Method for processing substrate of mother board

A processing method and substrate technology, applied in stone processing equipment, stone processing tools, manufacturing tools, etc., can solve problems such as difficult marking grooves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

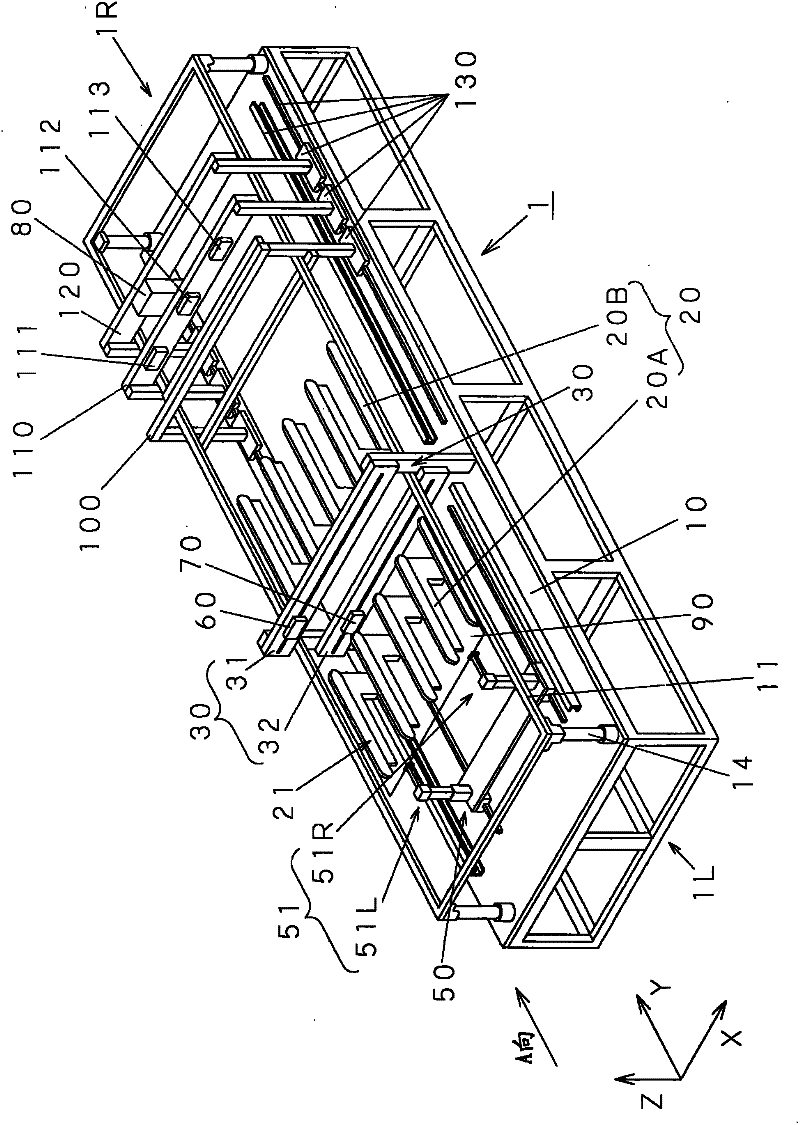

[0088] Embodiments of the substrate processing method of the present invention will be described with reference to the drawings. The substrate processing method described below is a method used in the manufacturing process of a liquid crystal display panel, specifically, a method used in a substrate processing system for dividing a unit display panel as a liquid crystal display panel from a mother board and remove them one by one.

[0089] (substrate processing system)

[0090] First, the overall configuration of a substrate processing system used for carrying out the substrate processing method of the present invention will be described.

