Inserting installation type one-way speed regulating valve

A one-way speed regulating valve, a cartridge technology, applied in the direction of control valve, safety valve, balance valve, etc., can solve the problems of difficult manufacturing, complex structure, large volume of the speed regulating valve, etc., and achieve simple structure and small volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

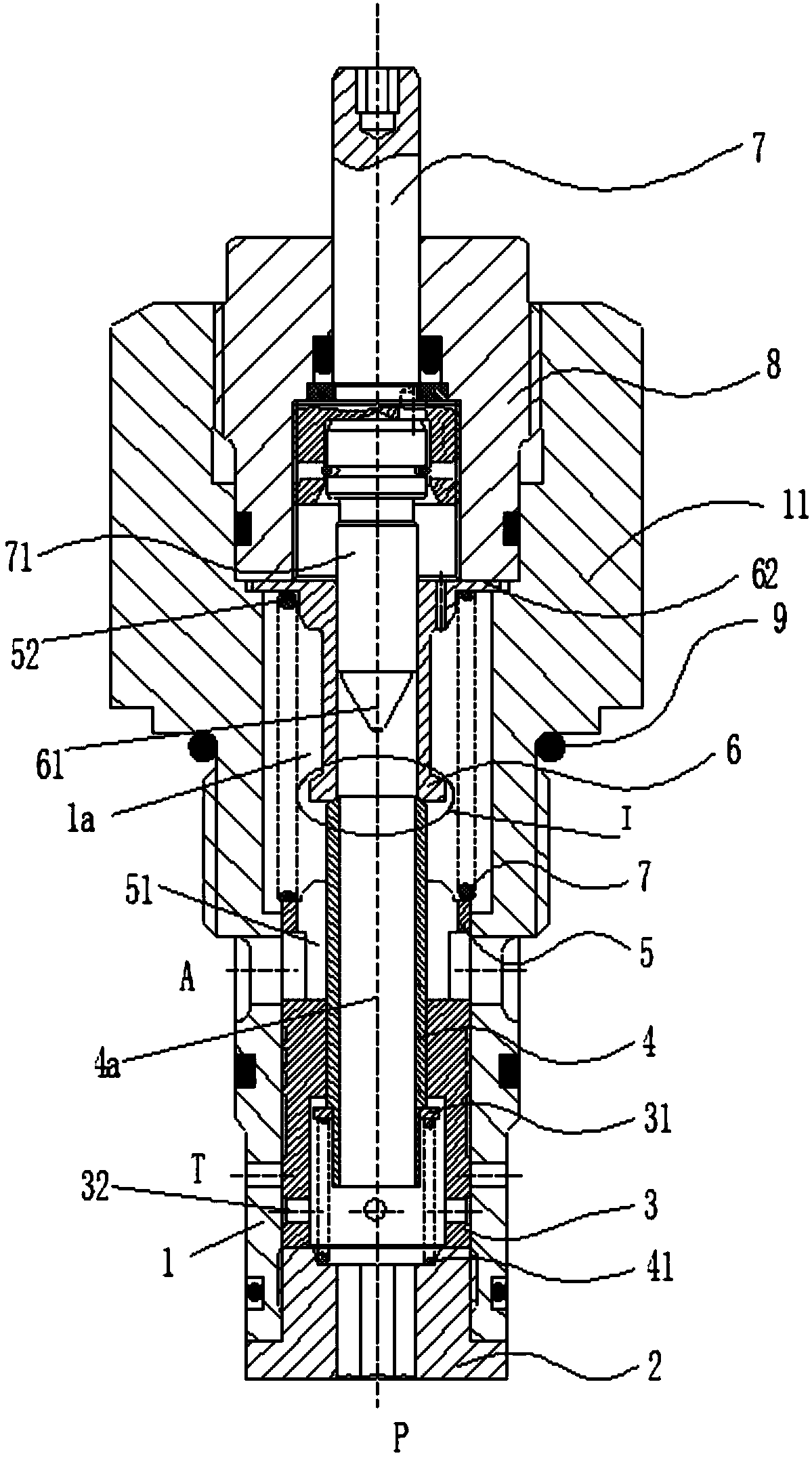

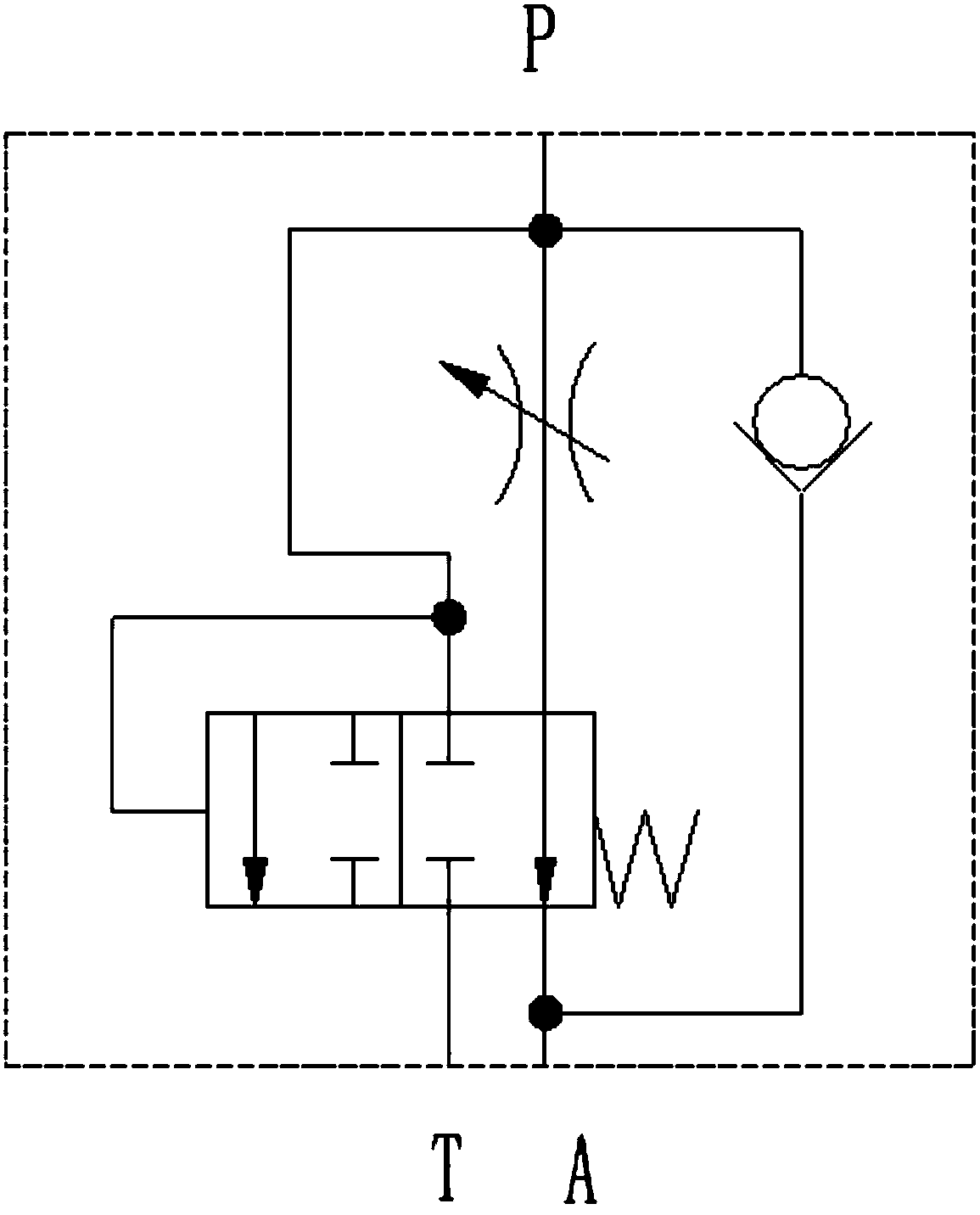

[0021] Such as Figure 1 to Figure 2 Shown is the structural representation of the present invention,

