Five-axle numeric control milling machine

A technology of numerical control milling machine and numerical control device, which is applied in the direction of milling machine, milling machine equipment, milling machine equipment details, etc., can solve the problems that cannot meet the production demand, the scope of application is small, and cannot process inclined holes, etc., and achieve reasonable structure, convenient operation, and adjustable angle control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

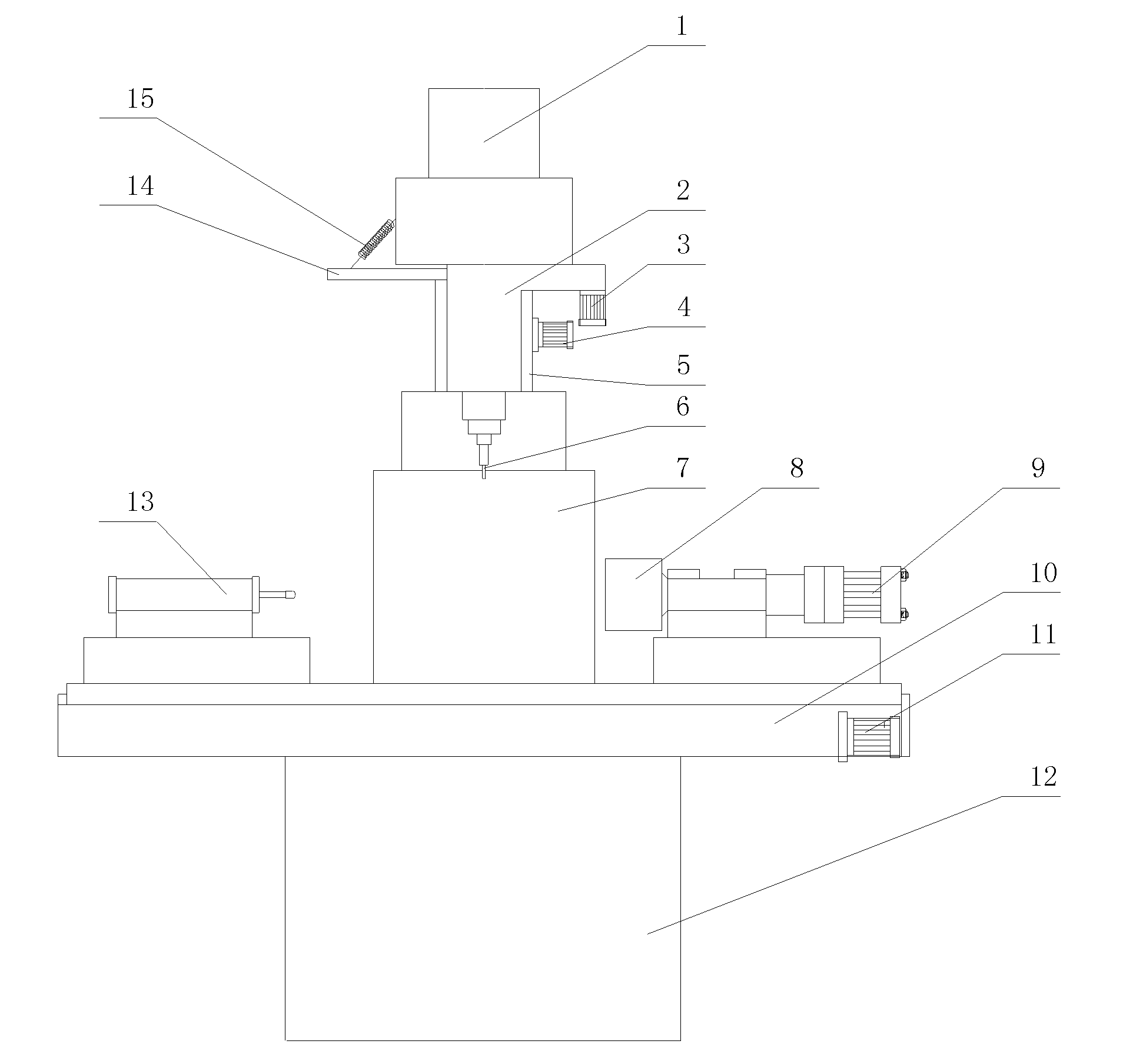

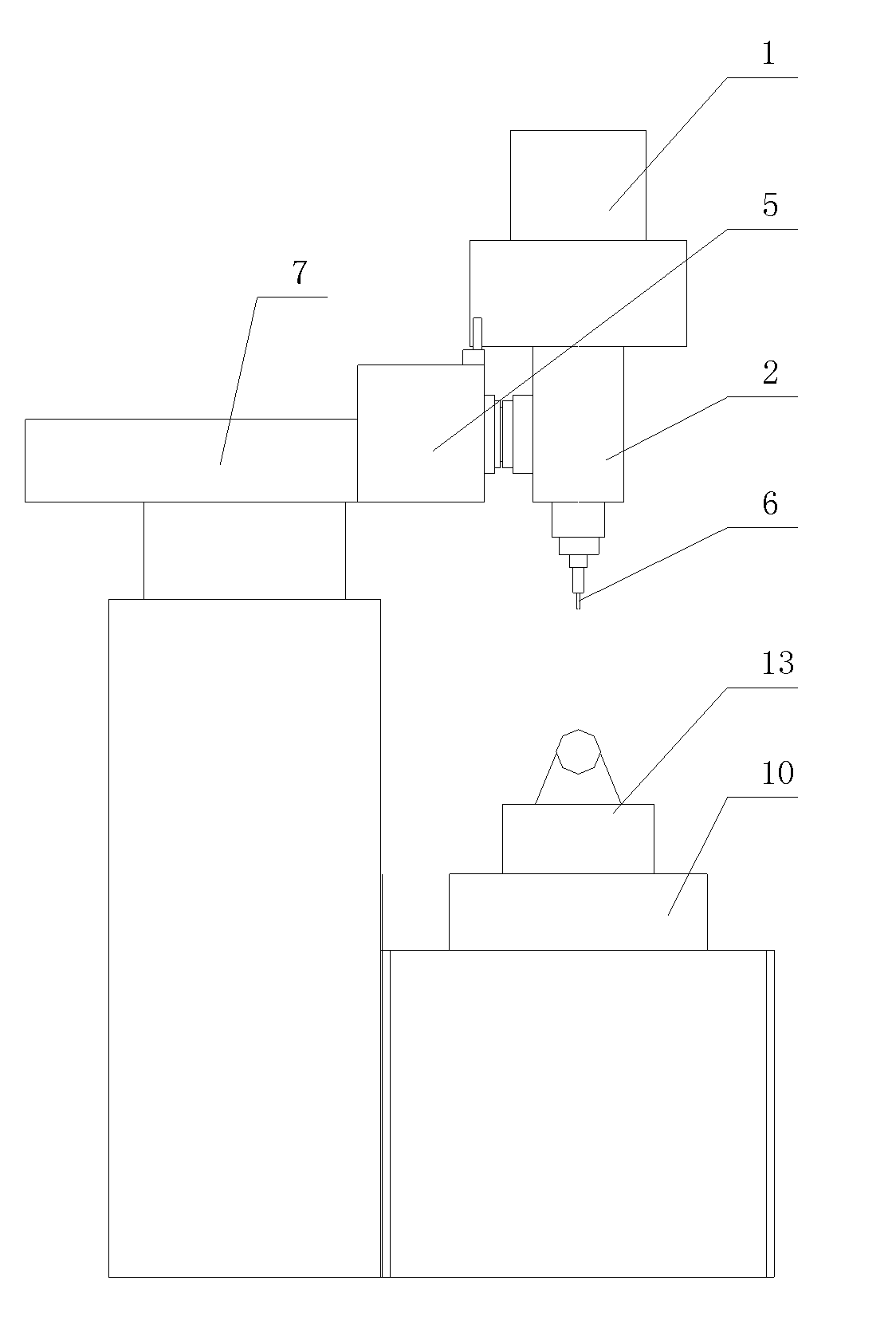

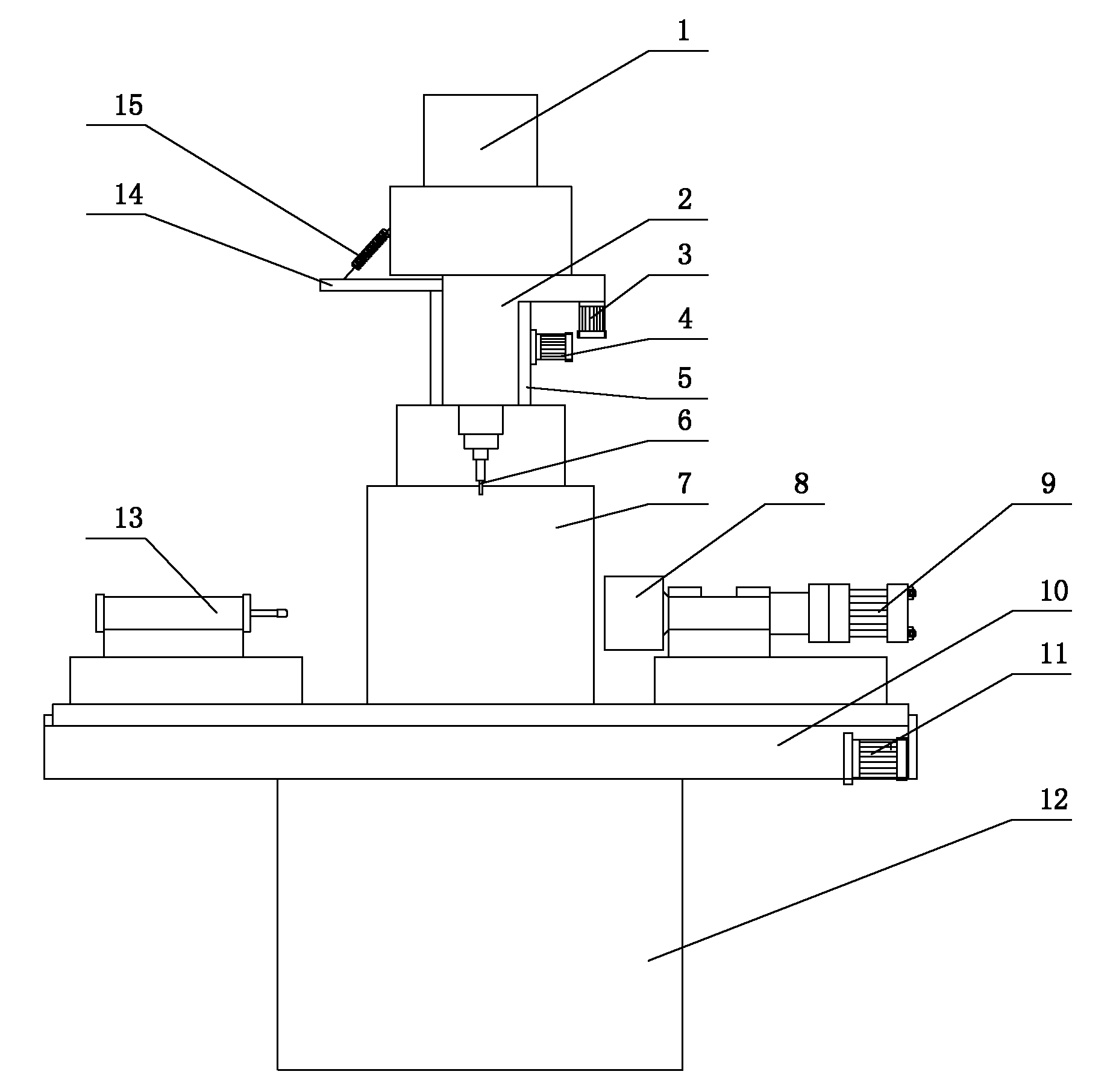

[0014] A five-axis CNC milling machine, comprising a bed 12, a workbench 10, a chuck 8, a tailstock 13, a tool holder 2 for installing a tool 6, a tool holder mounting frame 7 and a numerical control device (not shown in the figure), the workbench Installed on the guide rail of the bed and driven by its servo motor (not shown in the figure) to move along the Y direction, the chuck and tailstock are installed on the guide rail on the worktable through their respective mounting seats, and driven by the servo motor 11 Together they move along the X direction, the chuck is driven to rotate by its servo motor 9, the tool seat is installed above the worktable through the tool seat mounting frame, and the tool is driven by its servo motor 3 to lift ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com