Method for manufacturing super-long and high-precision shaft gear

A manufacturing method and technology of shaft gears, applied in the direction of gear tooth manufacturing devices, manufacturing tools, components with teeth, etc., can solve problems such as the inability to realize the processing and manufacturing of super-long, high-precision shaft gear multipliers, and reducer transmissions , to achieve the effect of shortening installation and calibration time, improving work efficiency and reducing installation eccentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

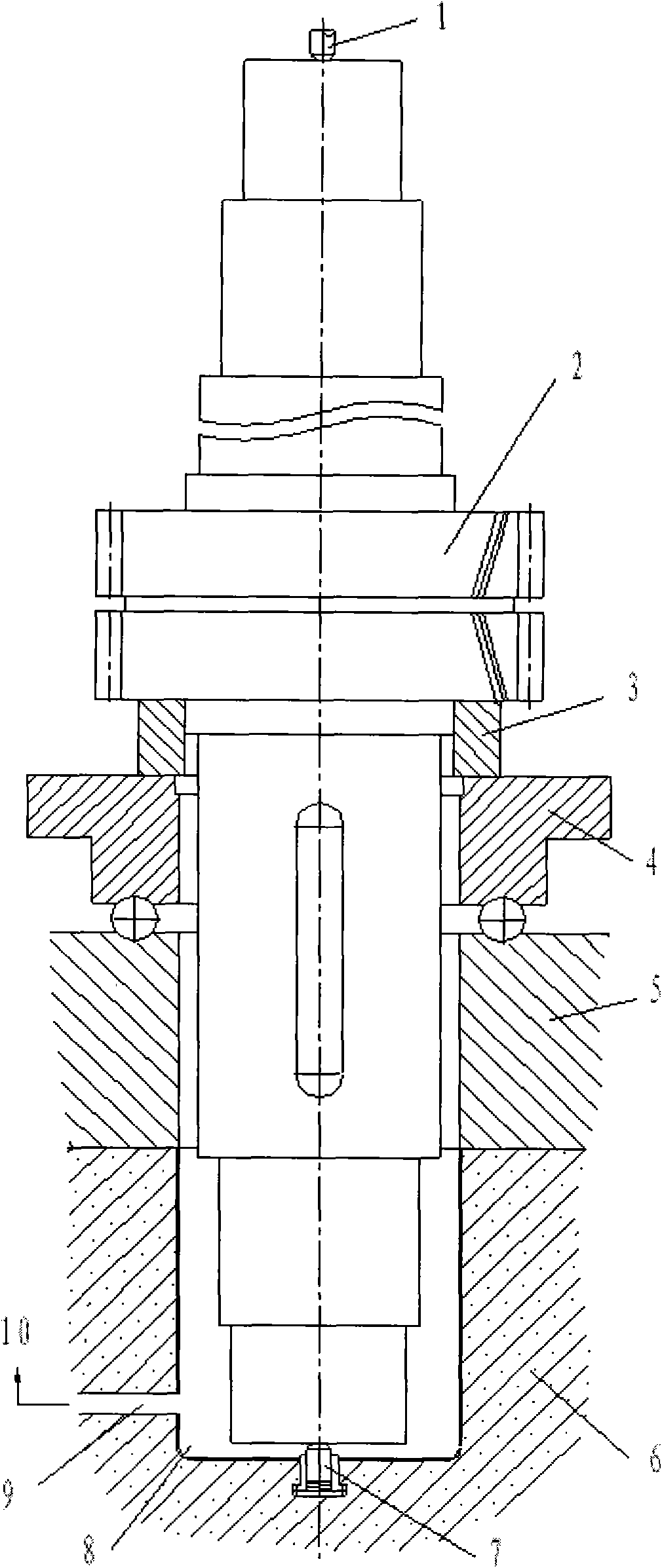

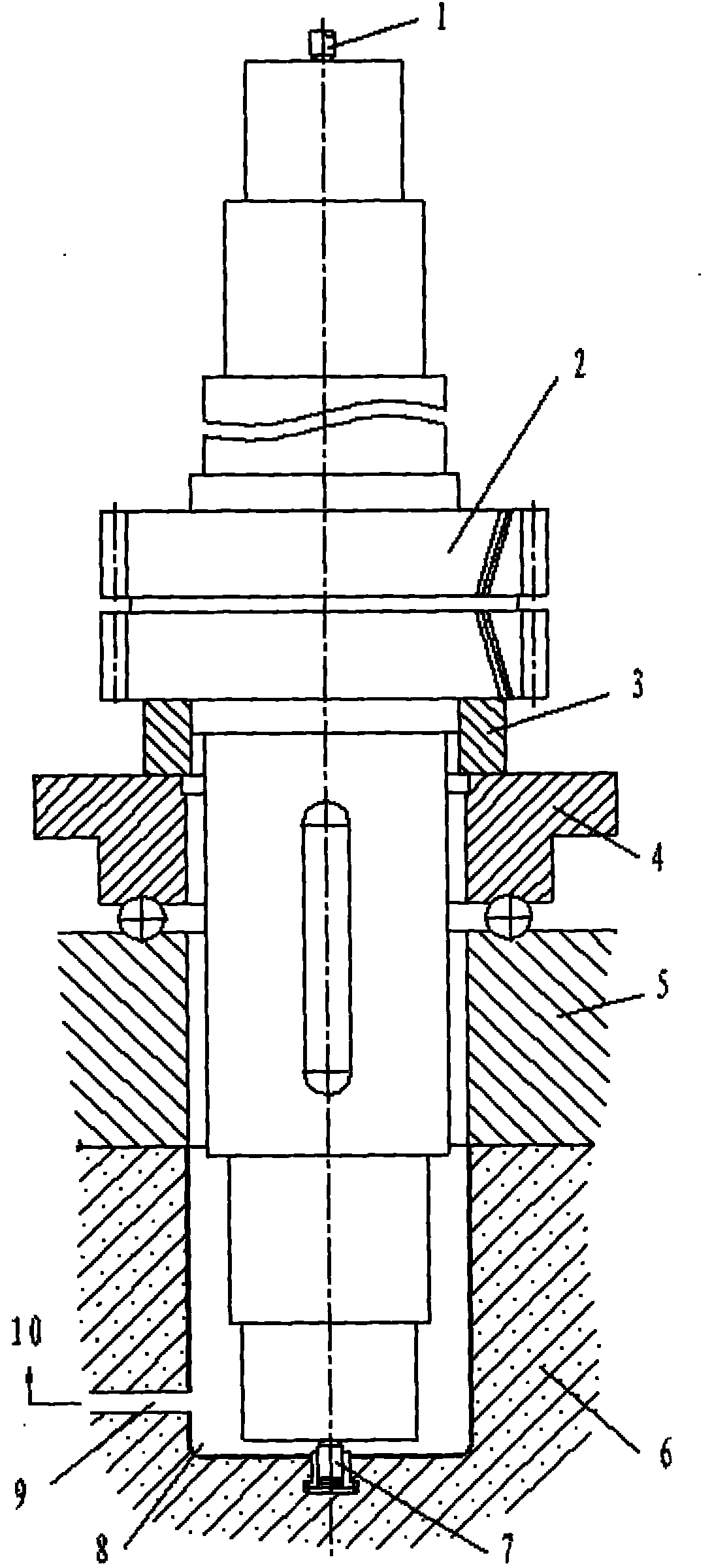

Embodiment 1

[0015] A method for manufacturing super-long, high-precision shaft gears. This method uses self-designed technical indicators. The maximum machining diameter is 2000mm, the maximum shaft length is 2800mm, and the diameter of the worktable is 1850mm; a φ900mm through hole is reserved in the center of the workbench. There is a sealing cover on the table and a RAPID 2000 CNC gear grinding machine produced by the German HOFLER company, mainly through the preparation and installation of the tooling, the adjustment of the workpiece clamping, and the manufacture of the transmission device of the increaser and reducer according to the processing route; After the improvement of tooling preparation and installation, and workpiece clamping and adjustment steps, the maximum diameter of gears can be processed up to 2000mm, the shaft length is 4800mm, and the shaft diameter is less than 900mm. Ultra-long, high-precision shaft gears, the precision can reach DIN3962 standard 2-5. In the manufa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com