Gold-core silver-shell nanometer composite material and preparation method thereof

A nanocomposite material and composite material technology, which is applied in the field of gold core silver shell nanocomposite material and its preparation, can solve the problems of high biological toxicity of silver nanoparticles, difficult chemical properties, high price of gold nanomaterials, etc. Time, synthesis method, environmental protection and energy saving, and the effect of increasing the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In the present invention, all the chemical reagents used are analytically pure or above, without any treatment. Chlorauric acid (HAuCl 4 4H 2 O) and ascorbic acid (L-ascorbic Acid) were purchased from Shanghai Titan Technology Co., Ltd. Cetyl ammonium bromide (CTAB) and cetyl ammonium chloride (CTAC) were purchased from Aladdin Co., Ltd. Hydrochloric acid (HCl, 37%), sodium borohydride (NaBH 4 ), silver nitrate (AgNO 3 ) and trisodium citrate (Na 3 Ct) was purchased from Sinopharm Co., Ltd. The deionized water used in the experiment was prepared in real time by the Millipore-Q ultrapure water system (Millipore, USA), and the conductivity was not lower than 18.2MΩcm -1 .

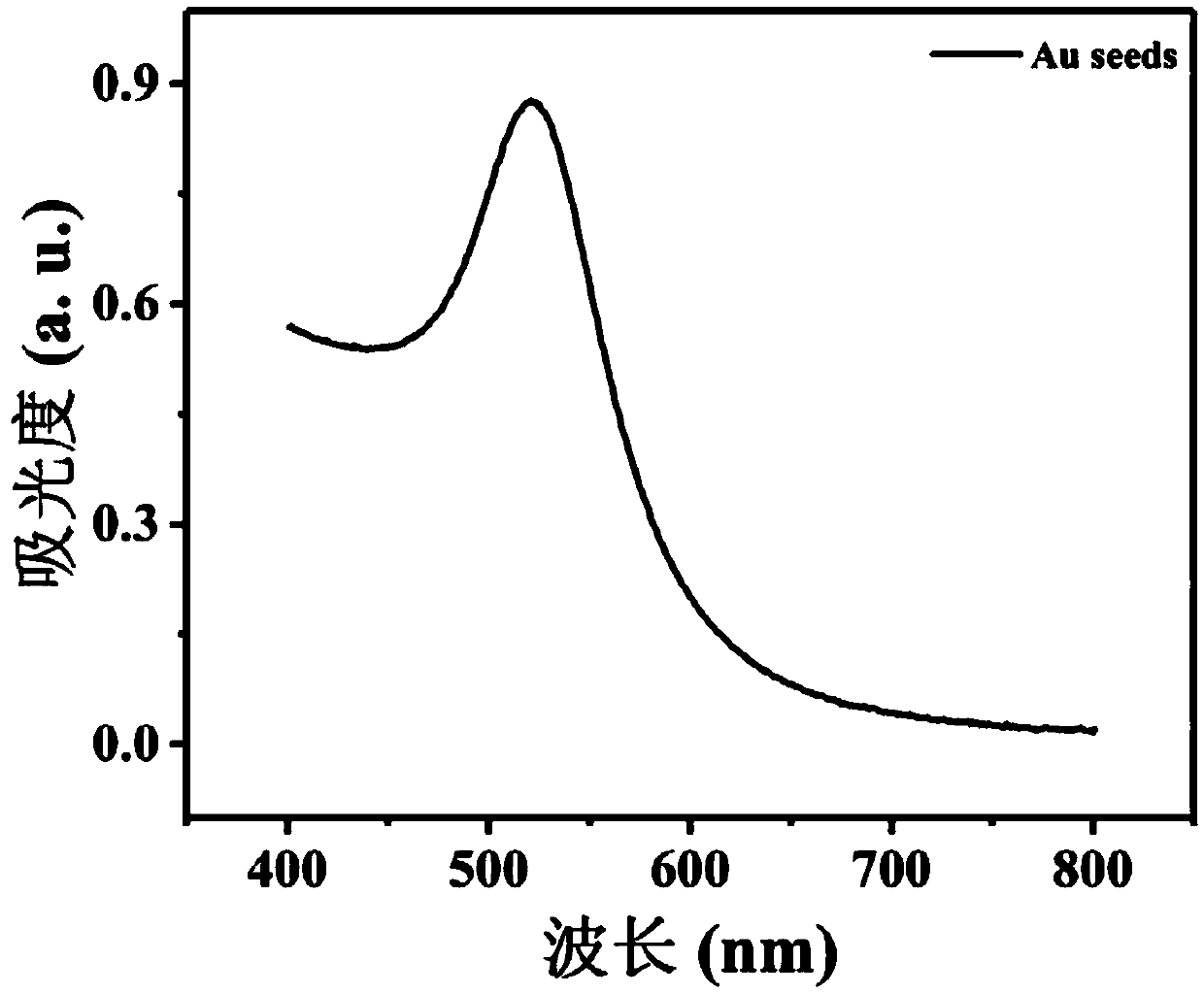

[0033] (1) Preparation of Au nano-seeds

[0034] First, 0.5 ml of 5 millimole per liter Chlorauric acid solution, 5 ml of 0.1 mol cetyl ammonium chloride per liter and 0.5 ml of 0.1 mol trisodium citrate were mixed and stirred evenly. Thereafter, 0.25 mL of a freshly prepared ice-cold 25 mmol...

