Composite oil-gas separation device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

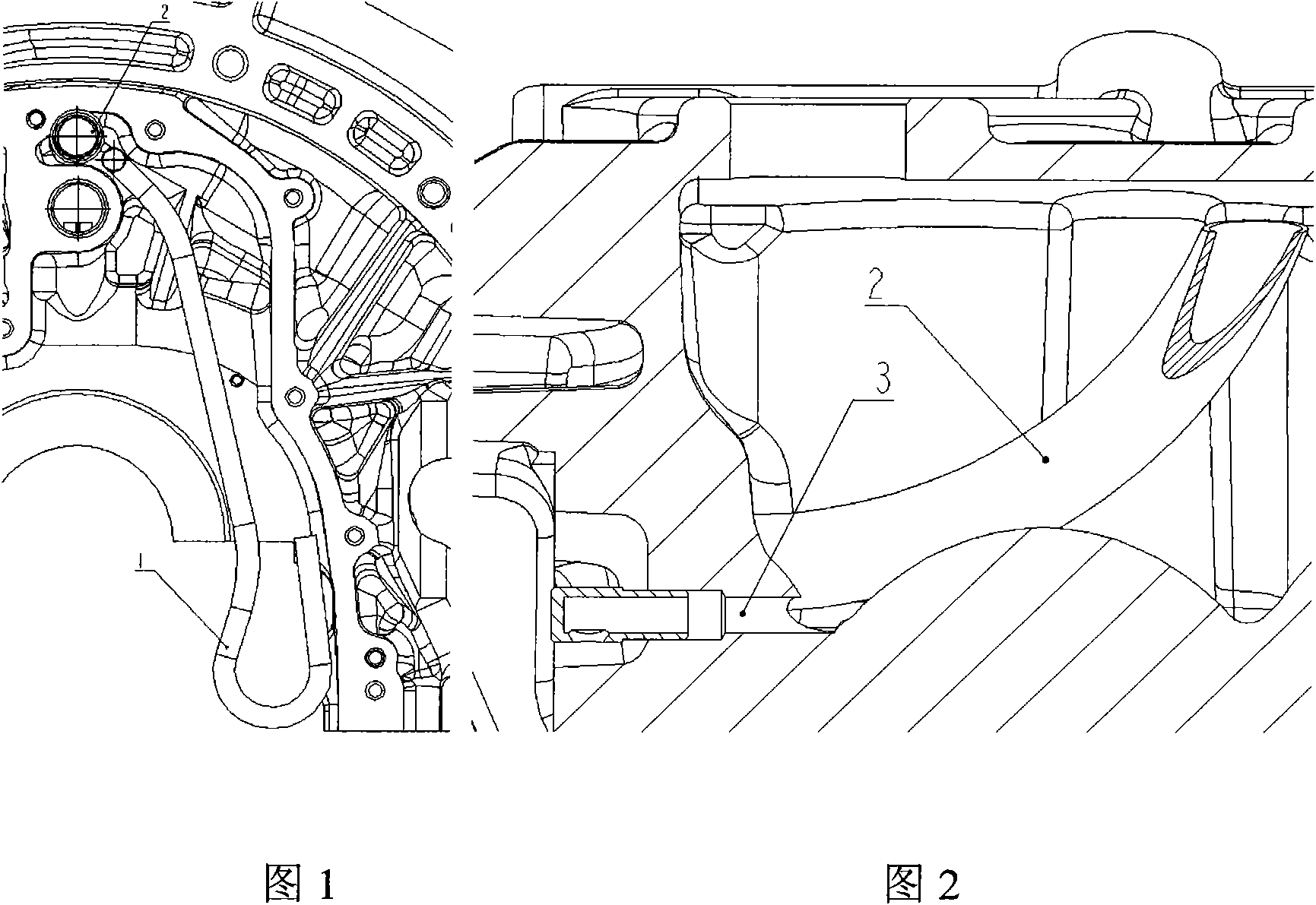

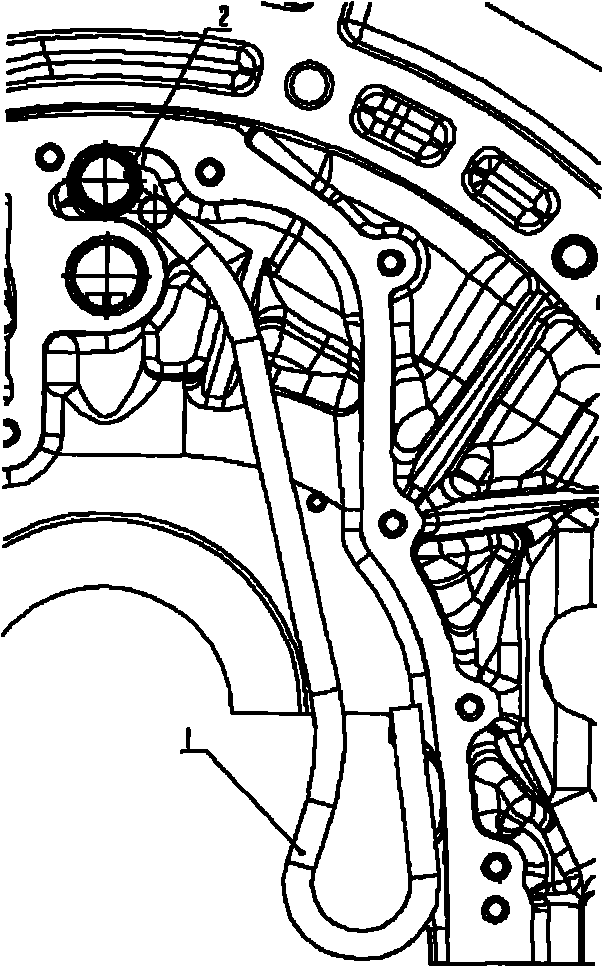

[0009] Below in conjunction with accompanying drawing, the present invention will be further described: as figure 1 As shown in -3, a compound oil-gas separation device is characterized in that: the gas guide pipe 1 and the oil return pipe 2 are connected at the air inlet of the oil-gas separation chamber at the rear end of the V-shaped engine, and the oil return pipe 2 is a "J"-shaped pipe It communicates with the oil pan; the oil return pipe inlet 3 is arranged at the bottom of the oil-gas separation chamber.

[0010] When the engine is running at high speed and heavy load, the oil-air mixture entering the oil-gas separation chamber enters the oil-gas separation chamber through the gas guide pipe 1, and the gas guide pipe 1 changes the direction of gas flow, so that the gas collides with the wall of the oil-gas separation chamber, thereby reducing the The flow rate of the oil-air mixture increases the separation capacity of the oil-gas separation chamber; at the same time, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com