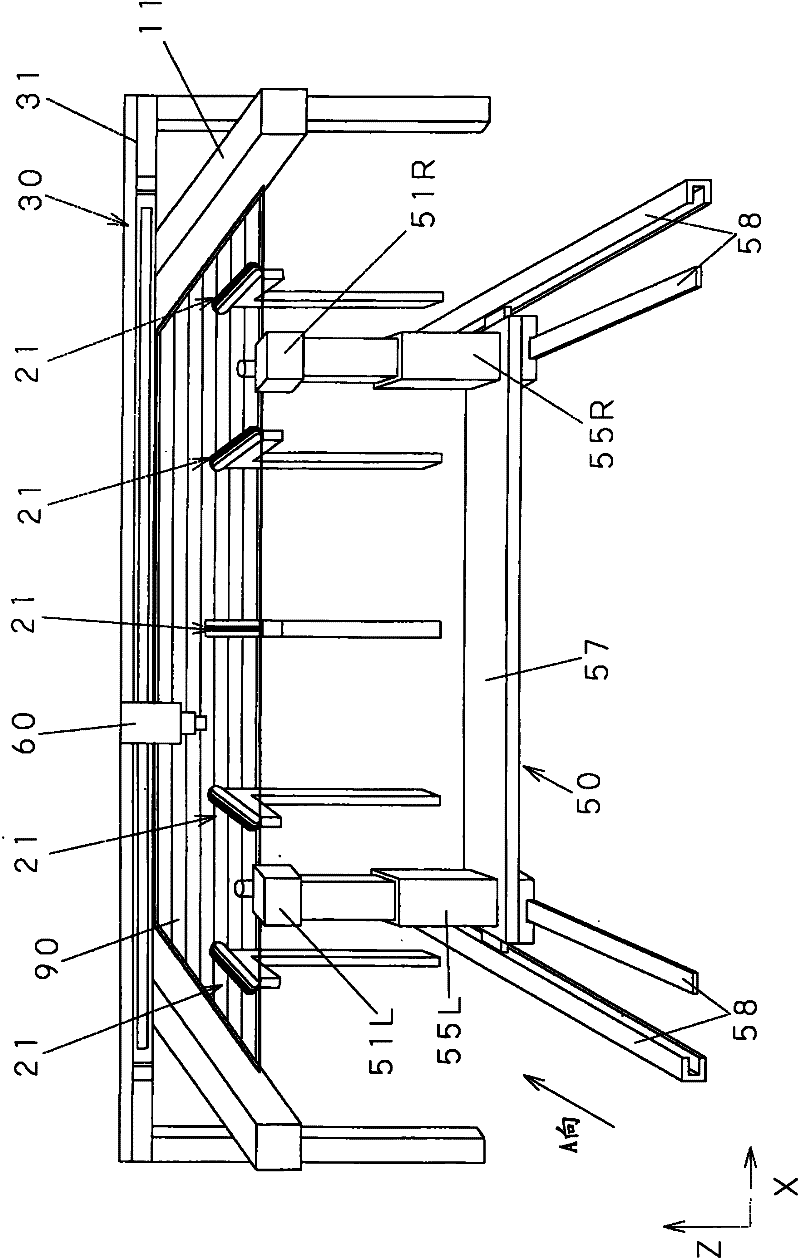

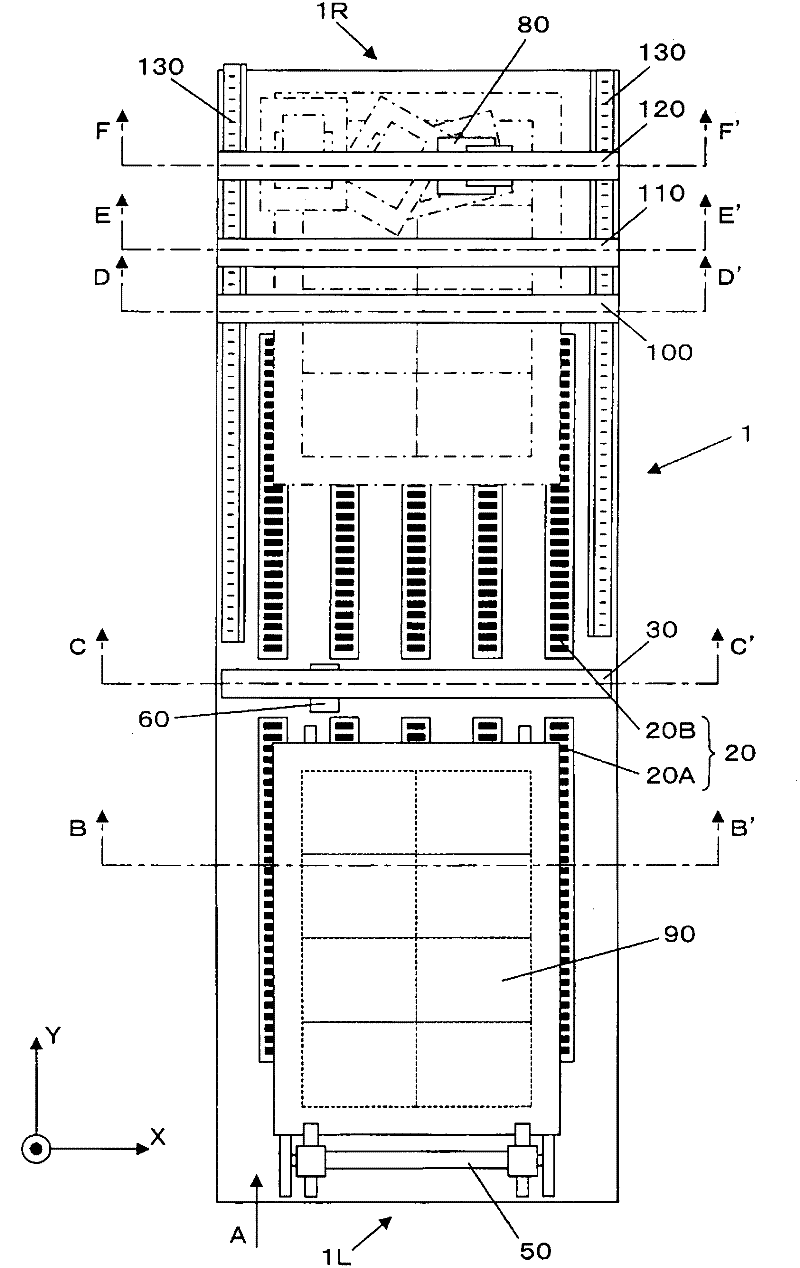

[0091] figure 1 It is a perspective view showing the overall structure of the substrate processing system 1 using the substrate processing method of the present invention. figure 2 Yes figure 1 Shown to the perspective view of A (except for the stand 10 described later). image 3 It is a top view of the substrate processing system 1 (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com