Embodiment 2

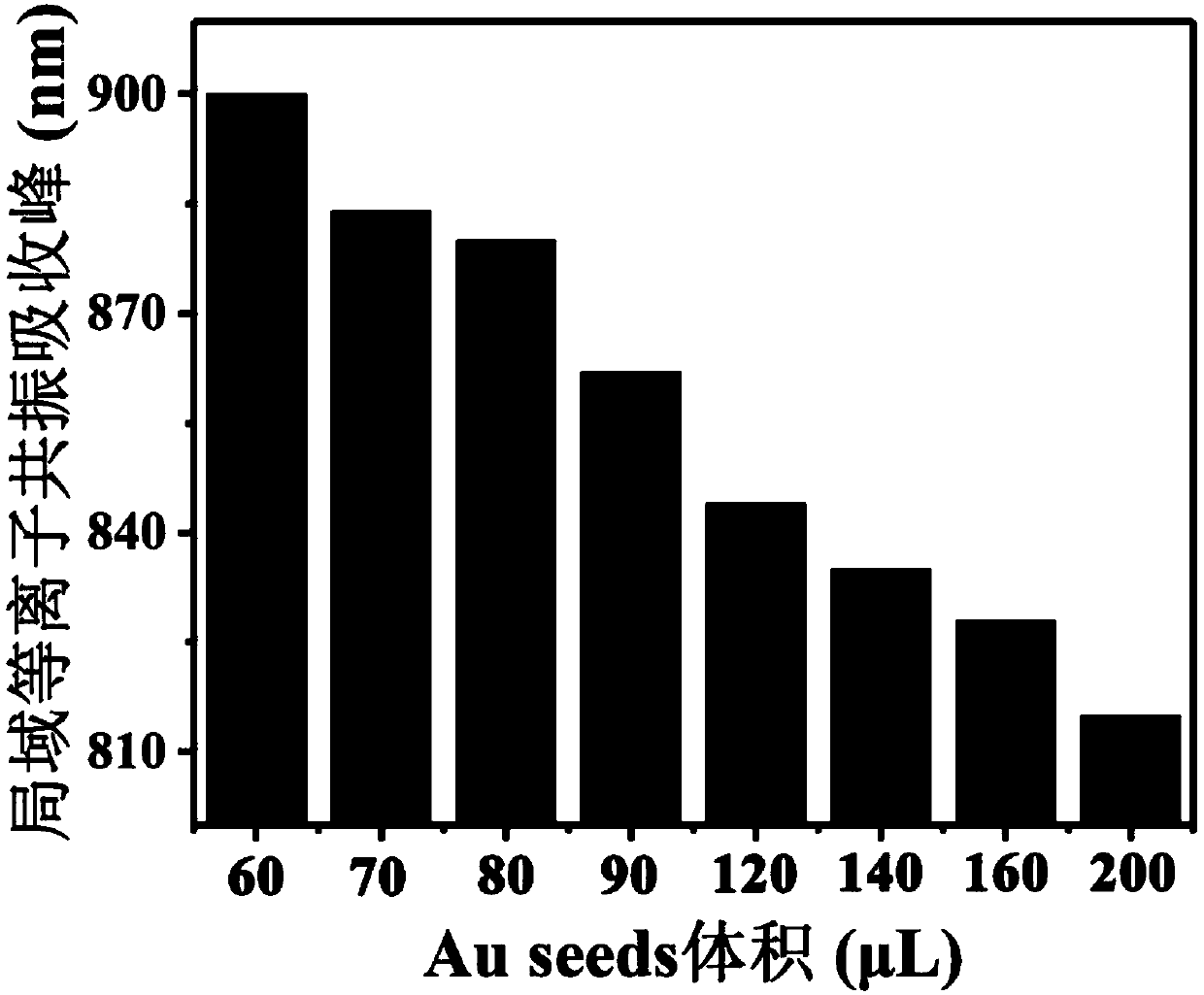

[0042] Adopt the preparation method similar to embodiment 1, difference is:

[0043] (1) 20 milliliters of CTAC containing 2 micromoles (μmol) chloroauric acid and 40 micromoles of trisodium citrate and 1000 micromoles of CTAC were mixed, and 5 micromoles of sodium borohydride were added while stirring at 25° C. and 400 rpm, Continue to stir to make it evenly mixed, then place it in an oil bath at 70°C for reaction, centrifuge after 4 hours, and cool to room temperature to obtain 2 micromoles of Au seeds;

