Lower cavity and cavity of food rubbish treatment machine

A food waste treatment and cavity technology, applied in the direction of solid waste removal, etc., can solve the problems of drive motor stuck, drain blockage, poor effect, etc., to achieve the effect of reducing resistance, facilitating removal, and eliminating hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

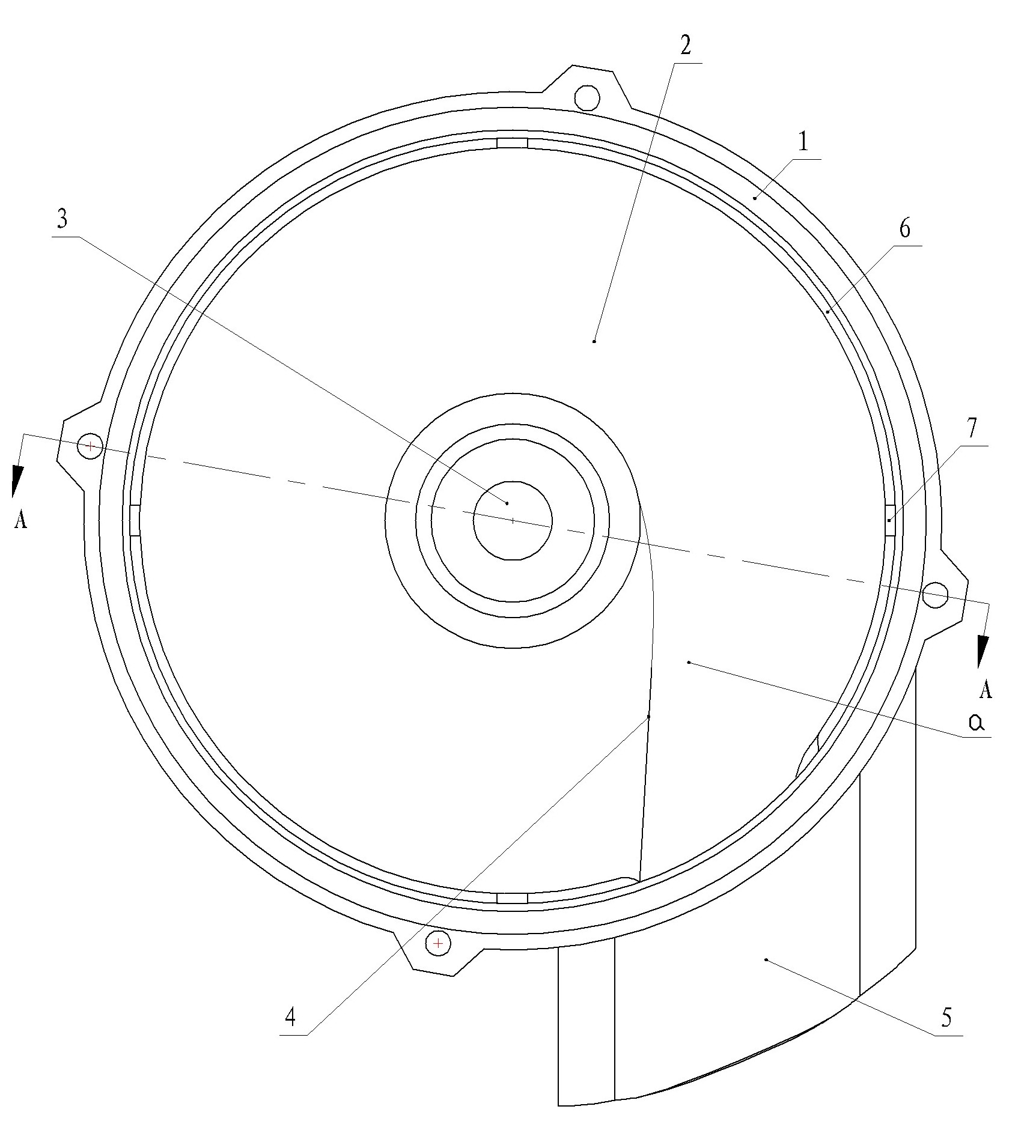

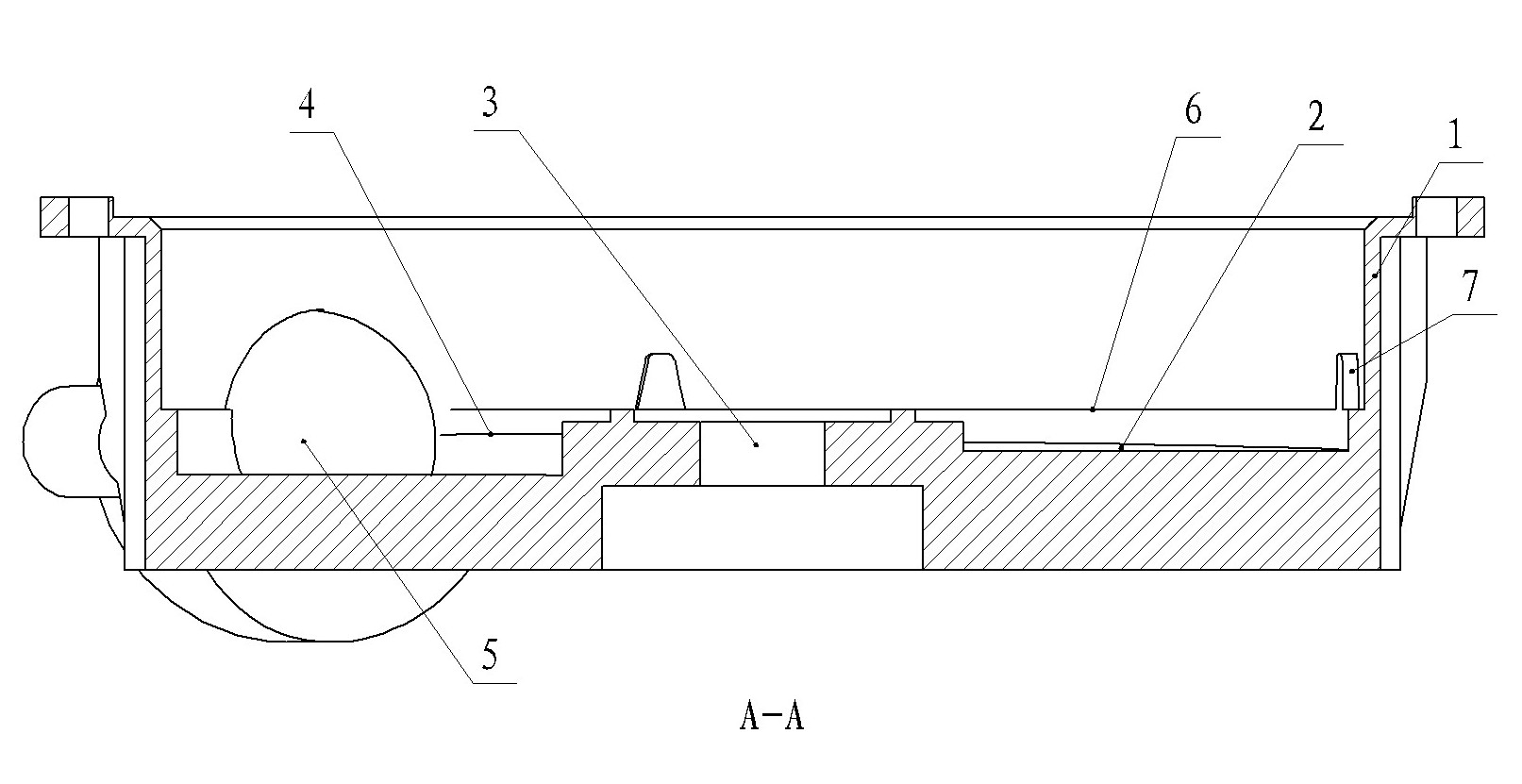

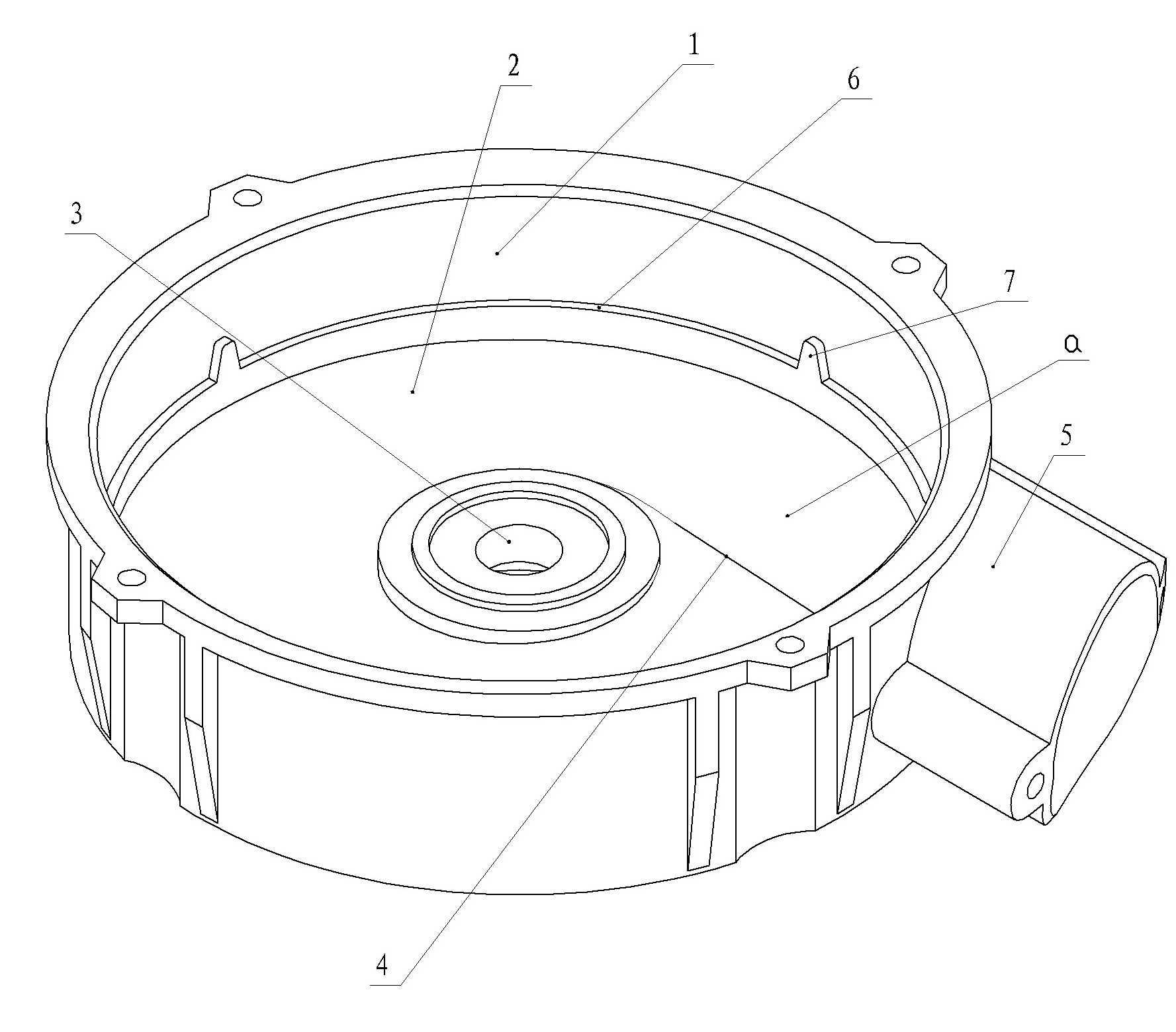

[0030] Embodiment one: see Figure 1-Figure 4 , the lower cavity of a food waste disposer in the figure, the lower cavity contains a cylindrical side wall and a lower circular bottom cover connected as one, the middle part of the bottom cover is provided with a shaft hole, and the side wall is provided with a discharge The inner surface of