Throttling device for high pressure water-feeding pump of industrial boiler

A throttling device and industrial boiler technology, which is applied in the direction of water supply control, preheating, steam generation, etc., can solve the problems of pump impeller impact, large water supply pressure changes, and unstable steam and electricity loads, so as to ensure stability and improve Efforts to improve the effect of safe and economical operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

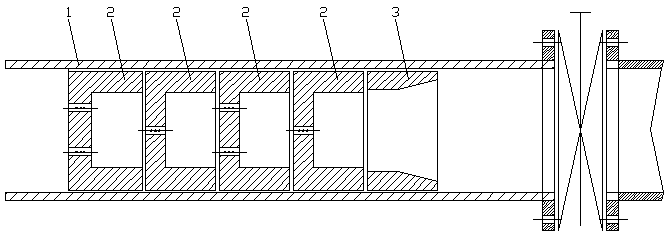

[0008] like figure 1 As shown, the throttling device of the industrial boiler high-pressure feed water pump of the present invention includes a throttling straight pipe 1, and the end face of the throttling straight pipe 1 is equipped with a throttling nozzle 3, and several nozzles are installed in an internal staggered arrangement at an angle of 45° or 90°. Throttle orifice 2.

[0009] During production, the throttling nozzle 3 is first welded to the end face of the throttling straight pipe 1, and then the throttling orifice plates are staggered in turn and installed inside the throttling straight pipe 1 at an angle of 45° or 90°, and the finished throttle The device is welded in front of the primary recirculation door of the outlet pipe of the boiler feed water pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com