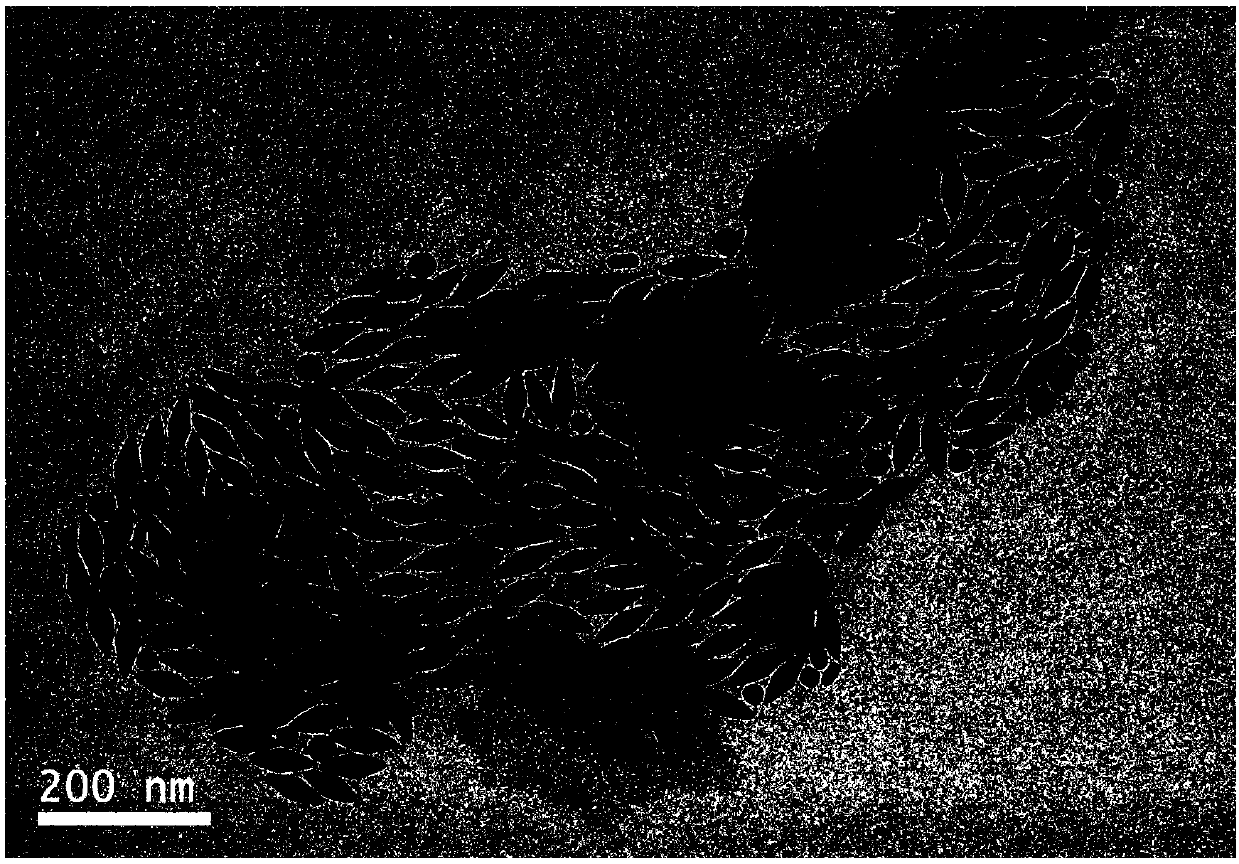

[0044] (2) A solution of 5 micromoles of chloroauric acid, 1 micromoles of silver nitrate and 200 micromoles of hydrochloric acid was sequentially added to 10 milliliters of 0.1 moles per liter of hexadecyl trimethyl bromide at 25°C and 400 rpm. Ammonium solution, then add 8 micromoles of ascorbic acid, then add 0.02 micromoles of Au seeds prepared in step (1), transfer to a 25°C water bath for reaction, centrifuge after 2.5h, and ultrasonically disperse the precipitate int...

Embodiment 3

[0048] Adopt the preparation method similar to embodiment 1, difference is:

[0049] (1) 20 milliliters containing 5 micromoles of chloroauric acid, 80 micromoles of trisodium citrate and 1000 micromoles of cetyltrimethylammonium chloride solution were stirred while adding 12.5 micromoles at 35°C and 1200rpm. Micromole of sodium borohydride, continue to stir to make it evenly mixed, then place it in an 85°C oil bath for reaction, centrifuge after 1h, and cool to room temperature to obtain 5 micromole of Au seeds;

[0050] (2) A mixed solution containing 30 micromoles of chloroauric acid, 6 micromoles of silver nitrate and 120 micromoles of hydrochloric acid was added to 10 milliliters of hexadecyl at a concentration of 0.1 mole per liter at 35°C and 1200 rpm. Trimethylammonium bromide solution, then add 48 micromoles of ascorbic acid, then add 0.45 micromoles of Au seeds prepared in step (1), transfer to a 35°C water bath for reaction, centrifuge after 1h, and disperse the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com