Digital textile printing high-speed output equipment

An output device and high-speed technology, applied to typewriters, printing, etc., can solve the problems of reducing production efficiency, difficulty in accurately determining the initial position of dyes, low efficiency, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In the following description, the same components in the drawings are labeled with the same symbols as much as possible, and at the same time, to avoid obscuring the central idea of the present invention, detailed descriptions of related basic structures and functions are omitted.

[0048] The dyed objects capable of high-speed output involved in the present invention include various fiber cloths, papers, and fabrics, etc., and for convenience of description, they are collectively referred to as "dyeed objects" hereinafter.

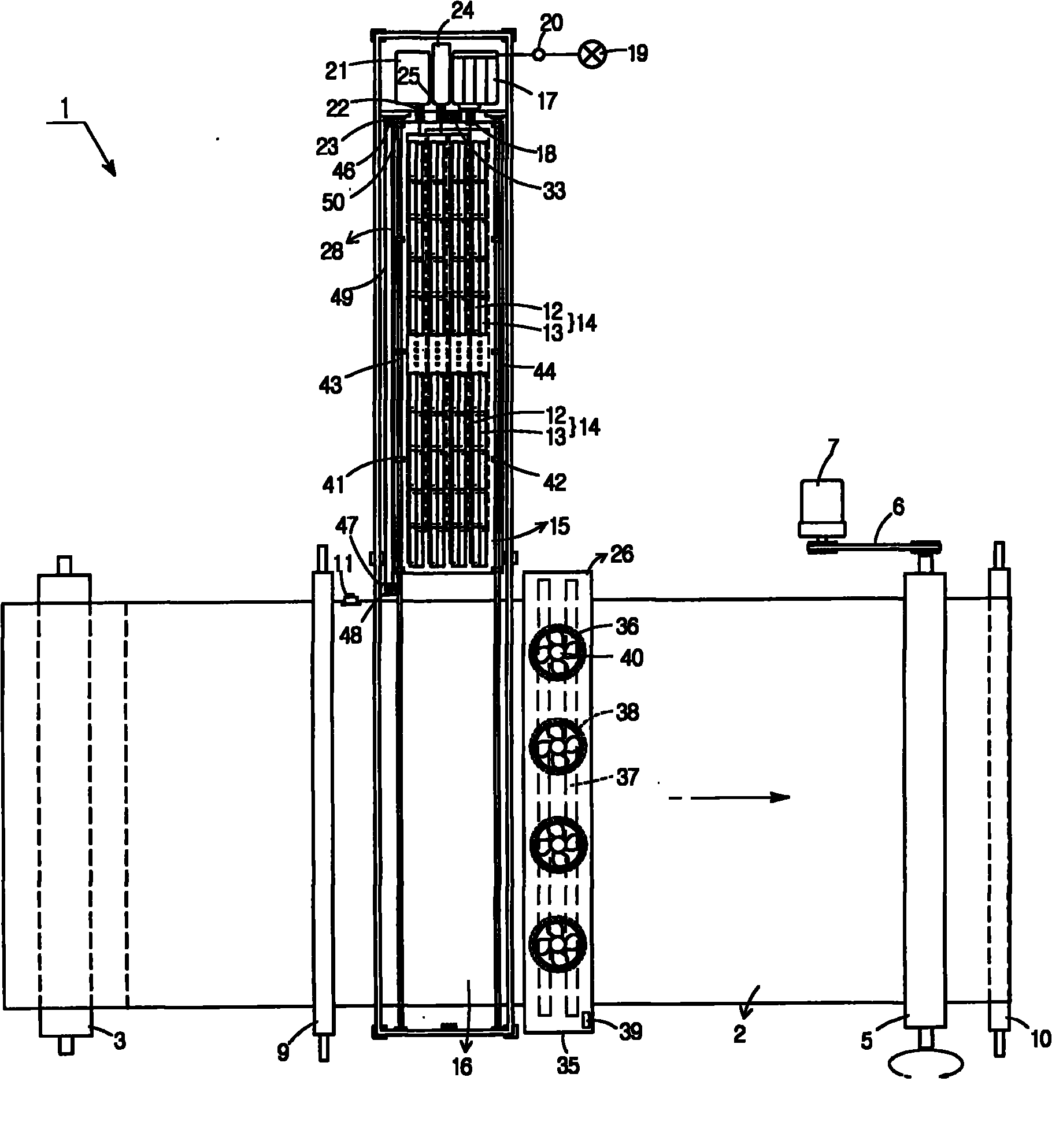

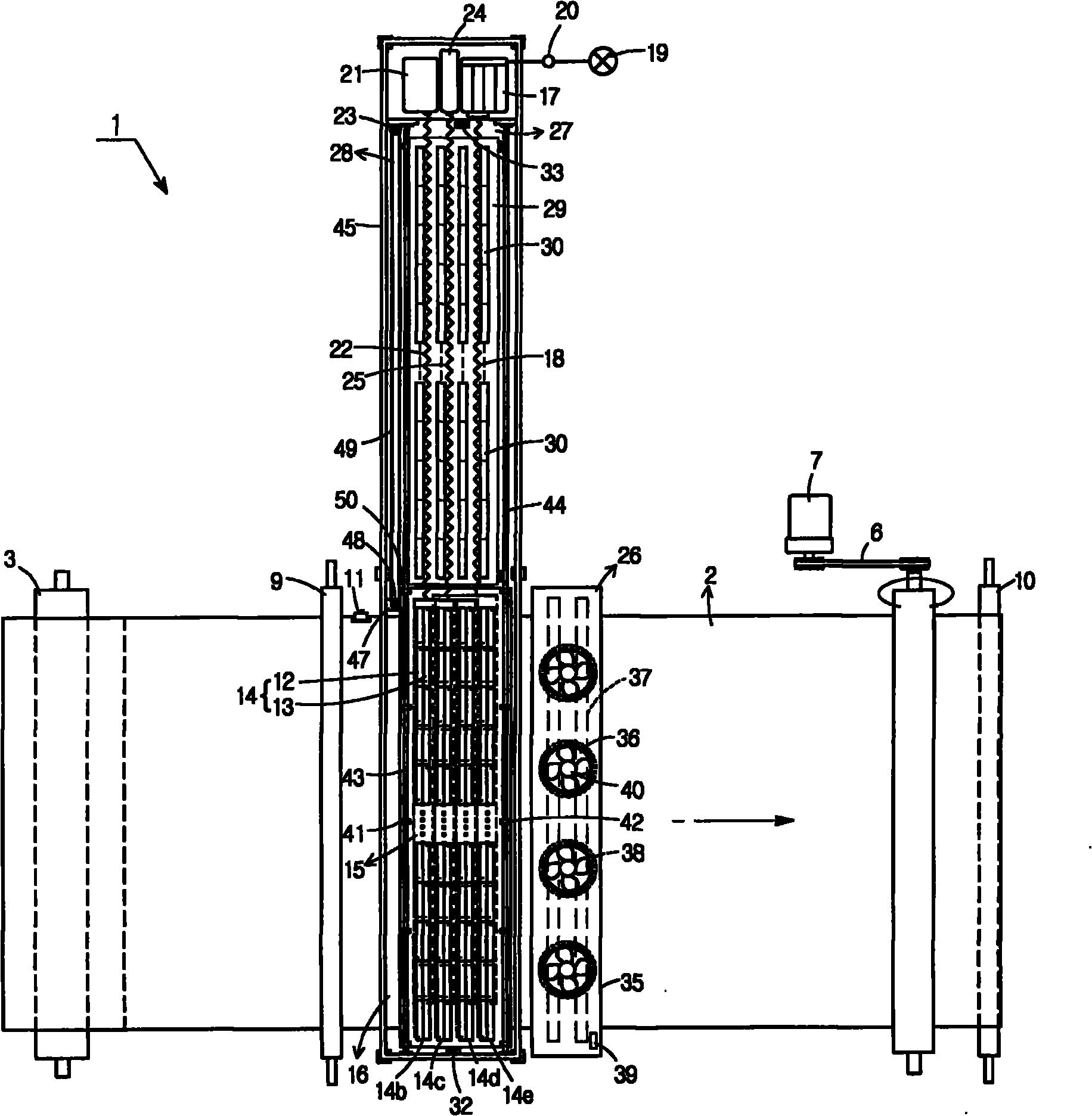

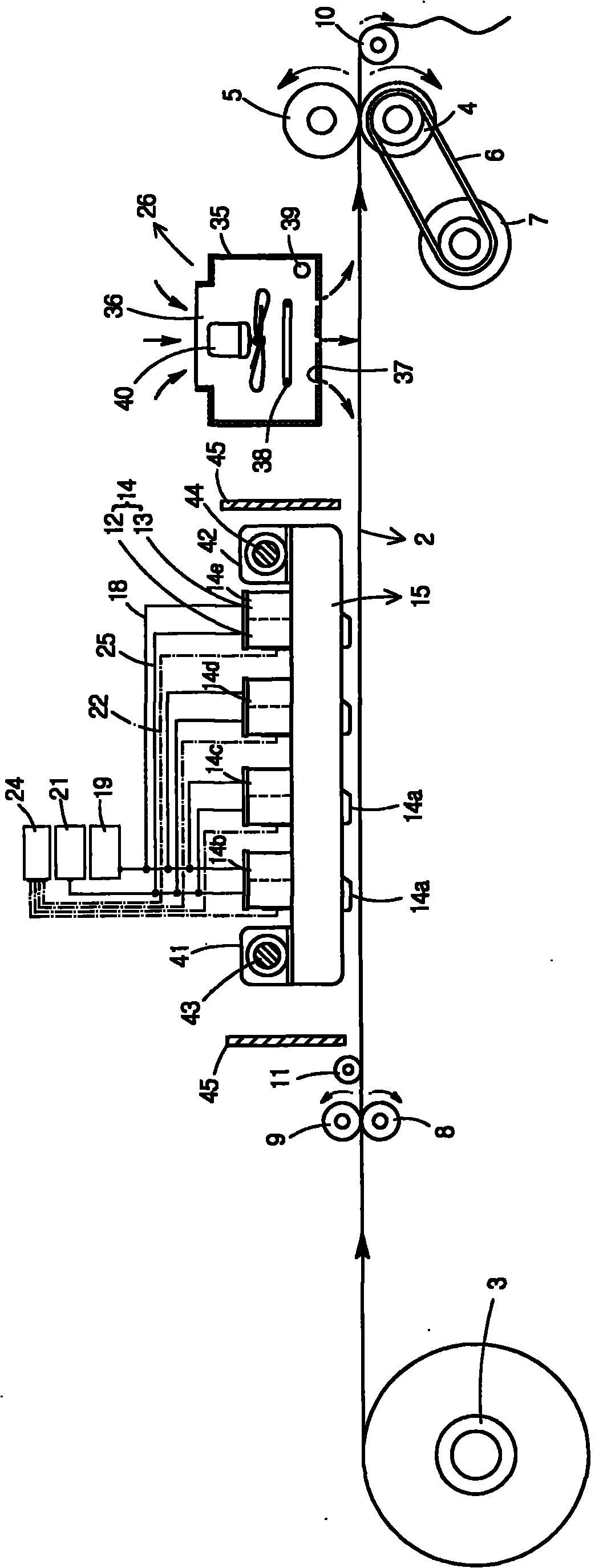

[0049] The digital printing high-speed output device 1 of the present invention includes: a supply cylinder 3 wrapped with a certain width of the dyed object 2; a pair of upper and lower active cylinders 4 for leading out the dyed object 2 on the supply cylinder 3 to make it move forward; Passive drum 5; a power transmission device 6 and a servo motor 7 used to rotate the active drum 4 at a constant speed (or at a speed controlled by the controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com