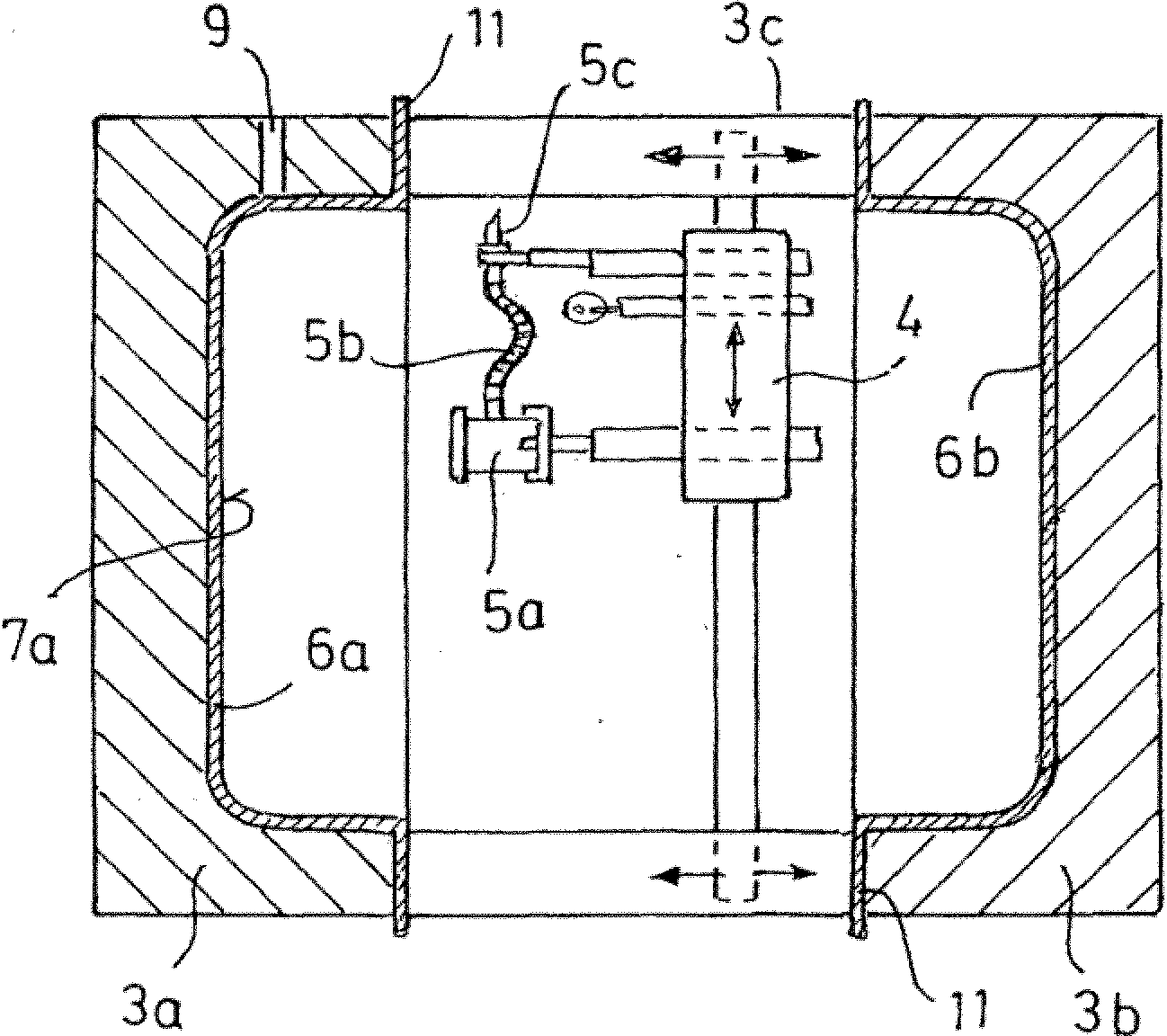

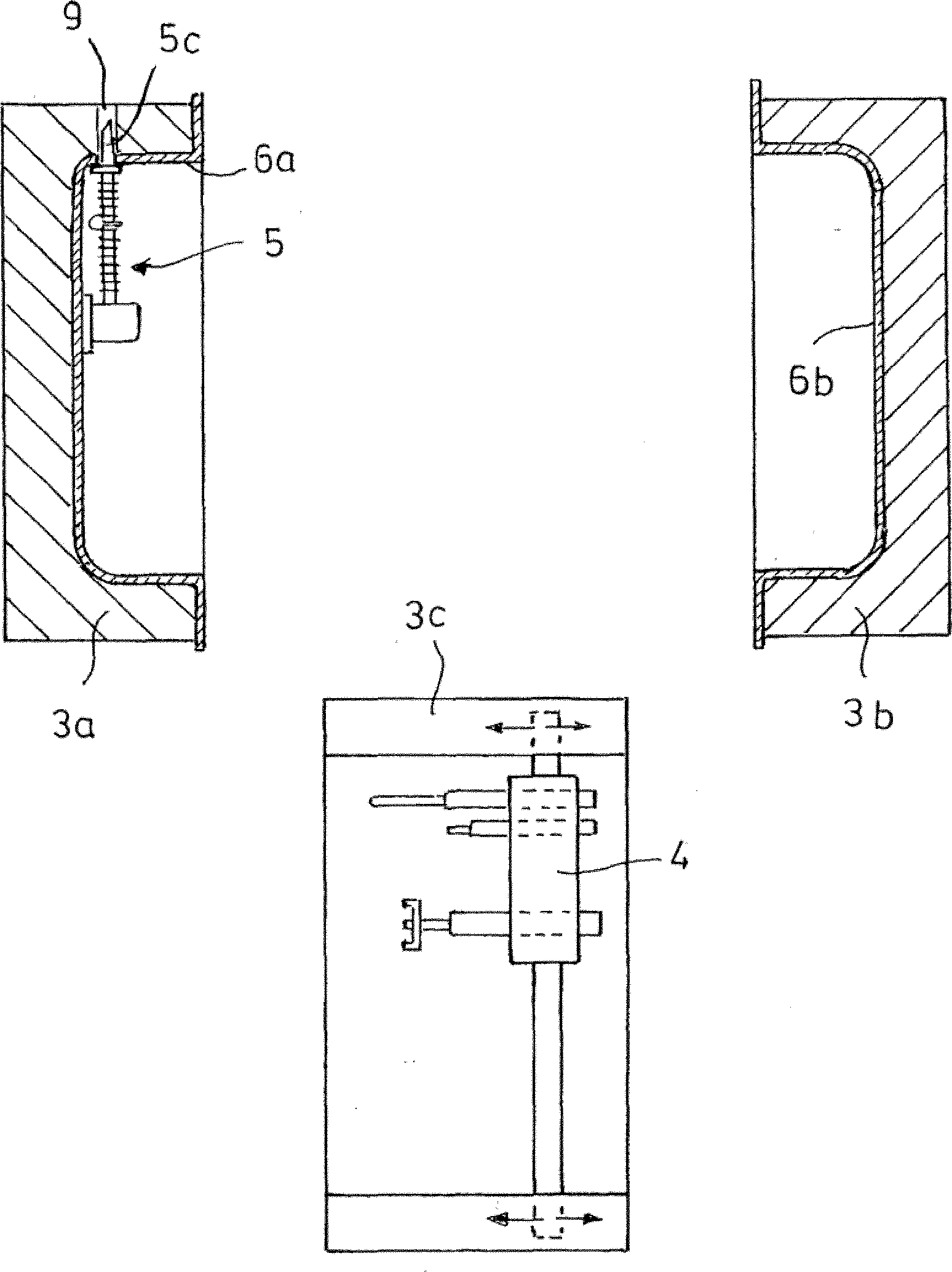

[0037] The method according to the invention essentially firstly Figures 1 to 3 Explanation. The method consists in extruding two web-shaped or sheet-shaped preforms 1 from a thermoplastic material by means of one or more extruders (not shown) arranged above the die 2 . These preforms 1 can be obtained here by cutting out tube-like preforms or alternatively extruded from wide-slit nozzles. These preforms 1 are basically constituted by a coextrusion of six layers formed of polyethylene, a regrind layer (scrap layer), an adhesive layer and an EVOH barrier layer for hydrocarbons. The layer structure of such extrudates is basically known. The preforms can be extruded directly above the mold in the direction of gravity, alternatively they can be removed from the extrusion head by means of a handling device and transferred into the mold 2 .

[0038] Die 2 in Figures 1 to 3 is shown partially cut away in top view. These molds comprise two outer molds 3a, 3b and an intermediate m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com