Unidiameter well drilling and completing method

A technology of equal diameter, drilling and completion, applied in drilling equipment and methods, drilling equipment, earthwork drilling, etc., can solve the problems of complex construction process and high construction cost, and achieve the effect of simple construction process and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

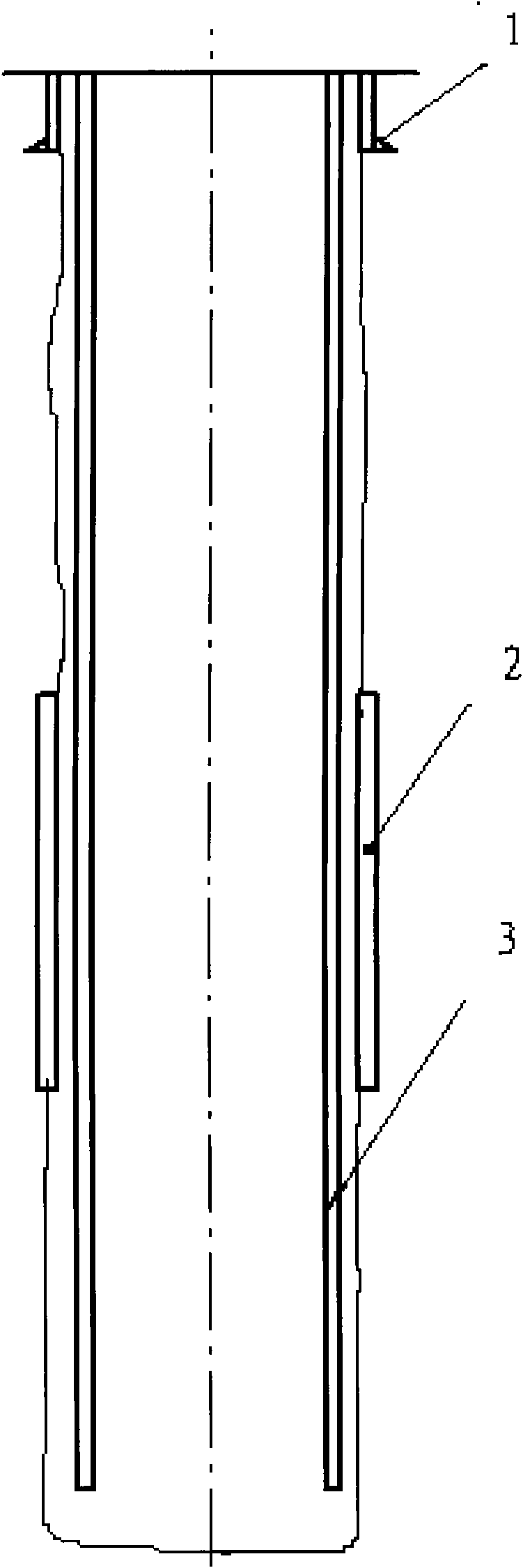

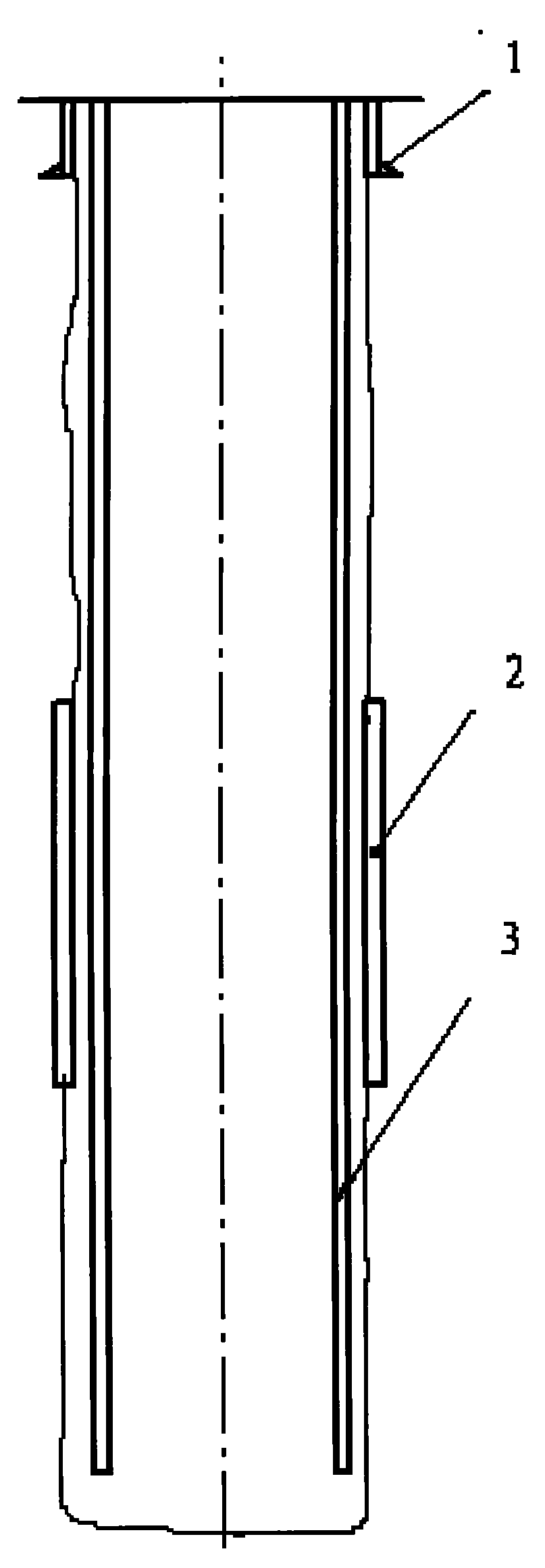

[0008] As shown in the attached figure, it is a drilling and completion method with equal diameter. After the surface casing 1 is run, the wellbore is drilled with a suitable drill bit. down into the expansion tube 2, expand the expansion tube 2 by mechanical or other methods, so that the inner diameter of the expansion tube 2 is as large as the hole drilled by the original drill bit, and then drill with the original size drill bit until the next one that needs to be sealed is encountered. For the well section, repeat the above steps until all the wells are drilled, and run a completion casing 3 of an appropriate size in the wellbore to achieve equal-diameter completion.

[0009] The expansion pipe 2 used in the present invention does not have high requirements on strength and less consumption. The cost of the same well is far lower than that of the existing diameter drilling and completion method, and the construction difficulty is greatly reduced.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap