Method for doping graphene in stationary phase of gas chromatographic column

A gas chromatographic column and graphene technology, applied in the field of analytical chemistry, can solve the problems of weak polarity of stationary phase, increase the roughness of the inner wall of capillary, single structure of stationary phase coating material, etc., and achieve strong Π-Π conjugated force. , Solve the effect of unstable fixation and high practical application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]Embodiment one: the steps of traditional sodium chloride deposition method are as follows:

[0041] First, 10 g of solid sodium chloride powder was added to 40 ml of methanol five times at 2 g / time, ultrasonically dissolved, and left to settle to form a saturated methanol solution of sodium chloride.

[0042] Add 2ml of sodium chloride saturated methanol solution to a 50ml flat-bottomed flask, add a rotor, place it on a magnetic stirrer and stir vigorously, keep stirring, add 10ml of chloroform solution to it and continue stirring for 5min, then add 10ml to the mixed liquid Chloroform and stirred for 2min.

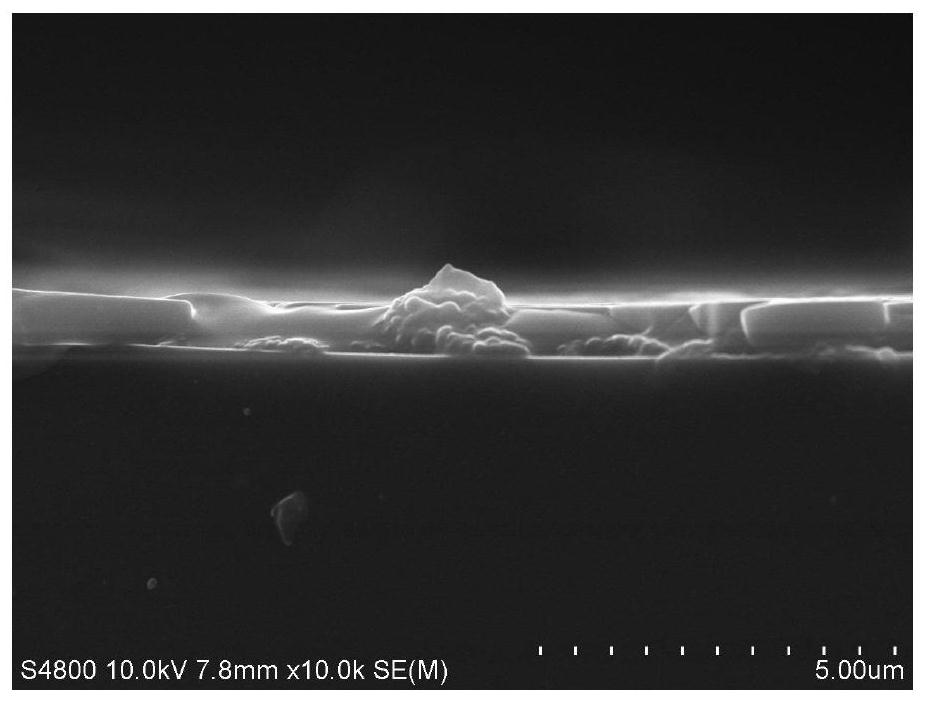

[0043] Move the mixed solution into a positive pressure container, make the mixed liquid pass through the cleaned capillary through the pressure, fully absorb, and transfer the whole capillary to the gas chromatography column thermostat after the liquid is emptied, pass nitrogen at 120°C for 180 minutes to obtain sodium chloride roughened capillary.

Embodiment 2

[0044] Embodiment two: sodium chloride deposition method simultaneously introduces the steps of graphene oxide as follows:

[0045] First, 10 g of solid sodium chloride powder was added to 40 ml of methanol five times at 2 g / time, ultrasonically dissolved, and left to settle to form a saturated methanol solution of sodium chloride.

[0046] Next, 0.04 g of single-layer graphene oxide was added to 40 ml of chloroform, and the mixed solution was ultrasonically pulverized for 180 min to form a uniform suspension.

[0047] Add 2ml of sodium chloride saturated methanol solution to a 50ml flat-bottomed flask, add a rotor, place it on a magnetic stirrer for vigorous stirring, keep stirring, add 10ml of trichloromethane suspension to it and continue stirring for 5min, add to the mixed liquid Continue to add 10ml of chloroform suspension and continue to stir for 2min.

[0048] Move the mixed solution into a positive pressure container, and use the pressure to make the mixed liquid pas...

Embodiment 3

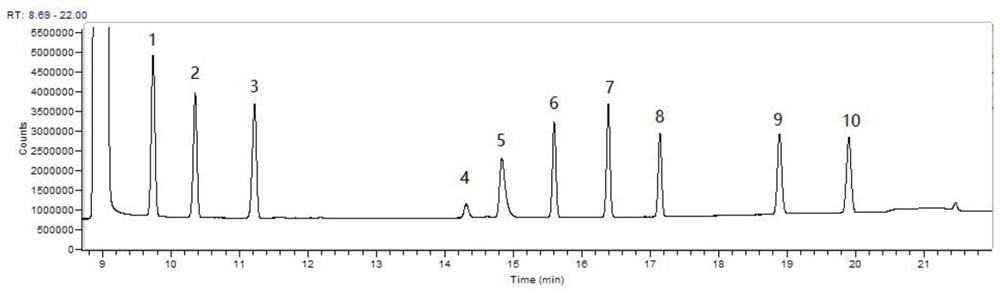

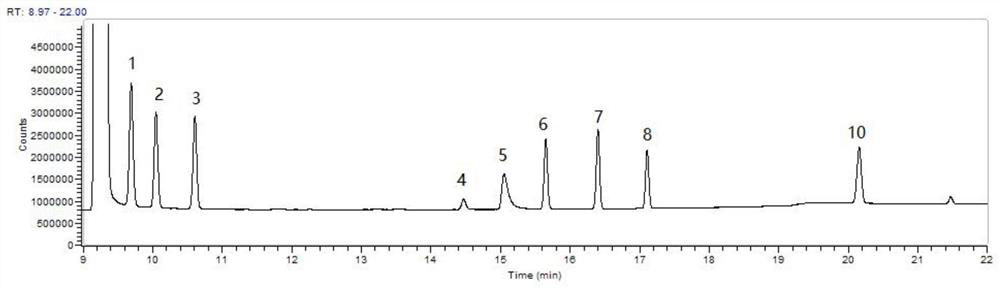

[0049] Embodiment three: the preparation steps of the ionic liquid chromatographic column doped with monolayer graphene oxide in the stationary phase are as follows:

[0050] The roughened capillaries in Examples 1 and 2 were taken for use; the ionic liquid (see Chinese invention patent for details: a dicationic imidazole-based ionic liquid and its preparation method) was prepared as 1% m / v The coating solution is ready for use; take 1g of glyceryl stearate and heat it up to 80°C to liquefy it for use;

[0051] ① Move the coating liquid into a positive pressure container, connect the capillary in Example 1, and pass the positive pressure to fill the capillary with the coating liquid;

[0052] Stop the injection pressure, one end of the capillary is sealed by glyceryl stearate, and the other end is connected to the static coating capillary column in the vacuum pump;

[0053] Put the coated capillary chromatographic column into a gas chromatograph column oven at 120°C for aging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com