Gasoline engine

A gasoline engine and crankcase cover technology, applied in the direction of engine components, machine/engine, engine lubrication, etc., can solve the problems of shortening the service life of bearings, lack of lubricating oil for bearings, and effective lubrication for moving parts, etc. Achieve cost savings and smooth crankshaft rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

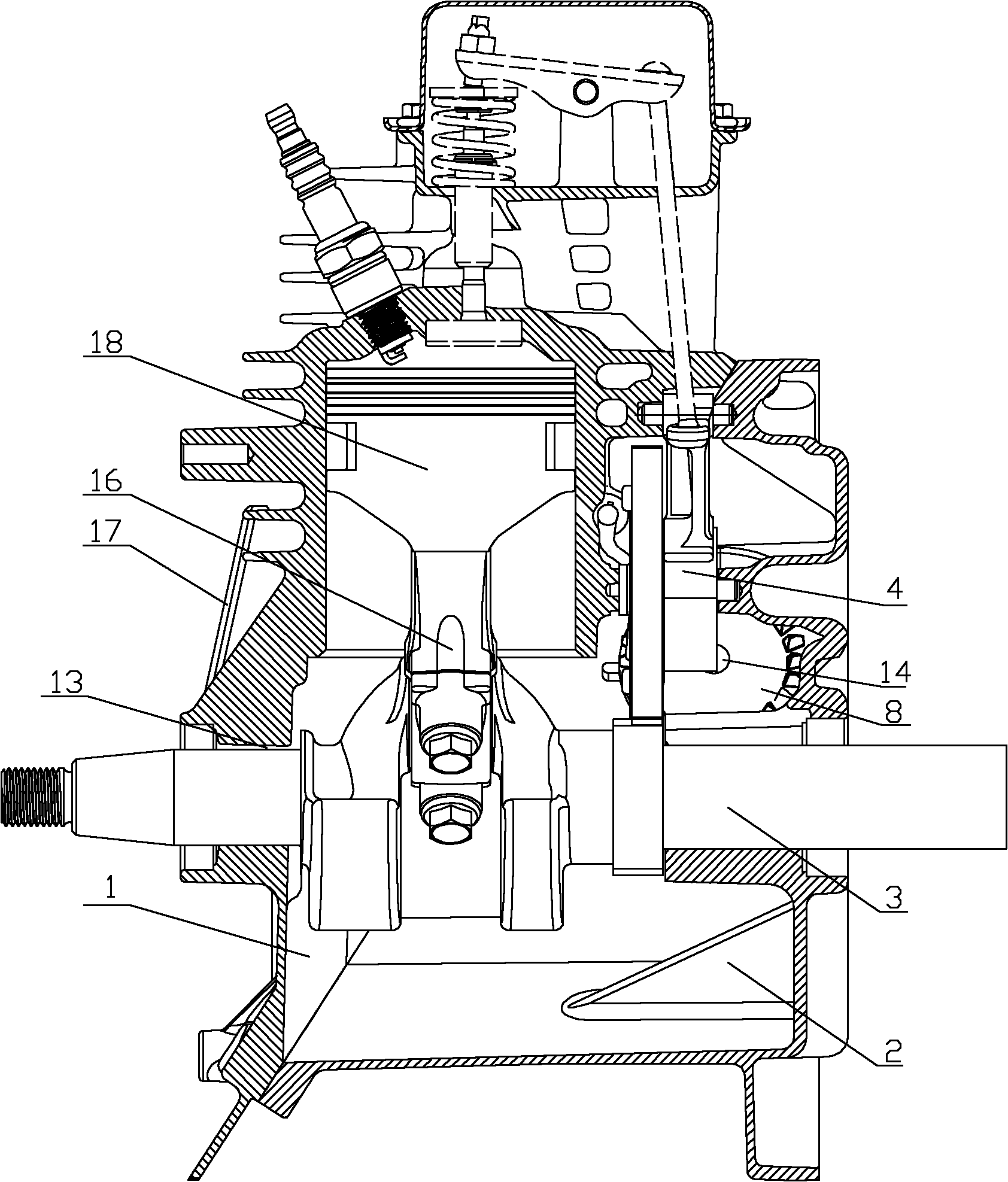

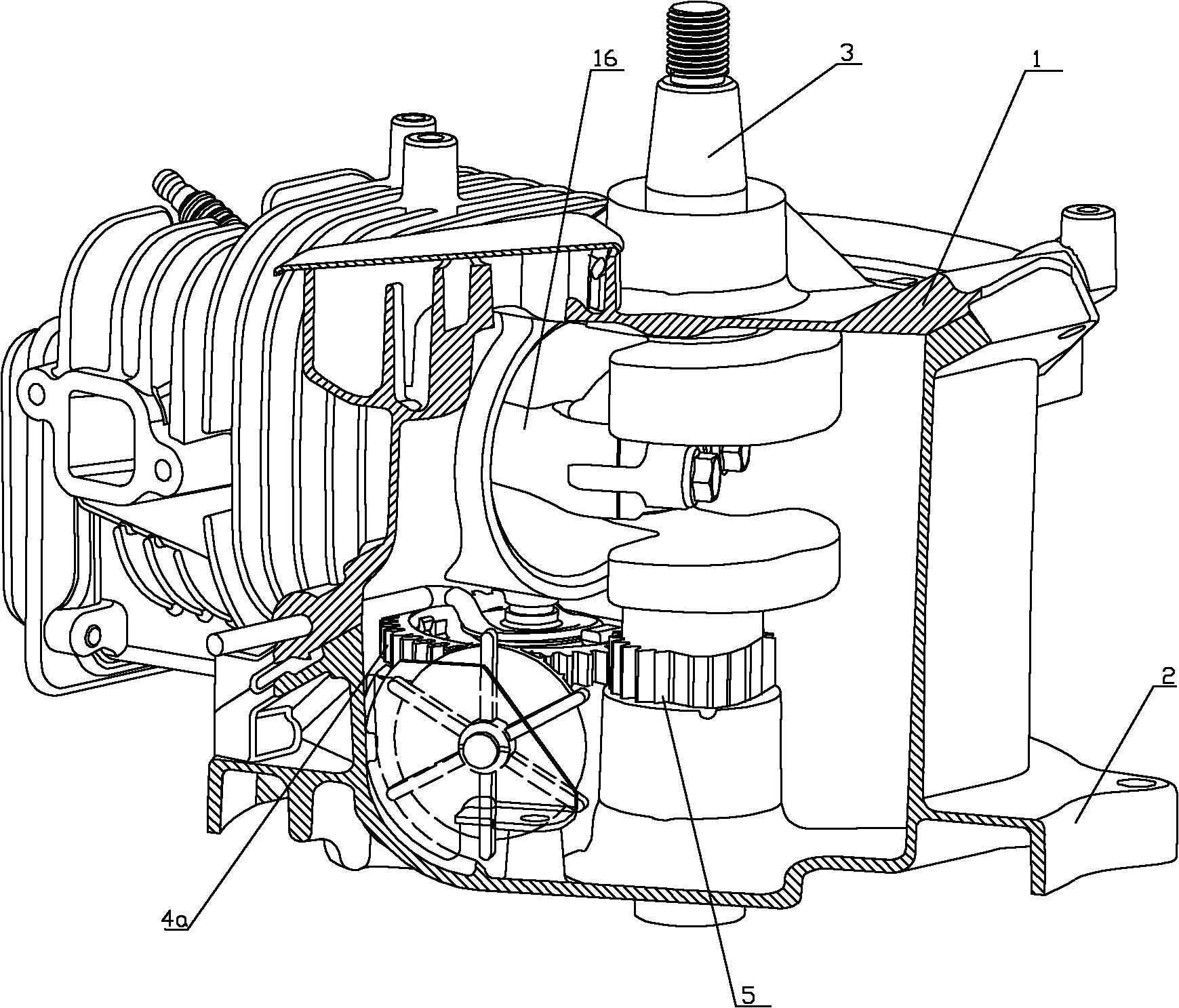

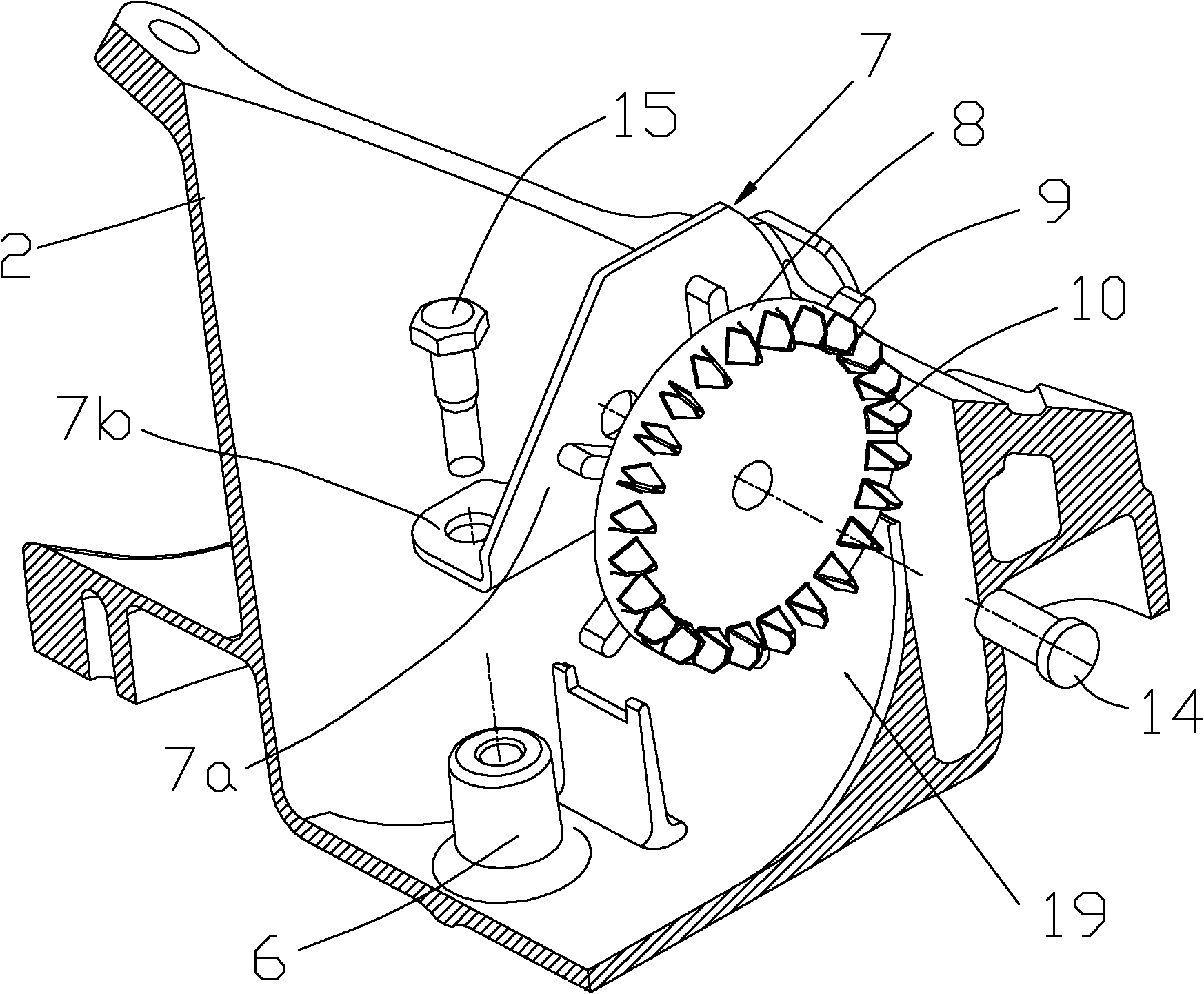

[0017] refer to Figure 1 to Figure 4 , the cylinder of the gasoline engine and the crankcase body 1 have an integrated structure, the crankcase cover 2 is combined with the crankcase body 1 provided with the cylinder, and the joint surface of the crankcase cover 2 and the crankcase body 1 is a corresponding slope, both Combined to form the inner cavity of the engine crankcase. The two ends of the crankshaft 3 of the crankshaft linkage mechanism are respectively rotatably supported on the crankcase body 1 and the crankcase cover 2 , and the crankshaft support hole 13 on the crankcase body 1 is slidably matched with the crankshaft 3 . One end of the connecting rod 16 of the crankshaft-connecting rod mechanism is hinged with the crankshaft 3, and the other end is hinged with the piston 18, and the piston 18 is located in the cylinder. The crankshaft 2 is provided with a timing gear 5 which rotates together with the crankshaft 3 . The timing gear 5 meshes with the gear 4a of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com