the discharge pipe is integrated with the bottom surface of the back cover through a transition connecting curved surface, and the axis of the discharge pipe is arranged in a direction approximately parallel to the tangential direction of the circumferential surface of the side wall.

[0031] The inner surface of the lower circular bottom cover is a helical surface, and the spiral descending direction matches the axial direction of the discharge pipe; The junction of the side walls.

[0032] The drop of the inner surface of the bottom cover near the discharge pipe is larger than the drop of the spiral surface.

[0033] A water-retaining co...

Embodiment 2

[0035] Embodiment two: see Figure 5 , Figure 6 ,as well as Figure 1-Figure 4 , a cavity of a food waste disposer in the figure includes an upper cavity and a lower cavity, and the upper and lower cavities are connected by fasteners and seals, and the lower cavity contains a cylindrical The side wall and the lower circular bottom cover, the middle part of the bottom cover is provided with a shaft hole, and the side wall is provided with a discharge pipe, the inner surface of the discharge pipe is connected with the bottom surface of the bottom cover through a transition connection surface, and the axis of the discharge pipe It is arranged in a direction approximately parallel to the tangential direction of the peripheral surface of the side wall.

[0036] The inner surface of the lower circular bottom cover is a helical surface, and the spiral descending direction matches the axial direction of the discharge pipe; The joint of the side wall; the drop of the inner surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com