Oil cylinder driving mechanism with buffer function for clamp

A technology of driving mechanism and oil cylinder, which is applied in the direction of clamping, manufacturing tools, metal processing machinery parts, etc., can solve the problems of poor stability and large impact of oil cylinder driving mechanism, achieve good stability and overcome the effect of end impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

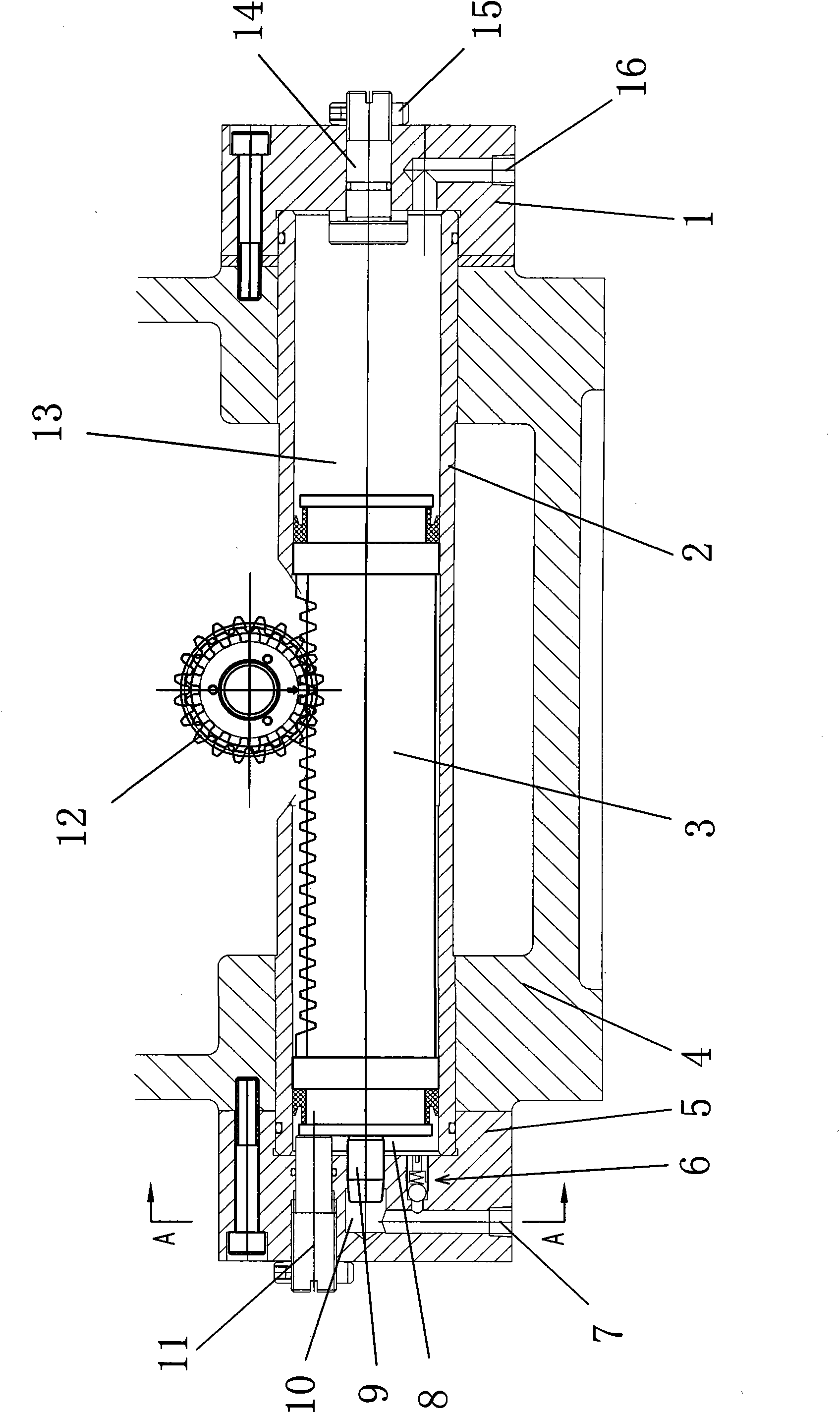

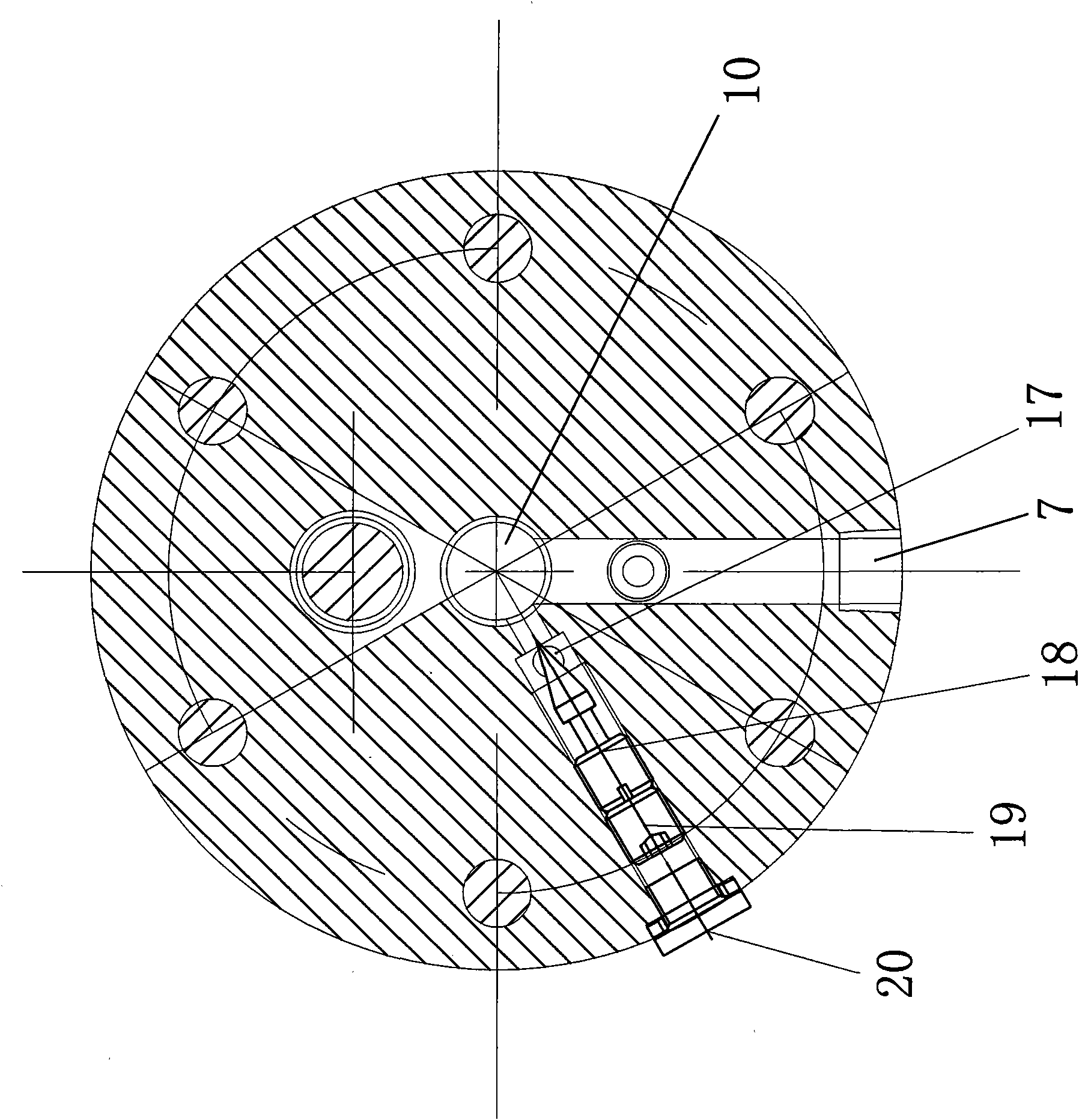

