Gate roadway head-on turning transverse construction method

A construction method and roadway technology, applied in the field of excavation technology, can solve problems such as low efficiency, high labor intensity of workers, and poor safety, and achieve the effects of improving safety factor, reducing electromechanical accident rate, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

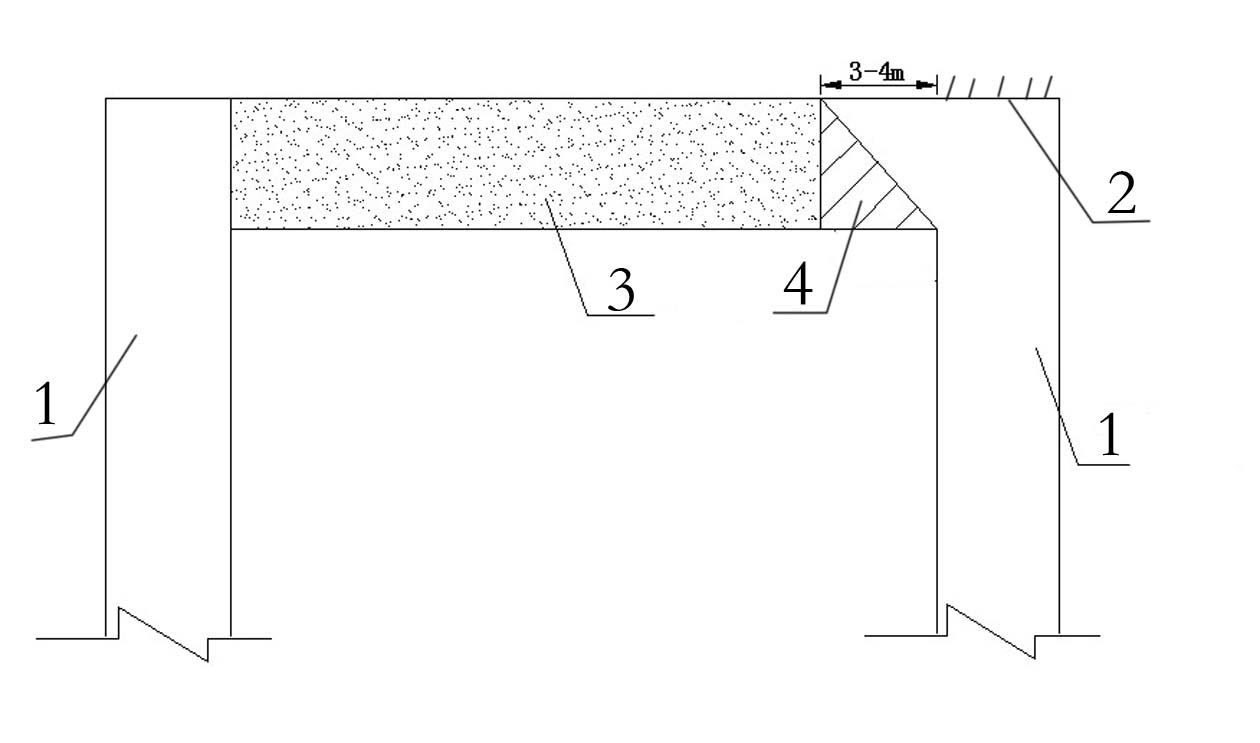

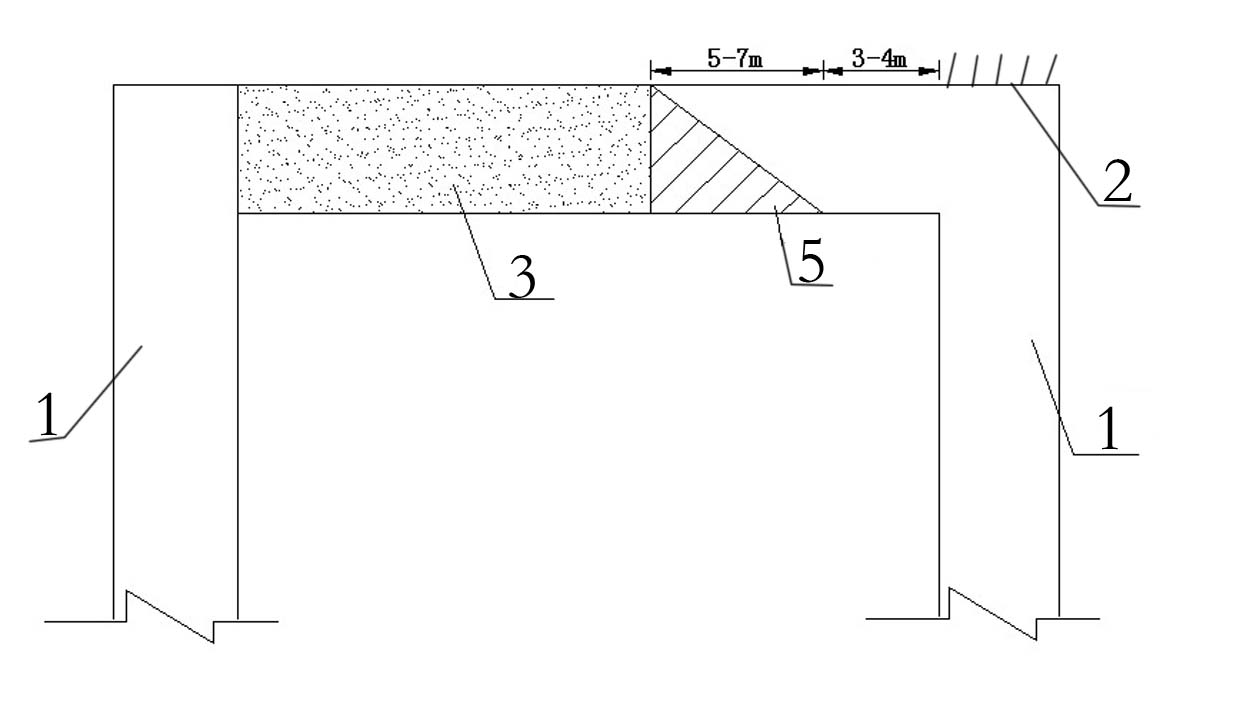

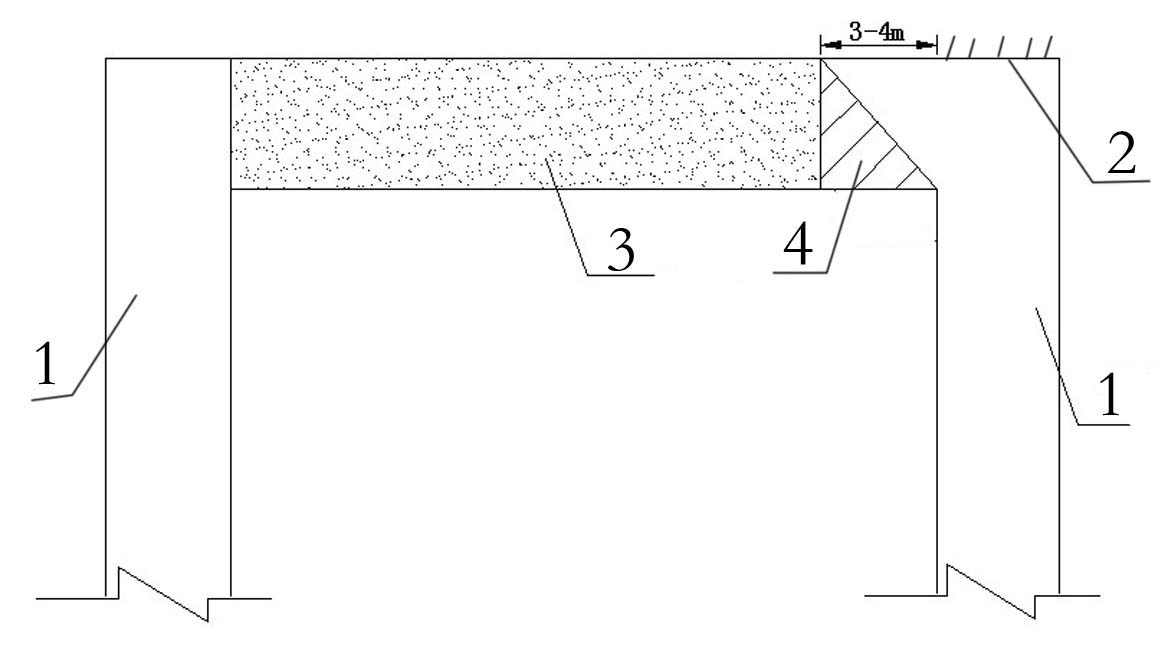

[0015] The construction method of turning head-on and crossing the tunnel roadway is realized by the following steps:

[0016] First: Belt conveyors are used for transportation during tunneling. Before turning, the tail of the belt conveyor is retracted one shift in advance, and a 40-ton slide (scraper conveyor) is installed on the belt conveyor to ensure that the unit (excavation) before turning machine) excavation along the chute, the chute is moved to the side of the tunnel roadway opposite to the position of the traversing opening, the head of the chute is 30 meters away from the side of the opening, the cutting head of the unit is at the traversing opening, and the reload of the unit rides on the smooth part of the chute; excavation along the trough roadway During the transportation process, slides are used, and the slides only need to be moved to the side of the roadway opposite to the position across the opening;

[0017] Second: Change the pin connection between the un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com