Silk protein nanofiber gel dressing with pressure spreadability, its preparation method and application

A technology of nanofibers and silk proteins, which is applied in pharmaceutical formulations, bandages, drug delivery, etc., to achieve the effects of simple preparation method, promoting vascularization ability, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

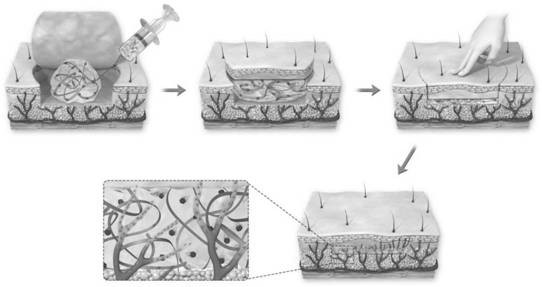

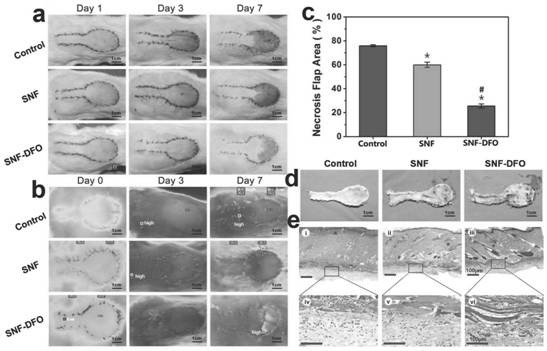

[0034] The present invention provides a method for preparing a silk protein nanofiber gel dressing with pressure spreadability, comprising the following steps: S1) mixing and stirring the first silk protein nanofiber gel with water to obtain a silk protein with changed rheology Nanofiber gel; mixing the drug for promoting angiogenesis with the second silk protein nanofiber gel to obtain drug-loaded silk protein nanofiber gel; S2) mixing the rheologically modified silk protein nanofiber gel with drug loading The silk protein nanofiber gel is mixed and stirred to obtain a silk protein nanofiber gel dressing with pressure spreadability.

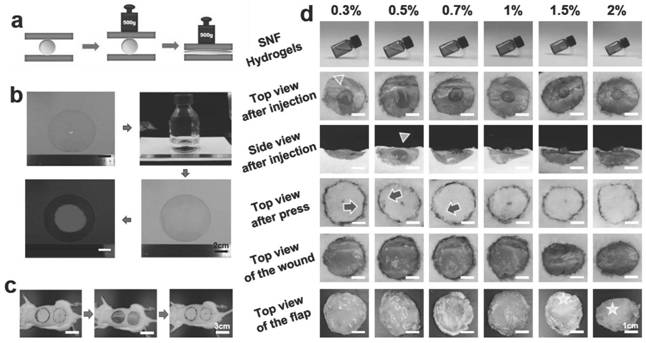

[0035]The present invention firstly regulates the rheology of the silk protein nanofiber gel to a suitable range by adjusting the concentration of the silk protein nanofibers, and then further regulates the rheology through suitable shearing action, and finally obtains ideal rheological properties and realizes coagulation. Mild pressure of the g...

Embodiment 1

[0050](1) Add deionized water to the silk protein nanofiber gel with a concentration of 2.5wt% (the crystallinity of silk protein nanofibers is 40%, the diameter is 20 nm, and the length is 1 μm), and the concentration is adjusted to 0.8wt%, using The magnetic stirrer was stirred at 800 rpm for 24 hours;

[0051] (2) Mix the deferoxamine powder with the silk protein nanofiber gel with a concentration of 1.2 wt% (the crystallinity of the silk protein nanofibers is 40%, the diameter is 20 nm, and the length is 1 μm), so that the concentration of deferoxamine is 1 mg / ml, stirred at 200 rpm for 4 hours, then centrifuged at 12,000 rpm for 30 minutes, and the bottom was a drug-loaded silk protein nanofiber gel;

[0052] (3) Mix the above-mentioned drug-loaded nanofiber gel and the gel with the stirring treatment in (1) according to the volume ratio of 1:15, and then stir for 6 hours at a rotating speed of 1000 rpm, so that the two gels are fully mixed, and mixed The rheology of th...

Embodiment 2

[0059] (1) Add deionized water to the silk protein nanofiber gel with a concentration of 2 wt% (the crystallinity of silk protein nanofibers is 40%, the diameter is 20 nm, and the length is 1 μm), the concentration is adjusted to 1 wt%, and magnetic stirring is used. The machine was stirred at a speed of 900 rpm for 24 hours;

[0060] (2) Mix the deferoxamine powder with the silk protein nanofiber gel with a concentration of 1 wt% (the crystallinity of the silk protein nanofibers is 40%, the diameter is 20 nm, and the length is 1 μm), so that the deferoxamine concentration is 2 mg / ml, stirred at 200 rpm for 6 hours, then centrifuged at 14,000 rpm for 25 minutes, and the bottom was a drug-loaded silk protein nanofiber gel;

[0061] (3) Mix the above-mentioned drug-loaded nanofiber gel and the gel with stirring in (1) according to the volume ratio of 1:24, and then stir for 14 hours at a rotating speed of 600 rpm, so that the two gels are fully mixed, and mixed The rheology of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com