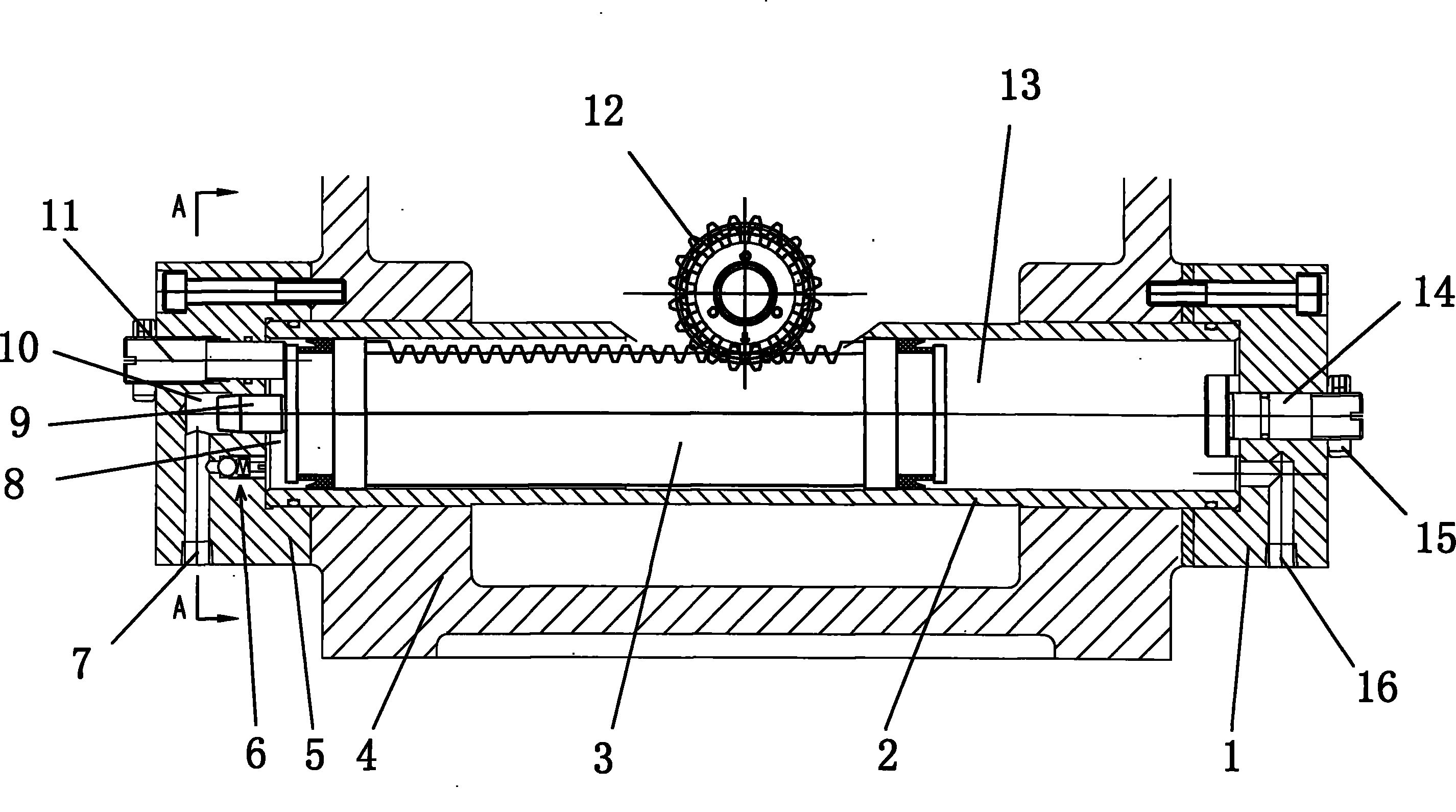

[0011] Such as figure 1 , 2 Shown: 4 is the clamp body, on which the clamp body 4 is fixed with an oil cylinder 2, the right end of the oil cylinder 2 has a right end cover 1, the right end cover 1 is fixedly connected with the clamp body 4 by bolts, and the center of the right end cover 1 is threaded. The right adjusting bolt 14 is fastened and positioned with a fastening nut 15 for setting the position of the right dead center of the piston. A right oil port 16 is processed on the right end cover 1 for connecting with the hydraulic control mechanism. The right end of the rack piston 3 matched with the oil cylinder 2 forms a right cavity 13 . The right cavity 13 communicates with the right oil port 16 .

[0012] The middle part of the rack piston 3 is exposed from the opening above the oil cylinder 2 and meshed with the gear 12. The rotating shaft of the gear 12 is connected with the fixture turntable to drive the turntable to rotate.

[0013] There is a left end cover 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com