Finish machining method for large parts difficult to cut

A technology for machining and difficult-to-cut parts, applied in the field of finishing of large and difficult-to-cut parts, can solve the problem of high processing cost, improve production efficiency, ensure product quality, and reduce machining errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, the present invention provides a tool wear self-adaptive compensation method in the machining process, which effectively reduces part errors caused by tool wear and improves part machining accuracy and production efficiency by adopting self-adaptive tool wear compensation.

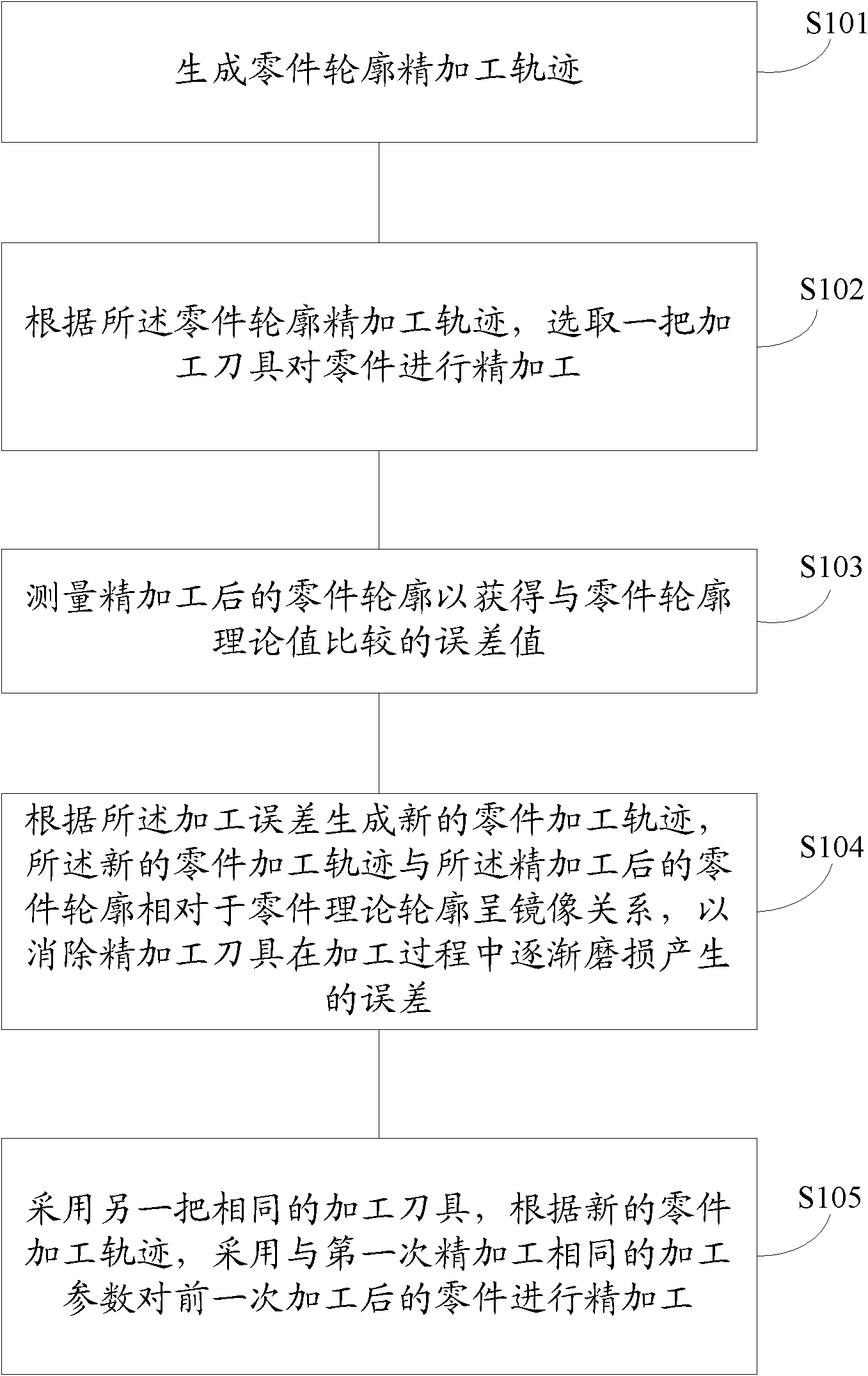

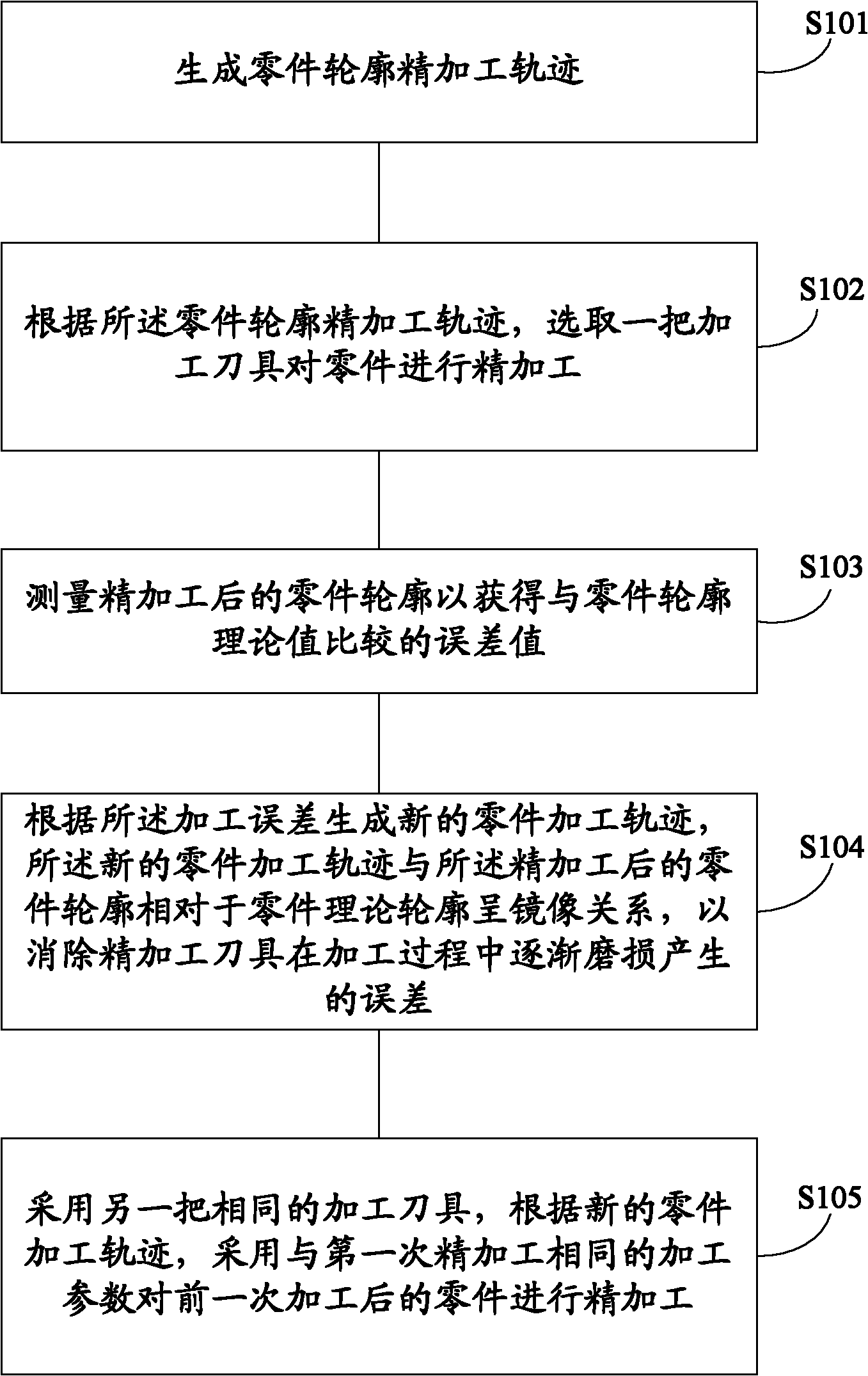

[0016] The technical solutions of the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. Such as figure 1 As shown, the self-adaptive compensation method for tool wear in the machining process of this embodiment includes the following steps:

[0017] Step S101: Generating a contour finishing track of the part. Concretely, described part profile finishing track can be compiled by hand, also can be by PRO-E (Parametric Technology Corporation-Engineer) or other CAD (Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com