Hydraulic type high-pressure water electrostatic spraying nozzle

A high-pressure water and hydraulic technology, which is applied in the direction of electrostatic spraying device, spraying device, spraying discharge device, etc., can solve the problem of low utilization rate of atomized spraying, achieve the improvement of droplet penetration ability, convenient use, and slow down the loss of pesticides Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

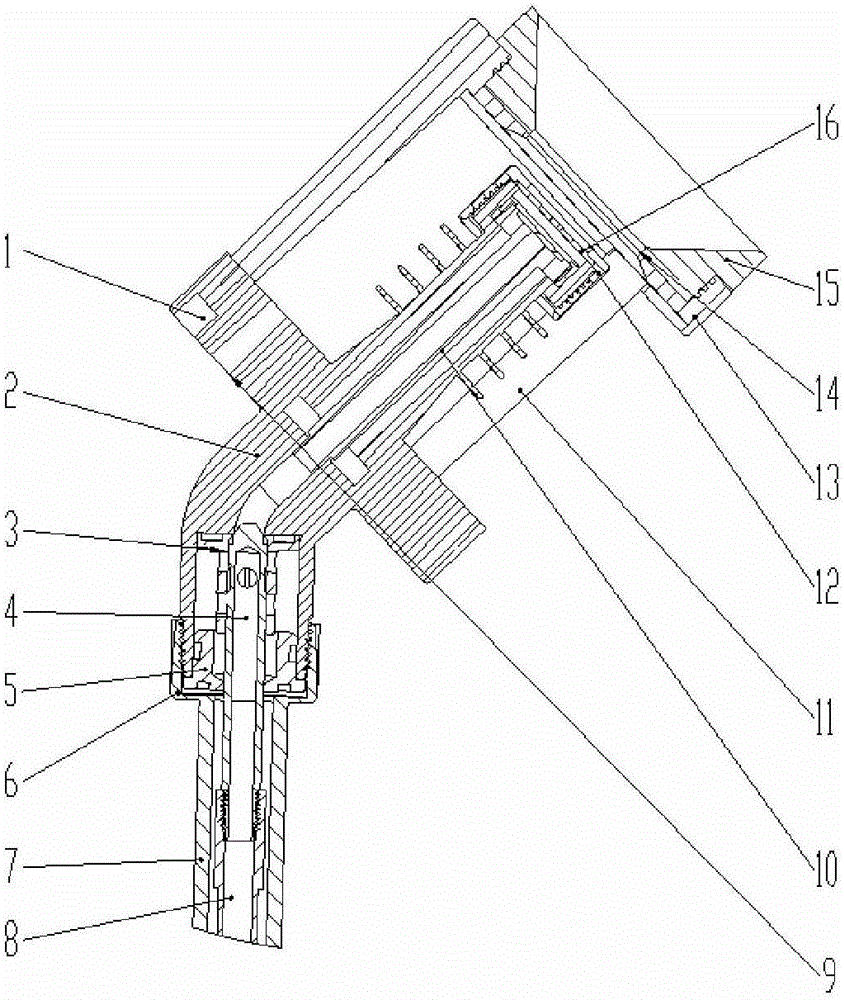

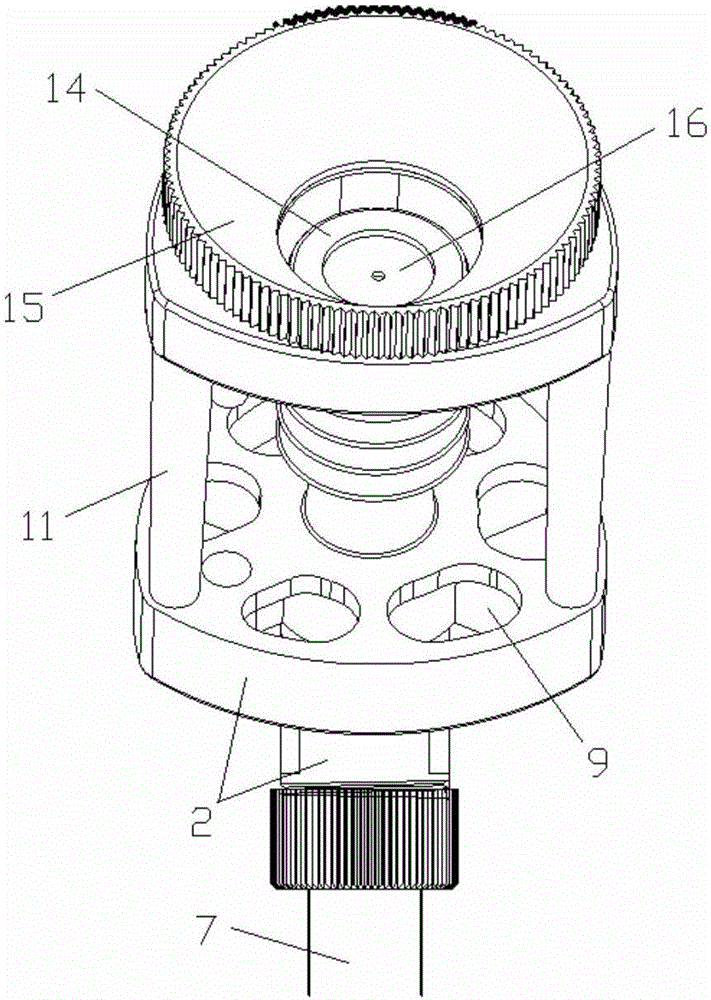

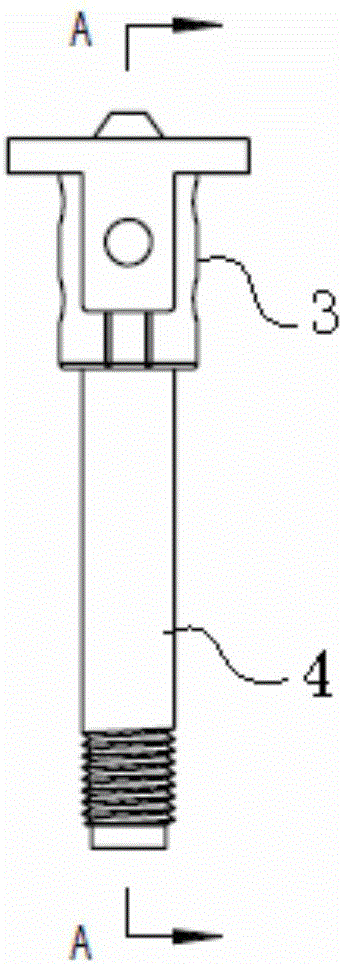

[0041] see figure 1 and figure 2 , the hydraulic high-pressure water electrostatic nozzle shown in the figure includes a hydraulic nozzle seat 2, a water swirl core 3, a water diversion core 4, a sealing end cover 5, a spray rod jacket 7, a spray rod 8, and a water guide swivel core 10 , Electrostatic spray head foot 11, nozzle cap 12, induction electrode seat 13, ring induction electrode 14, induction electrode ring end cover 15 and nozzle sheet 16, etc., are mainly divided into spray parts and charging parts.

[0042] Wherein, the spray part comprises the nozzle plate 16 that is arranged on the water outlet end of the hydraulic nozzle seat 2, the nozzle plate 16 is fixed on the water outlet end of the hydraulic nozzle seat 12 by the nozzle cap 12, and the nozzle plate 16 is provided with small holes for spraying, The water inlet end of the hydraulic nozzle seat 2 communicates with the spray rod 8 connected to the water source through the rotating water core. A water-guidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com