Driller tower hoisting device and using method thereof

A technology for a tower and a drilling rig, which is applied in the field of a tower lifting device for a drilling rig, can solve the problems of high safety risk, increased cost and high cost, and achieves the effects of high safety, saving installation and construction costs, and facilitating construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

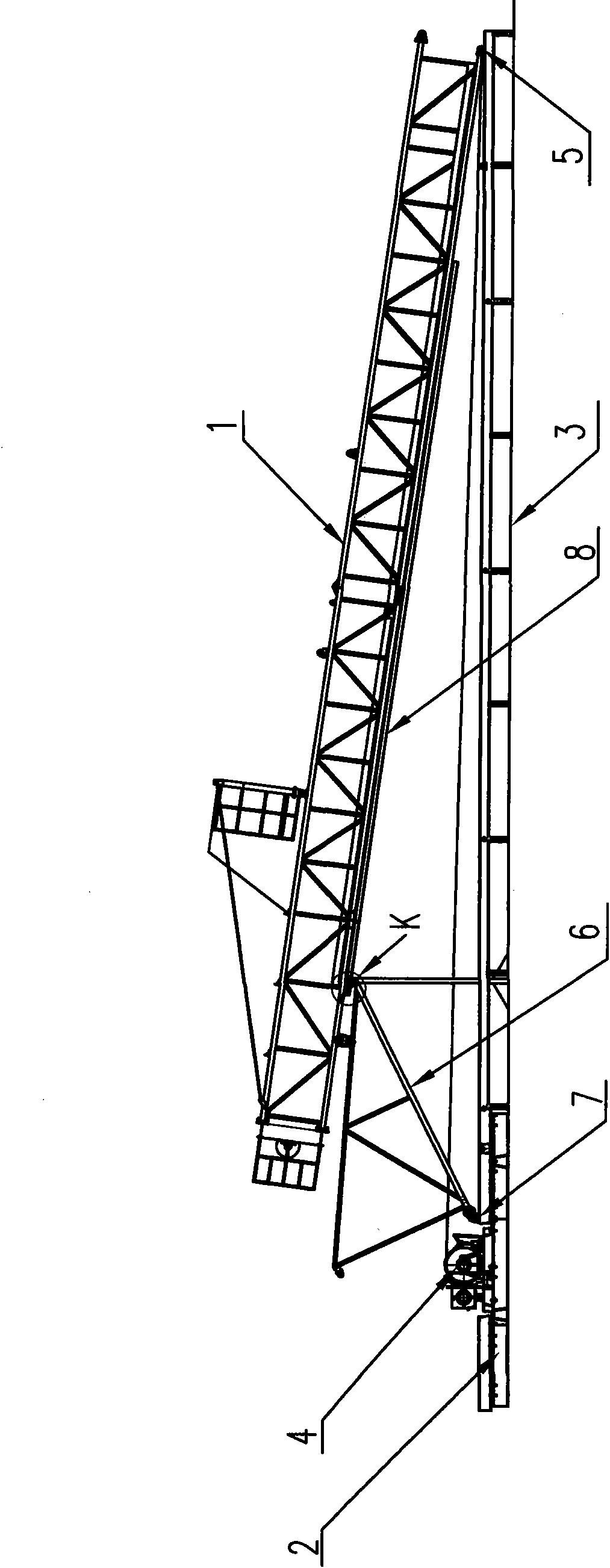

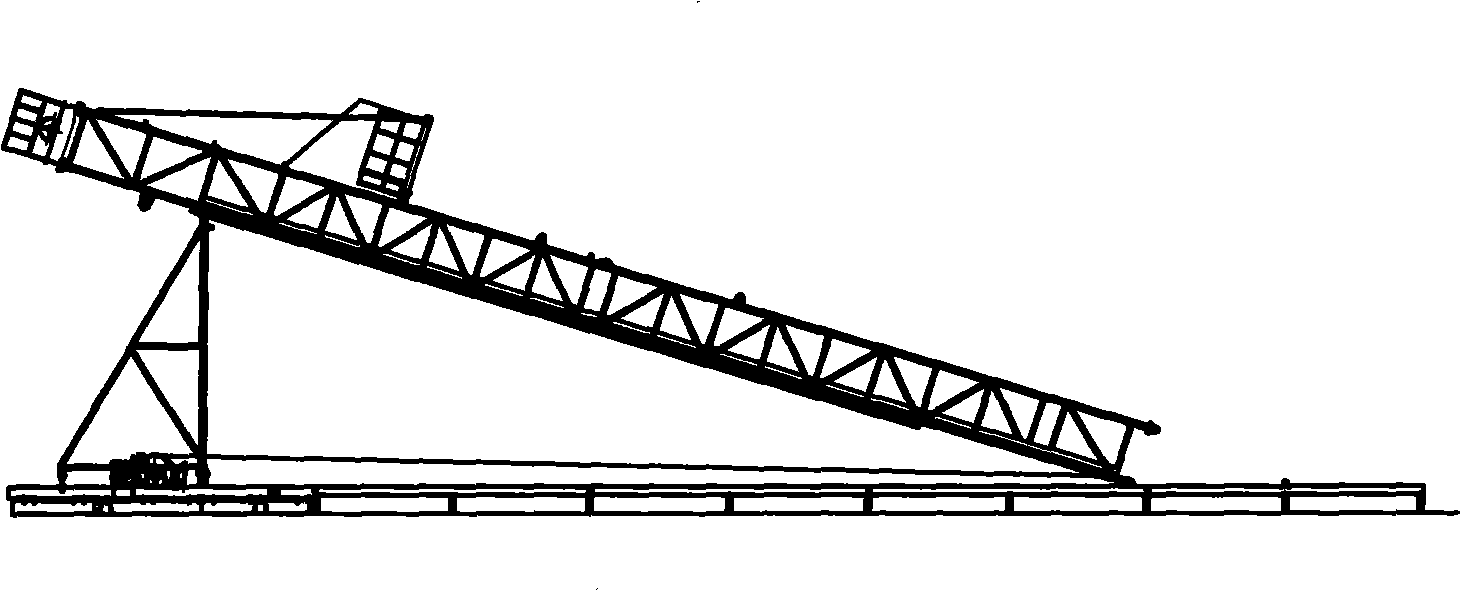

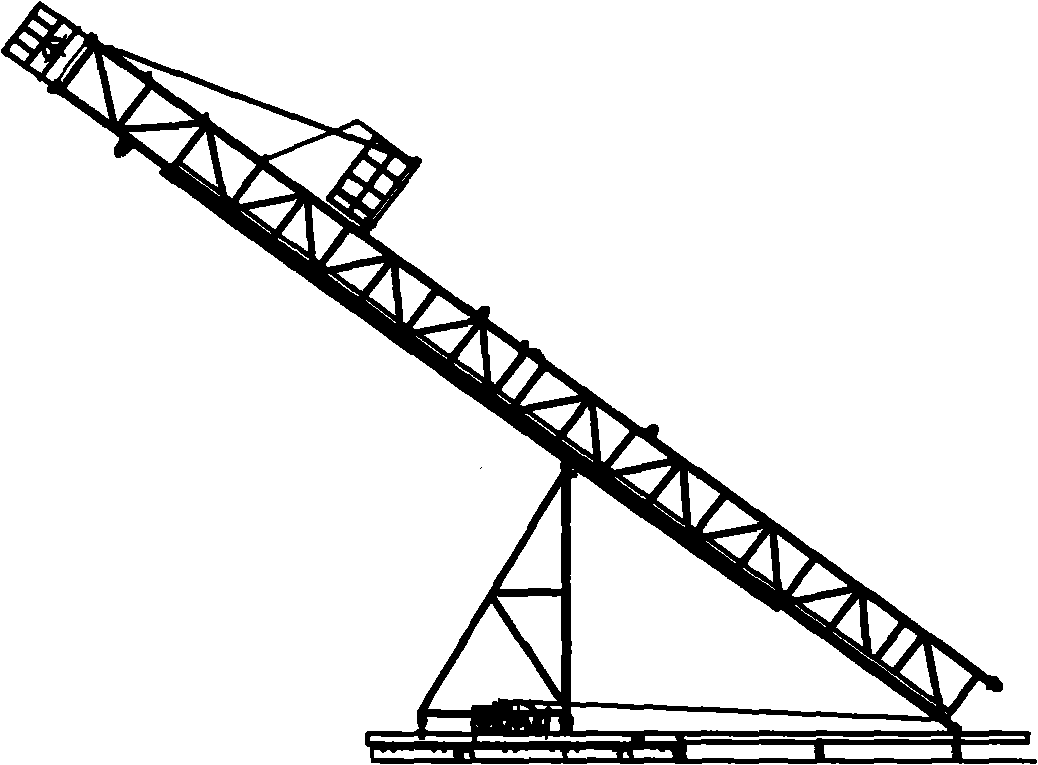

[0020] see figure 1 , a drilling rig tower lifting device, including a drilling rig tower 1, a tower base 2, a ground guide rail 3 and a hoist 4, the tower base 2 is fixed on one end of the ground guide rail 3, and the drilling rig tower 1 is placed on the ground guide rail 3 Above, the foot of the drilling rig tower 1 is provided with a pulley 5, which can move back and forth on the ground guide rail 3; the surface of the tower base 2 is equipped with a hoist 4, and the wire rope of the hoist 4 is connected to the lower part of the drilling rig tower 1 through the pulley; the tower lifting device It also includes a triangular bracket 6, which adopts a right triangle or an obtuse triangle bracket, and one end point of the triangular bracket 6 is hinged with the tower base 2 through a pin 7.

[0021] see figure 2 , The side of the drilling rig tower 1 is provided with a guide rail 8, and the other end point of the tripod 6 is slidably matched with the guide rail 8 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com