Method for producing proportioned granulated feed by using crop straws on a large scale

A technology of crop straw and pellet feed, applied in animal feed, animal feed, application, etc., can solve problems such as burnt torches, and achieve the effects of removing obstacles, improving nutritional value, and quickly collecting and storing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

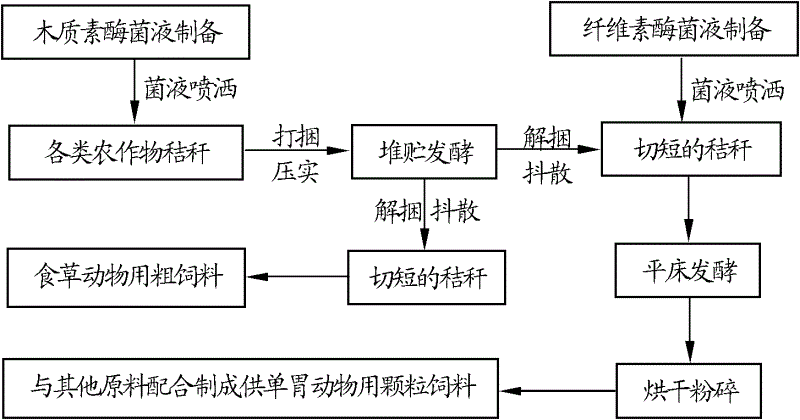

[0019] Below is in conjunction with process flow diagram of the present invention ( figure 1 ) illustrates an embodiment of the present invention.

[0020] 1. Preparation of ligninase bacterial liquid and cellulase bacterial liquid

[0021] (1) Preparation of ligninase bacterial liquid

[0022] 1. Culture medium and nutrient salt solution

[0023] Original medium: potato extract 1000mL, glucose 20g, KH 2 PO 4 3.0g, MgSO 4 ·7H 2 O 1.5g, vitamin B 1 1.0 g, 15.0 g of agar.

[0024] Secondary strain culture medium: 1.0g eugenol, 0.1g ammonium tartrate, 2.6g peptone, KH 2 PO 4 1.0g, Na 2 HPO 4 0.2g, MgSO 4 ·7H 2 O 0.5g, agar 18.0g, add distilled water to 1000mL.

[0025] Tertiary strain culture medium: glucose 10g, ammonium tartrate 0.1g, MgSO 4 ·7H 2 O 0.5g, KH 2 PO 4 0.2g, MnSO 4 ·H 2 O 0.035g, CuSO 4 ·5H 2 O 0.007g, add distilled water to 1000mL.

[0026] The composition and formula (content per liter of water) of the nutrient salt solution for ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com