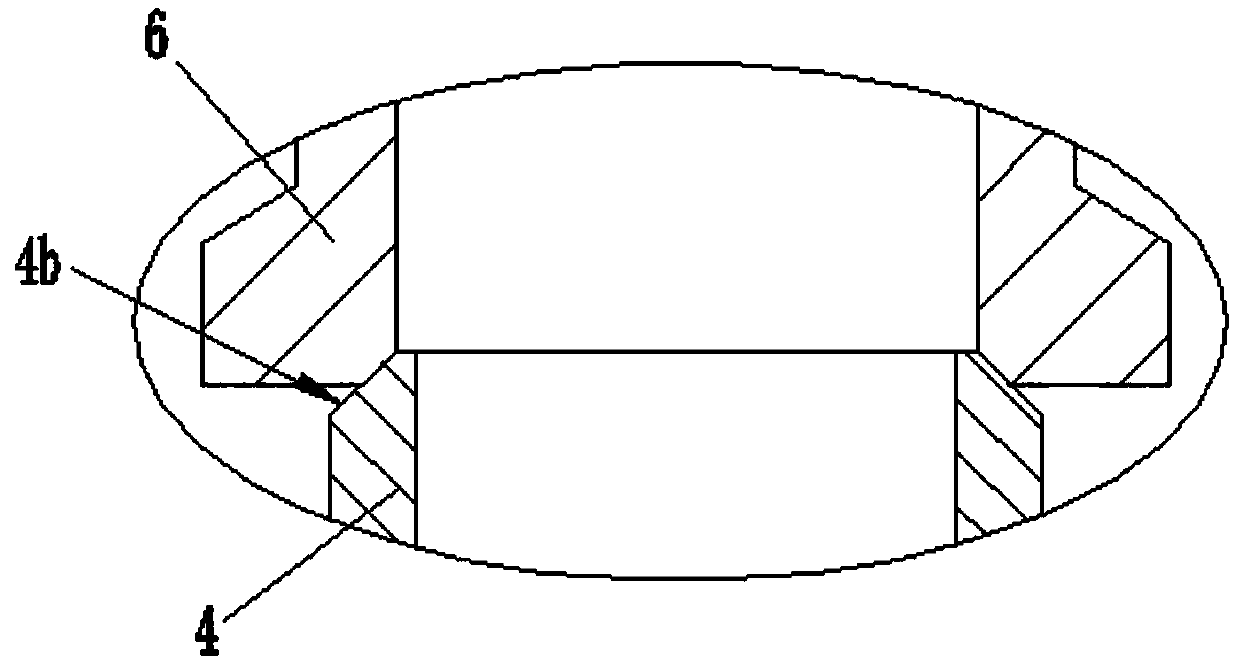

[0022] The reference signs are: P port, A port, T port, valve body 1, flow chamber 1a, external thread 11, screw plug 2, pressure compensating valve core 3, gasket 31, through hole 32 one-way valve core 4. Flow hole 4a, slope 4b, first spring 41, bushing 5, flow groove 51, second spring 52, throttle valve sleeve 6, throttle groove 61, limit edge 62, adjustment rod 7, adjustment Cover 8, sealing ring 9.

[0023] Such as Figure 1 to Figure 2 as shown,

[0024] A plug-in one-way speed regulating valve, including a valve body 1, the lower end of the valve body 1 is provided with a screw plug 2, the center of the screw plug 2 is provided with a P port, and the side wall of the valve body 1 is provided with an A port and T port, T port is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com